Multi-way valve with single oil duct and double valve elements in parallel connection and used for high-power excavator

A double-spool, parallel-connected technology, which is applied to mechanically driven excavators/dredgers, valve details, multi-way valves, etc., can solve the problem of large pressure loss in the hydraulic system, failure to meet high power requirements, and small flow area, etc. problems, to achieve the effects of simplified structure, guaranteed sealing performance, and simple connection of external pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

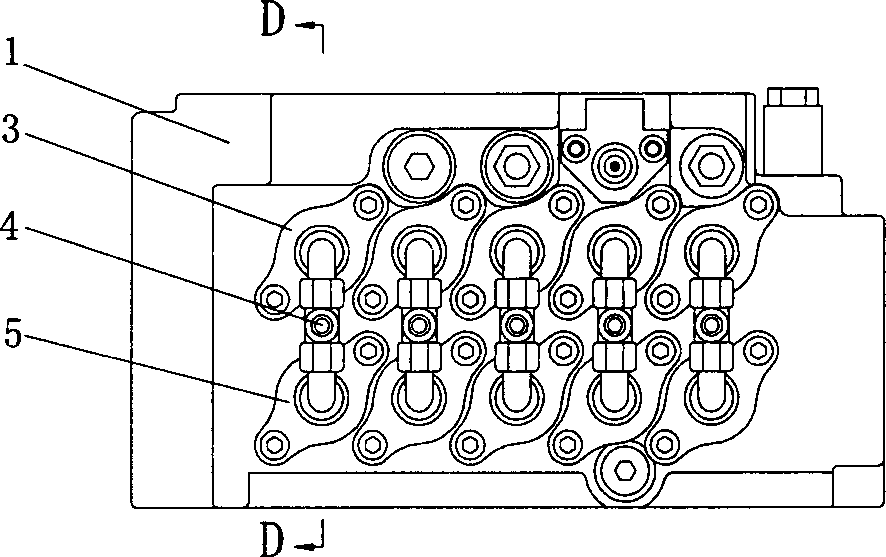

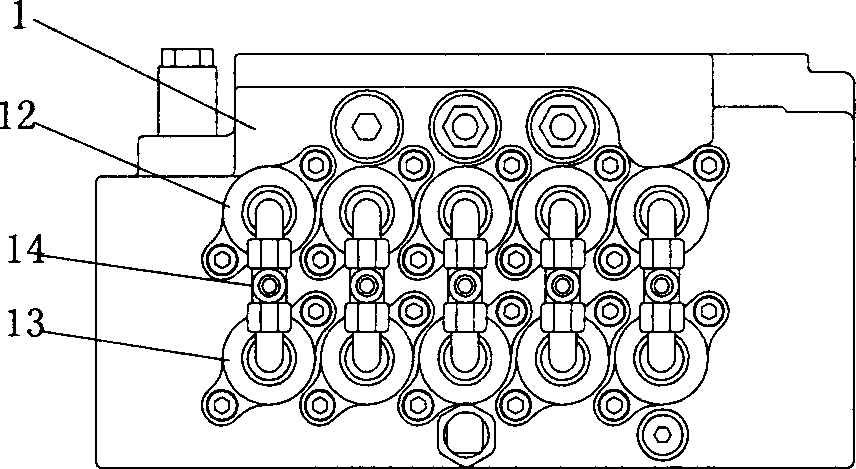

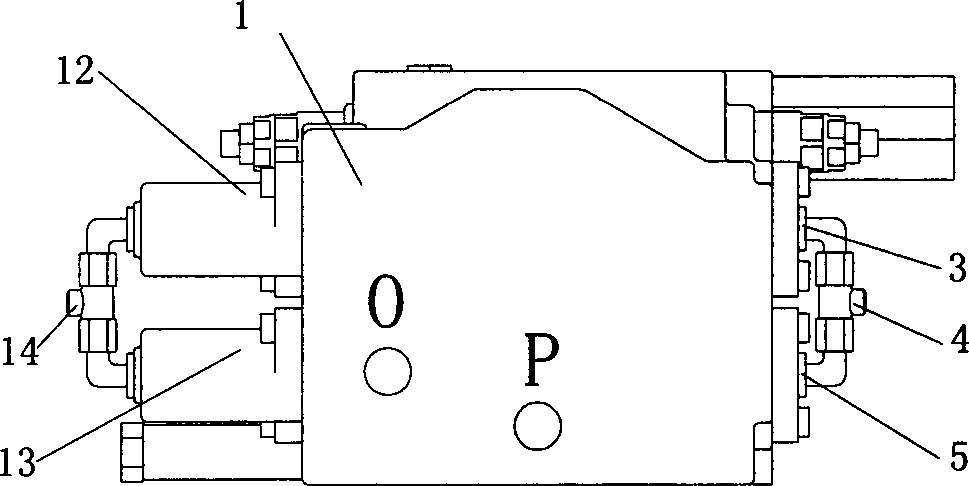

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a multi-way valve for large-scale excavators with a single oil channel and double spools in parallel includes a spool 2, an end cover 3 is installed on one end of the spool 2, and a pilot control valve assembly 12 is installed on the other end. The end cover 3 is connected with the pilot control port pA port 4, the pilot control valve assembly 12 is connected with the pilot control port pB port 14, and the working oil circuit, the oil inlet circuit and the oil return circuit of the spool 2 are connected in parallel with the spool 2 Auxiliary spool 6 with the same structure; one end of the auxiliary spool 6 is equipped with an auxiliary spool end cover 5, the other end is equipped with an auxiliary spool pilot control valve assembly 13, and the pilot control port pA port 4 is connected to the auxiliary spool end Cover 5, pilot control port pB port 8 is connected to auxiliary spool pilot control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com