Pre-treatment and quantitative analysis method for rapid determination of content of cadmium element in rice

A technology for rapid determination and element content, applied in the preparation of test samples, measurement of color/spectral characteristics, etc., can solve the problems of difficult to guarantee the accuracy of results, cumbersome pre-processing process, difficult operation, etc., to achieve accuracy and repeatability. Good performance, saving pre-processing time, and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

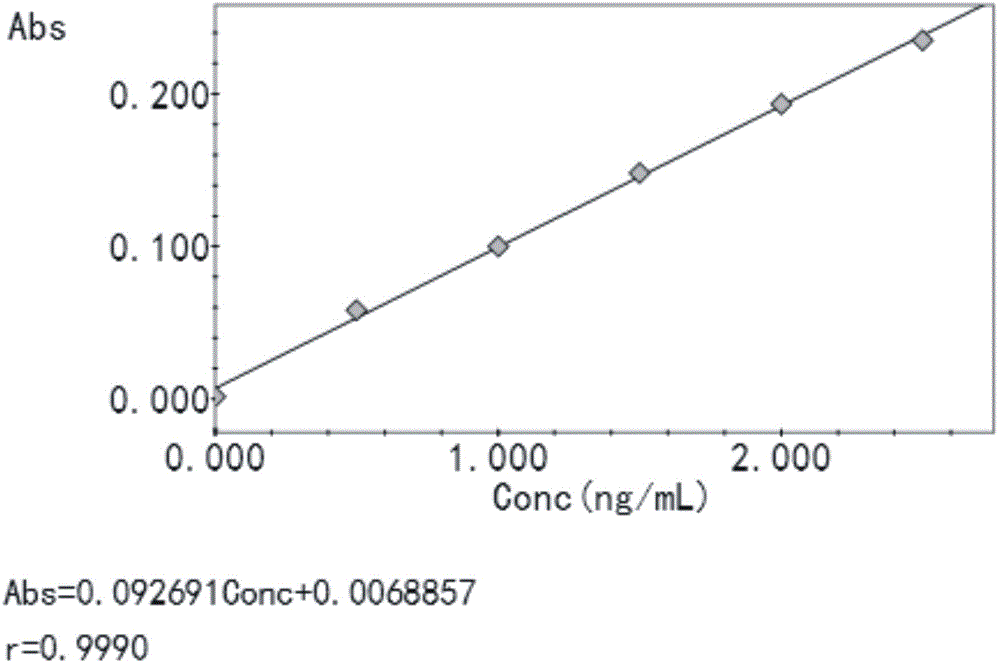

Embodiment 1

[0028] A pretreatment and quantitative analysis method for rapidly determining the content of cadmium in rice, comprising the following steps:

[0029] (1) Grind the husked brown rice with a mill so that all the brown rice flour can pass through a 40-mesh sieve, put it in a sealed bag, mix well, weigh 0.25 g of the sample in a 25 mL colorimetric tube, and weigh 6 parts Parallel samples, numbers are A~F;

[0030] (2) Weigh 0.4 g of agar powder into a 1 L beaker, add slightly less than 500 mL of ultrapure water, heat to dissolve the agar, let it stand to cool, add water to 500 mL, and prepare a 0.8 g / L agar solution for later use ;

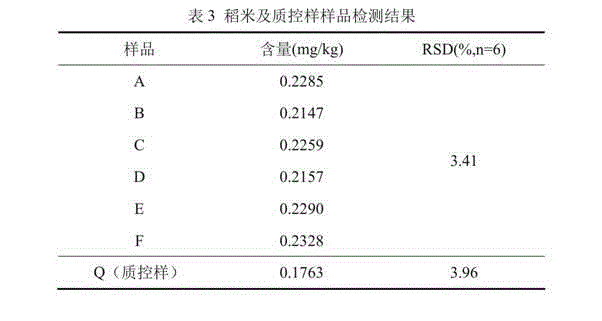

[0031] (3) Dilute samples A~F to 25 mL with the agar solution obtained in step (2) to obtain the suspensions of samples A~F respectively. Take 0.6 mL of the suspensions of samples A~F respectively in 2 mL sample cups , dilute 2.5 times with 1% dilute nitric acid to obtain the rice samples A to F to be tested; process the quality control sample GBW...

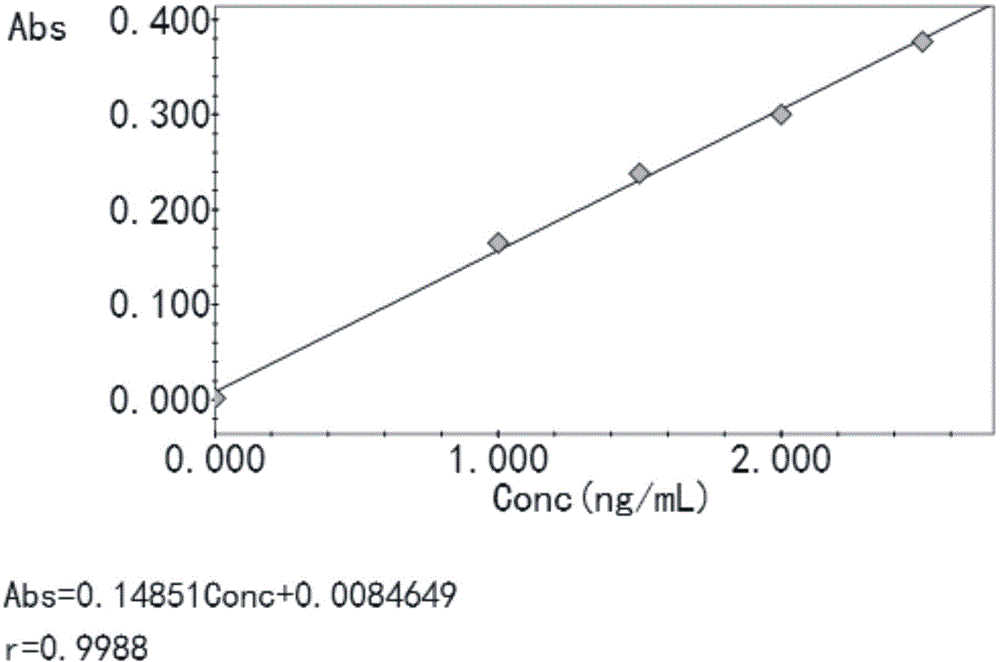

Embodiment 2

[0041] A pretreatment and quantitative analysis method for rapidly determining the content of cadmium in rice, comprising the following steps:

[0042] (1) Grind the husked brown rice with a mill so that all the brown rice flour can pass through a 40-mesh sieve, put it in a sealed bag, mix well, weigh 1.0 g of the sample in a 25 mL colorimetric tube, and weigh 6 parts Parallel samples, numbers are A~F;

[0043] (2) Weigh 0.75 g of agar powder into a 1 L beaker, add slightly less than 500 mL of ultrapure water, heat to dissolve the agar, let it cool down, add water to 500 mL, and prepare a 1.5 g / L agar solution for later use ;

[0044] (3) Dilute samples A~F to 25 mL with the agar solution obtained in step (2) to obtain suspensions of samples A~F respectively; take 0.6 mL of suspensions of samples A~F respectively in 2 mL sample cups , dilute 2.5 times with 1% dilute nitric acid to obtain the rice samples A to F to be tested; process the quality control sample GBW10045 in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com