Device for the continuous treatment of solids in a fluidised bed apparatus

A vortex layer and solid technology, applied in lighting and heating equipment, chemical/physical processes, chemical instruments and methods, etc., can solve the problems of large residence time distribution spectrum, regardless of continuous processing, etc., to achieve simple manufacturing, save space, Latency/distortion small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

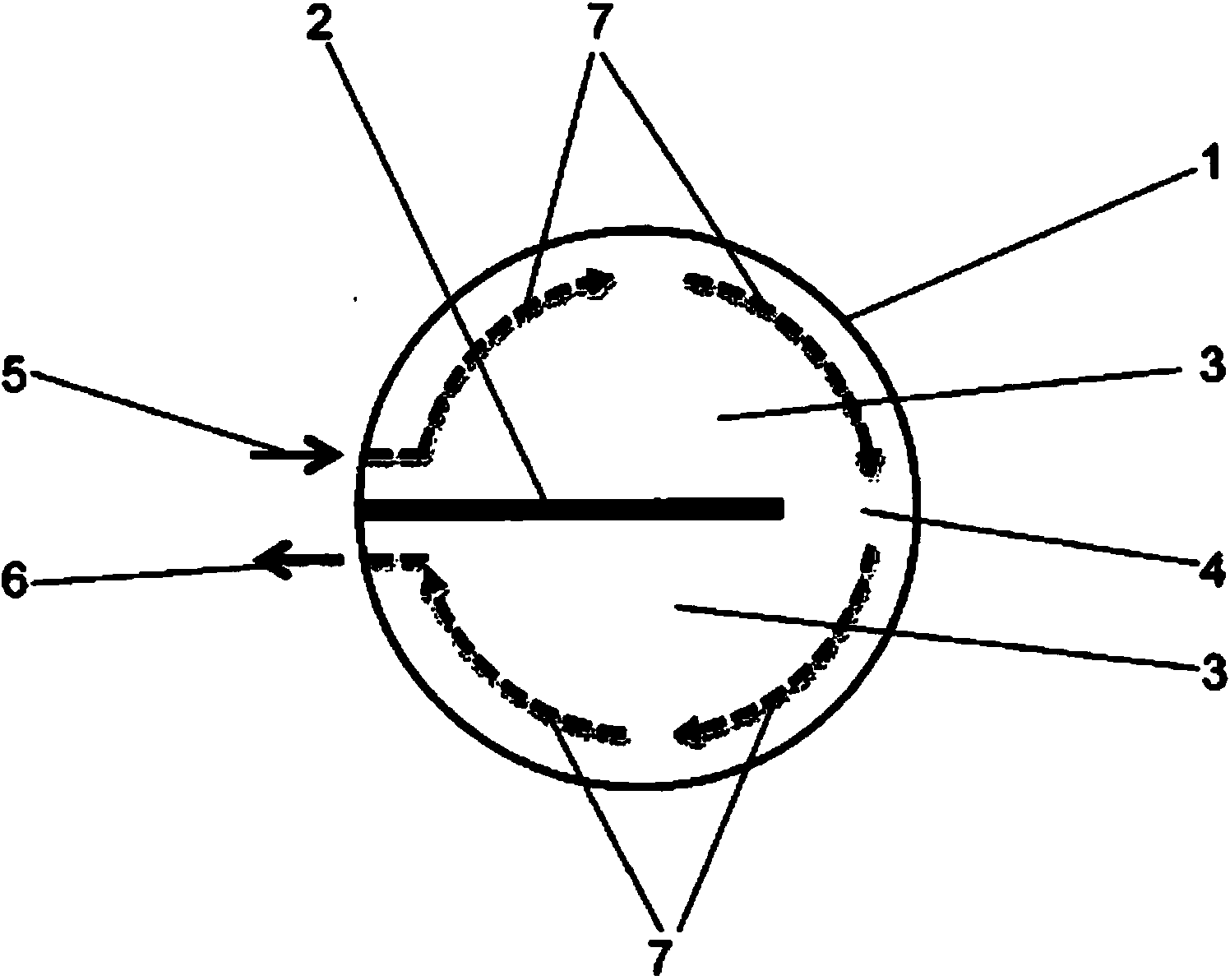

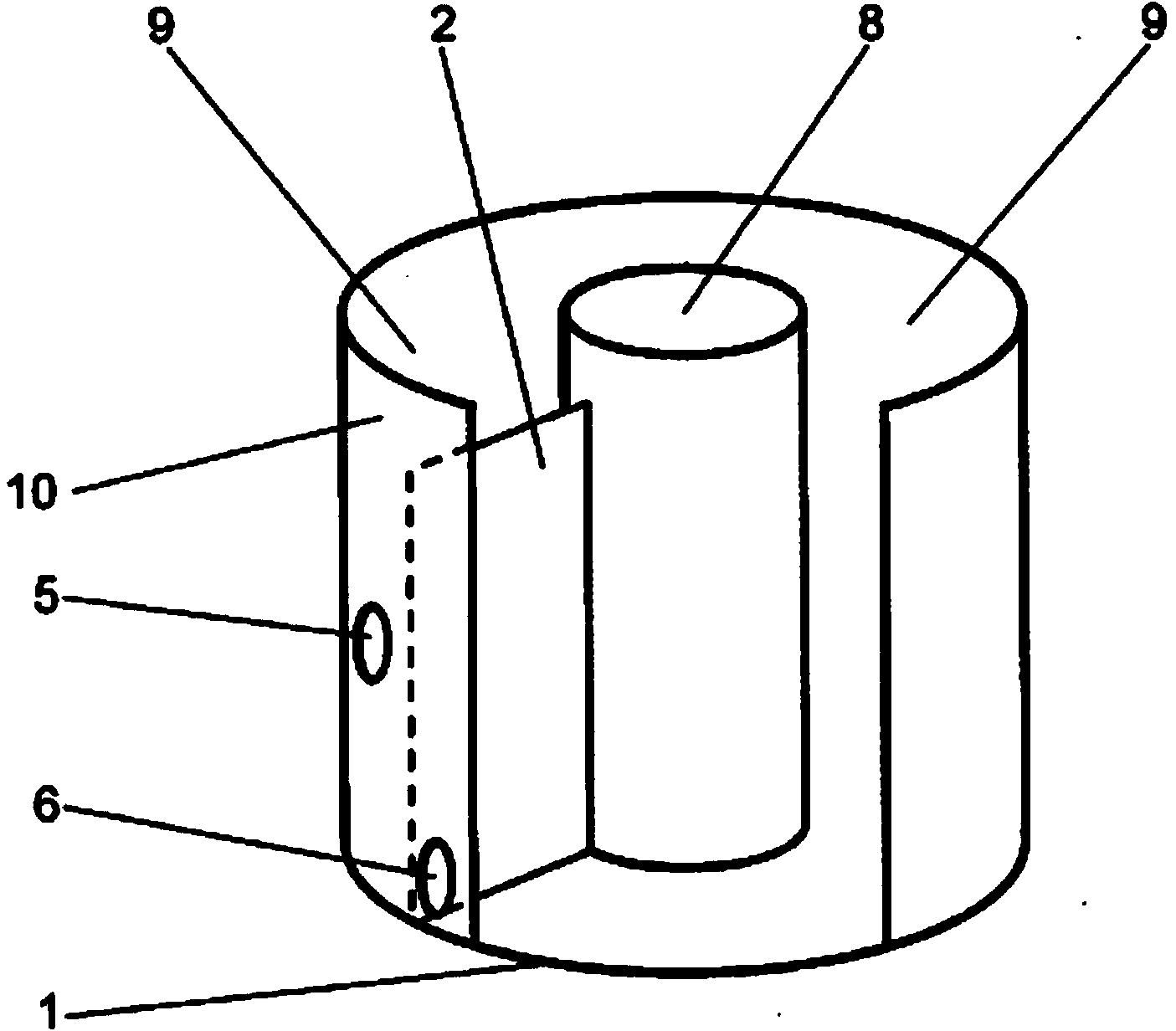

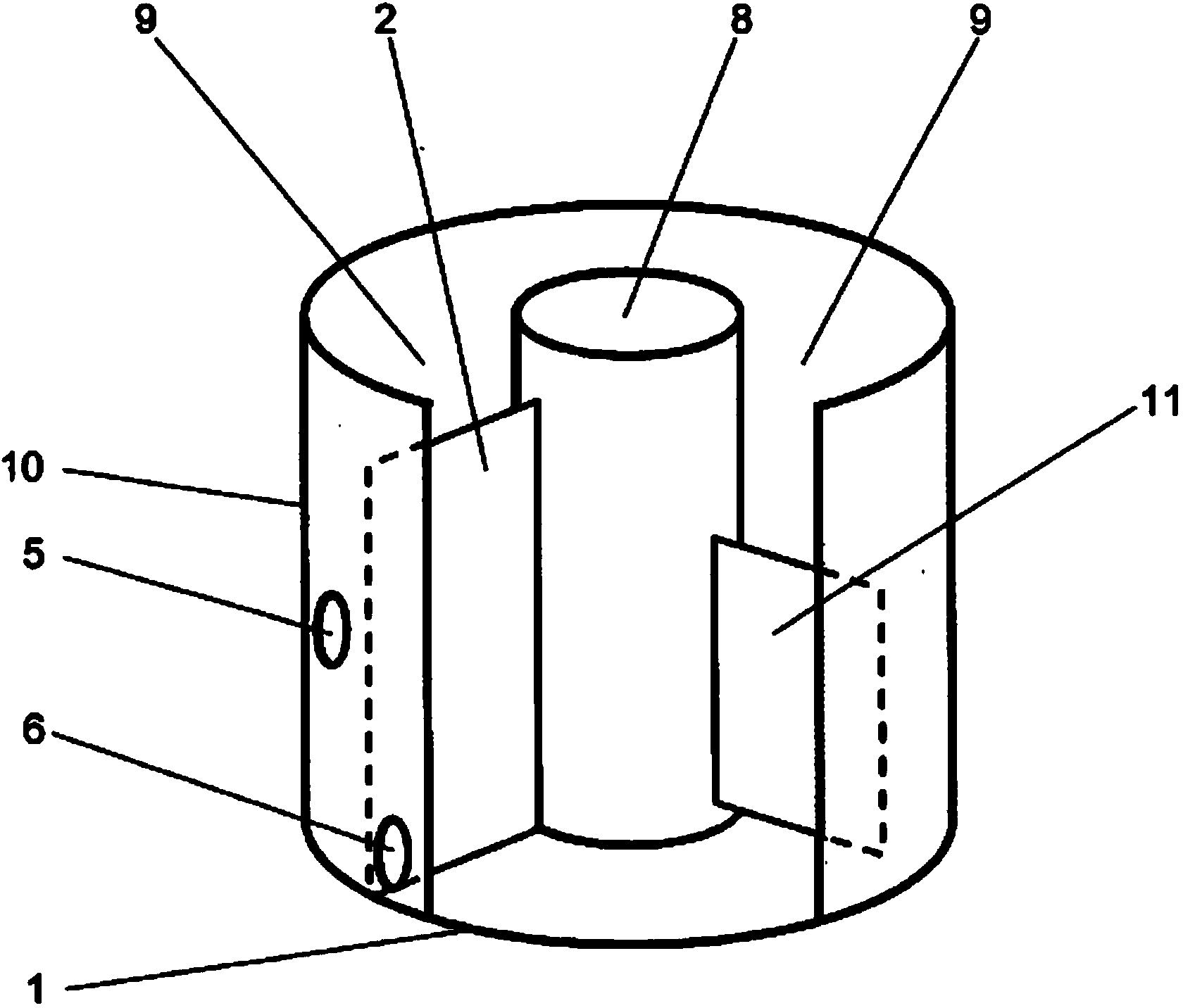

[0024] figure 1 The principle of the device according to the invention is shown, wherein only the circumference of the circular inflow bottom 1 is shown here, the inflow bottom 1 having a partition wall 2 vertically rising from it, the partition wall 2 extending from its circumference It extends up to above the center of the inflow bottom 1 , so that the treatment chamber 3 is divided into two regions of equal size, which are connected to each other at the free end of the partition wall 2 by a narrow region 4 . Solids to be processed enter the unit through an input port at the figure 1 Indicated by the arrow 5 pointing to the bottom 1 of the inflow. Treated solids are withdrawn from the device through the outlet, indicated by the arrow 6 pointing away from the bottom 1 of the inflow. Reference numeral 7 designates the flow path through which the solids travel between the inlet 5 and the outlet 6 . By providing the inlet opening 5 and the outlet opening 6, the solids move ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com