Novel construction method for heat insulation of heat-insulating pipeline joints

A technology for pipe joints and construction methods, which is applied in the direction of protecting pipes, pipes/pipe joints/fittings, and pipe protection through heat insulation, and can solve problems such as poor sealing performance of heat-insulated pipe joints, hidden dangers of sealing performance, and decline in heat-insulation performance of heat-insulated pipes. Achieving excellent mechanical and sealing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

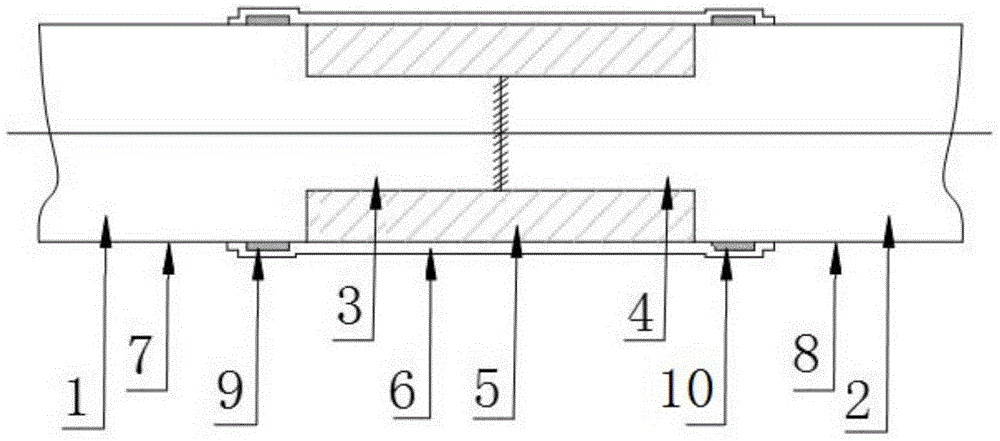

[0046] This embodiment provides a new construction method for insulation of heat-insulated pipe joints, including

[0047] A. The step of joining the exposed ports of the working pipes 3, 4 of the adjacent two sections of heat-insulated pipelines 1, 2 to form an interface area;

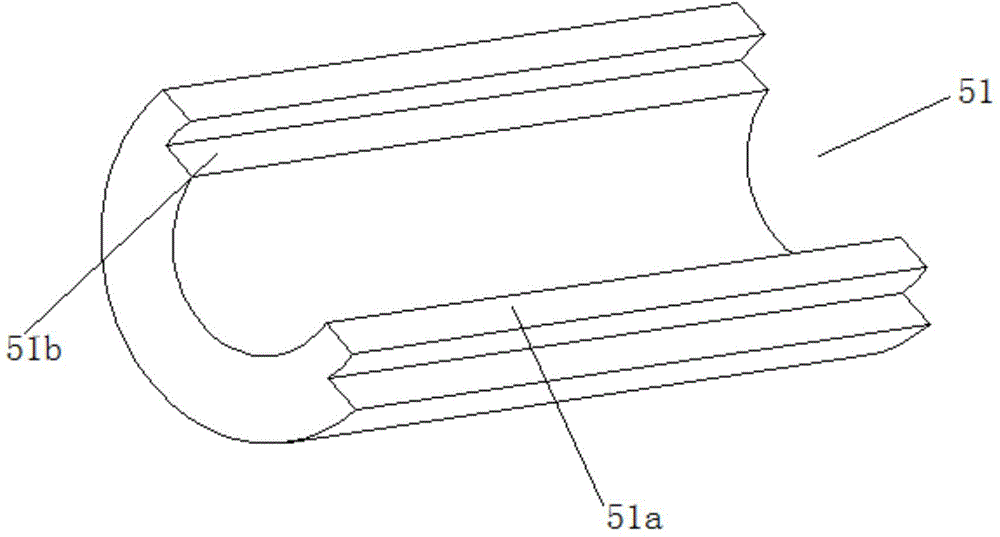

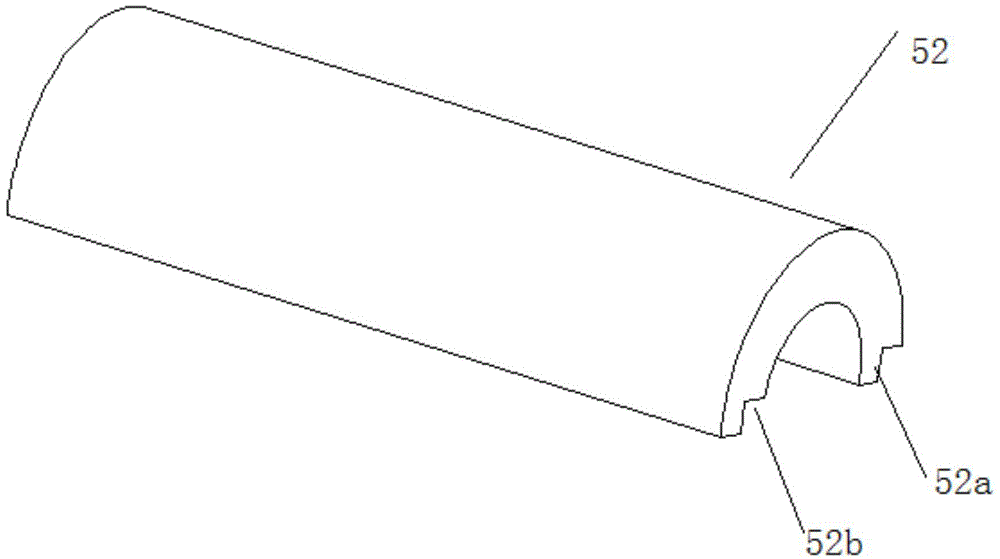

[0048] B. The step of using prefabricated polyurethane foam tiles to form the heat insulating layer 5 in the installation area;

[0049] C. The step of forming an outer sheath on the outer wall of the heat insulation layer 5 and part of the outer walls of the outer sheath pipes 7, 8 of the adjacent two sections of heat insulation pipelines 1, 2, in the step of forming the outer sheath, first Install sealing strips 9, 10 in the installation area adjacent to the outer walls of the outer protective tubes 7, 8, and then set a heat-shrinkable sleeve 6 on the outer wall of the heat-insulating layer 5 as an outer sheath, and the heat-shrinkable The two ends of the sleeve 6 are respectively overlapped on the...

Embodiment 2

[0062] This embodiment provides a new construction method for thermal insulation of heat-insulated pipe joints, which is a deformation on the basis of Embodiment 1. In this embodiment, after the formation of the thermal insulation layer 5 during construction, the thermal insulation The outer wall of the layer 5 is fitted with a plastic film as a barrier layer, and the barrier layer is located between the outer wall of the heat-insulating layer 5 and the inner wall of the heat-shrinkable sleeve 6 to prevent the heat-shrinkable sleeve from The gas in the thermal insulation layer 5 inside 6 and / or the gas and moisture in the external environment pass through the barrier layer that circulates through the heat-shrinkable sleeve 6 .

[0063] During the use of the heat-insulating pipe joint, when the gas or moisture in the external environment penetrates into the barrier layer through the tube wall of the heat-shrinkable sleeve 6, it is blocked by the barrier layer, so that the gas or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com