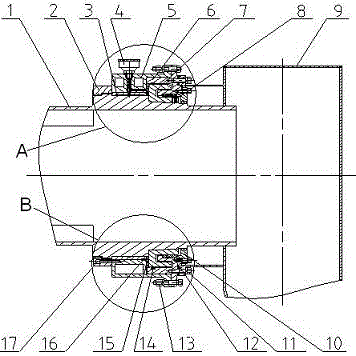

Movable sealing connection device of rotary furnace

A connecting device and dynamic sealing technology, which is applied to the sealing of engines, rotary drum furnaces, furnaces, etc., can solve the problems of inconvenient installation, complex structure, and wear of parts, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

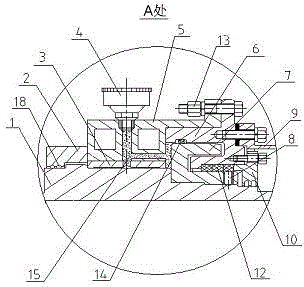

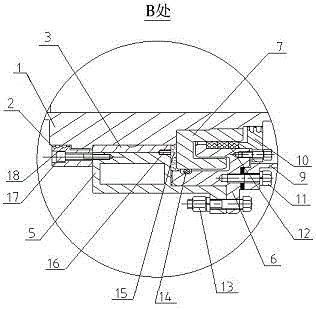

[0029] Example: A preferred embodiment of the present invention is that a copper sleeve 3 is movably fitted on the rotary cylinder 1 so that there is a gap of 0.3-1 mm between the copper sleeve 3 and the rotary cylinder 1 . The copper sleeve 3 is provided with an oil hole, and adopts an interference fit with the water-cooled bearing seat 5, and is fixedly connected with the seam bolt 16 . The gland 2 is fixed on the water-cooled bearing seat 5 through bolts 17, and the gland is processed with labyrinth grooves and steps to clamp the rotary cylinder 1. The inner labyrinth ring 7 is made of cast iron, and its inner hole fits with the rotary cylinder 1 with a gap of 0.01-0.06mm, and is fixed on the rotary cylinder 1 by set screws 8, and the rotary cylinder 1 is made of heat-resistant stainless steel. The labyrinth cover 6 is connected and fixed with the water-cooled bearing seat 5 with bolts 13 . The labyrinth cover 6 and the inner labyrinth ring 7 form a labyrinth seal, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com