Adjustable fluid-solid coupled similar material for model test and preparation method of adjustable fluid-solid coupled similar material

A model test, similar material technology, applied in the field of material science, can solve the problems of poor similarity simulation, disintegration in water, small adjustable range of compressive strength and permeability coefficient, etc., to meet the requirements of reducing maintenance conditions and improving similarity Simulation degree, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

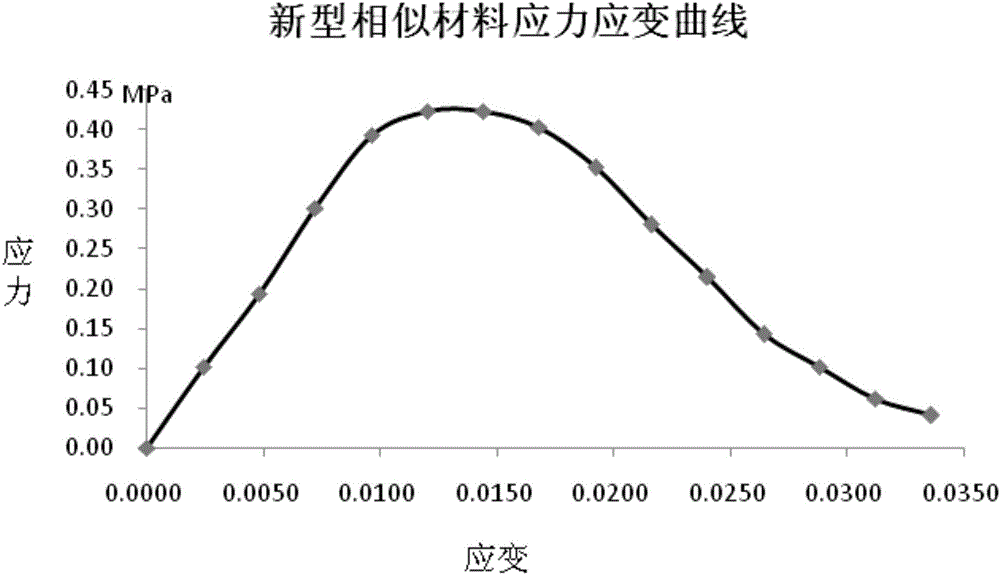

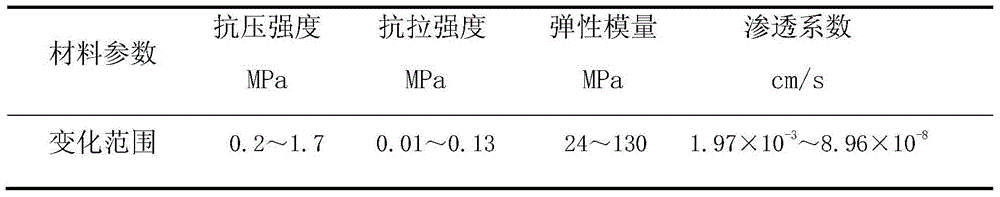

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of adjustable fluid-solid coupling similar materials for model tests

[0032] The raw material composition is: 1 part of standard sand, 0.11 part of calcium carbonate, 0.08 part of barite powder, 0.06 part of cement, 0.13 part of water, 0.02 part of silicone oil, and 0.14 part of chlorinated paraffin.

[0033] The preparation method is:

[0034] 1) Weigh the standard sand, calcium carbonate, barite powder and cement in proportion;

[0035] 2) Mix the weighed standard sand, calcium carbonate, barite powder, cement and other four fine-grained materials and stir evenly;

[0036] 3) Weigh the mixing water, add the fine-grained material obtained in step 2) to mix, and stir thoroughly;

[0037] 4) Heat the chlorinated paraffin to 45°C-60°C to reduce its viscosity and make it easy to stir;

[0038] 5) Mix the heated chlorinated paraffin with the material obtained in step 3), and stir thoroughly;

[0039] 6) Add regulator silicone oil and stir evenly; ...

Embodiment 2

[0043] Example 2 Preparation of adjustable fluid-solid coupling similar materials for model tests

[0044] The raw material composition is: 1 part of standard sand, 0.07 part of calcium carbonate, 0.07 part of barite powder, 0.07 part of cement, 0.12 part of water, 0.026 part of silicone oil, and 0.07 part of chlorinated paraffin.

[0045] The preparation method is:

[0046] 1) Weigh the standard sand, calcium carbonate, barite powder and cement in proportion;

[0047] 2) Mix the weighed standard sand, calcium carbonate, barite powder, cement and other four fine-grained materials and stir evenly;

[0048] 3) Weigh the mixing water, add the fine-grained material obtained in step 2) to mix, and stir thoroughly;

[0049] 4) Heat the chlorinated paraffin to 45°C-60°C to reduce its viscosity and make it easy to stir;

[0050] 5) Mix the heated chlorinated paraffin with the material obtained in step 3), and stir thoroughly;

[0051] 6) Add regulator silicone oil and stir evenly;...

Embodiment 3

[0054] Example 3 Preparation of adjustable fluid-solid coupling similar materials for model tests

[0055] The raw material composition is: 1 part of standard sand, 0.08 part of calcium carbonate, 0.07 part of barite powder, 0.06 part of cement, 0.12 part of water, 0.032 part of silicone oil, and 0.14 part of chlorinated paraffin.

[0056] The preparation method is:

[0057] 1) Weigh the standard sand, calcium carbonate, barite powder and cement in proportion;

[0058] 2) Mix the weighed standard sand, calcium carbonate, barite powder, cement and other four fine-grained materials and stir evenly;

[0059] 3) Weigh the mixing water, add the fine-grained material obtained in step 2) to mix, and stir thoroughly;

[0060] 4) Heat the chlorinated paraffin to 45°C-60°C to reduce its viscosity and make it easy to stir;

[0061] 5) Mix the heated chlorinated paraffin with the material obtained in step 3), and stir thoroughly;

[0062] 6) Add regulator silicone oil and stir evenly;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com