A pump light multi-pass transmission system and disk solid-state laser

A transmission system and pump light technology, applied in the laser field, can solve the problems of limited pump times, low system conversion efficiency, low pump light absorption efficiency, etc., to reduce thermal distortion, design difficulty, and pump spot distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

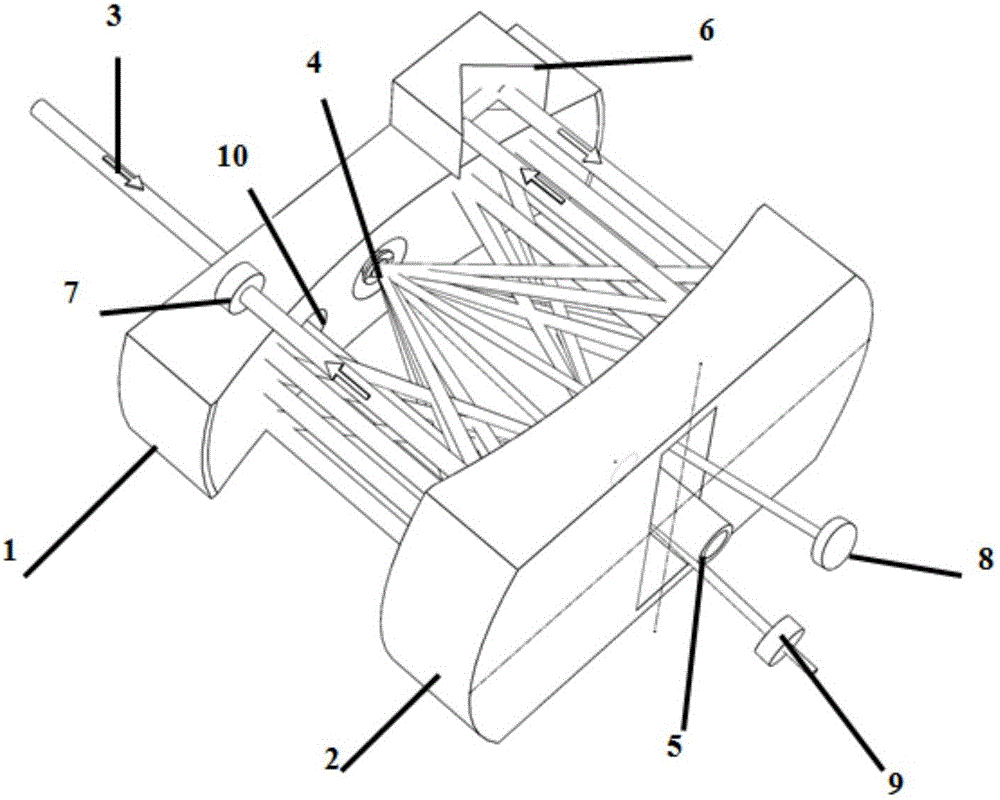

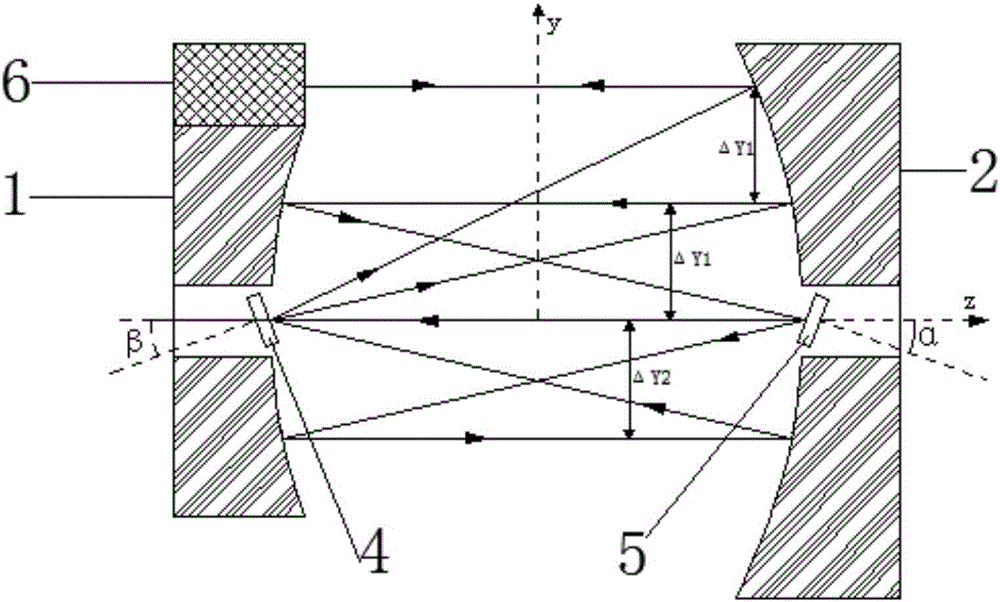

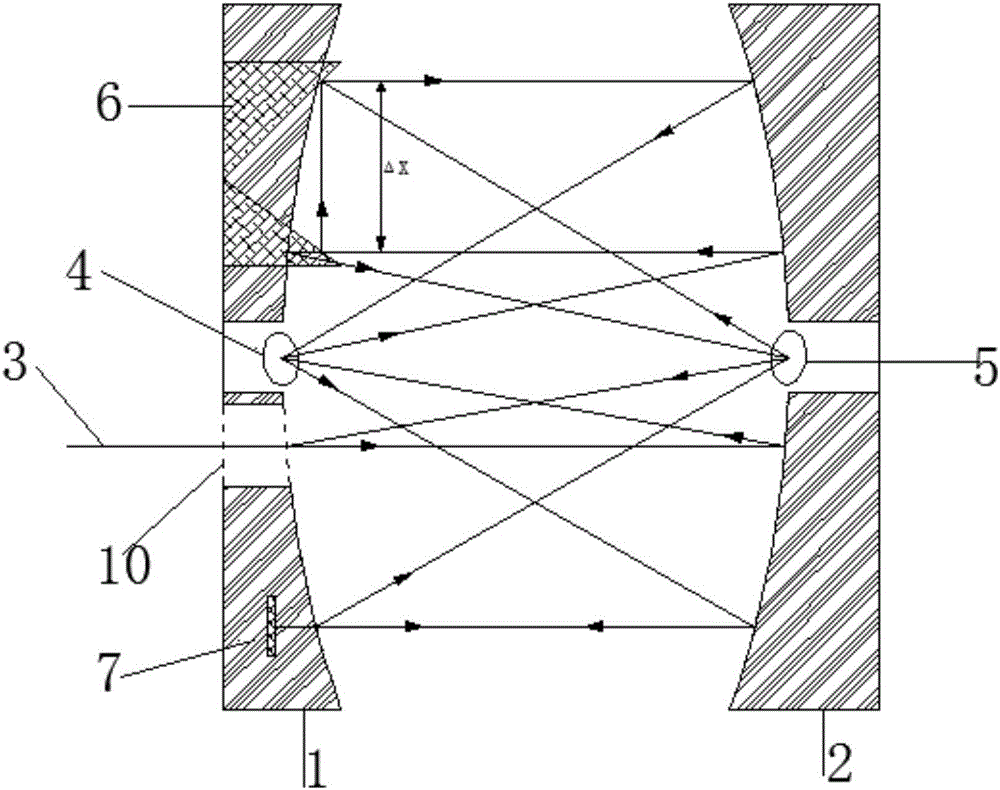

[0044] Pump light multi-pass transmission systems, such as figure 1 shown. The first parabolic mirror 1 and the second parabolic mirror 2 are placed in a conjugate, that is, the focus of the first parabolic mirror 1 is at the center of the second parabolic mirror 2, and the focus of the second parabolic mirror 2 is at the first at the center of the parabolic mirror 1. The first parabolic mirror is provided with a pump light incident hole 10 . The height of the first parabolic mirror 1 is lower than that of the second parabolic mirror 2 , and the height difference is used to place the right-angle total reflection mirror 6 and the pump light total reflection mirror 7 . The right-angle mirror 6 and the pump light total reflection mirror 7 are placed on both sides above the first parabolic mirror 1, and the right-angle surface of the right-angle mirror 6 faces the second parabolic mirror, which is used to realize the lateral shift of the incident light. 180 degree reflection. ...

Embodiment 2

[0051] Pump light multi-pass transmission systems, such as Figure 5 shown. The first parabolic mirror 1 and the second parabolic mirror 2 are placed in a conjugate, that is, the focus of the first parabolic mirror 1 is at the center of the second parabolic mirror 2, and the focus of the second parabolic mirror 2 is at the first at the center of the parabolic mirror 1. The first parabolic mirror is provided with a pump light incident hole 10 . The height of the first parabolic mirror 1 is lower than that of the second parabolic mirror 2 , and the height difference is used to place two right-angle reflecting prisms 6 . Two right-angle mirrors 6 are placed on both sides above the first parabolic mirror 1 , and the right-angle surfaces of the right-angle mirrors face the second parabolic mirror to achieve 180-degree reflection after lateral shift of incident light. The center of the first and second parabolic mirrors needs to be hollowed out. The center of the first parabolic ...

Embodiment 3

[0058] Pump light multi-pass transmission systems, such as Figure 9 shown. The first parabolic mirror 1 and the second parabolic mirror 2 are placed in a conjugate, that is, the focus of the first parabolic mirror 1 is at the center of the second parabolic mirror 2, and the focus of the second parabolic mirror 2 is at the first at the center of the parabolic mirror 1. On the first parabolic reflector, pump light incident holes 10 are respectively provided on both sides. The height of the first parabolic mirror 1 is lower than that of the second parabolic mirror 2 , and the height difference is used to place two right-angle mirrors 6 . Two right-angle reflecting prisms 6 are placed on both sides above the first parabolic reflecting mirror 1 , and the right-angle surfaces of the right-angle reflecting mirror face the second parabolic reflecting mirror, so as to realize 180-degree reflection after lateral shift of incident light. The center of the first and second parabolic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com