System and method for utilizing lng for fuel to liquefy lpg boil-off gas

A technology for evaporating gas and fuel supply systems, applied in the direction of gas processing/storage purposes, liquefaction, refrigeration and liquefaction, etc., can solve the problem of not describing the evaporation and reliquefaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

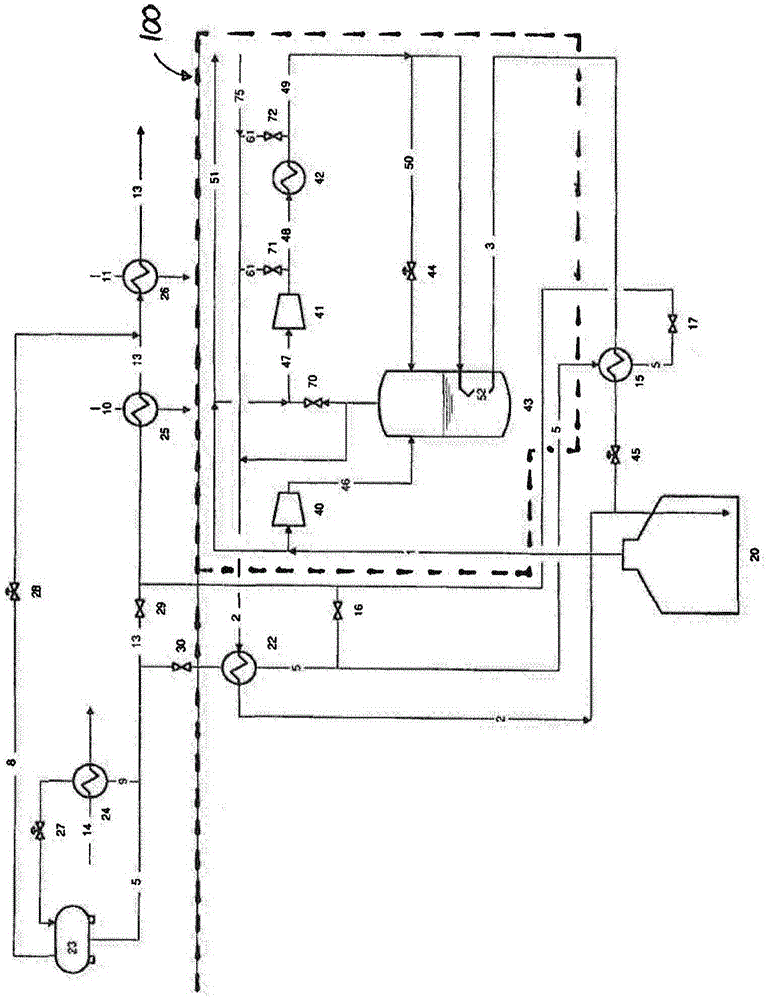

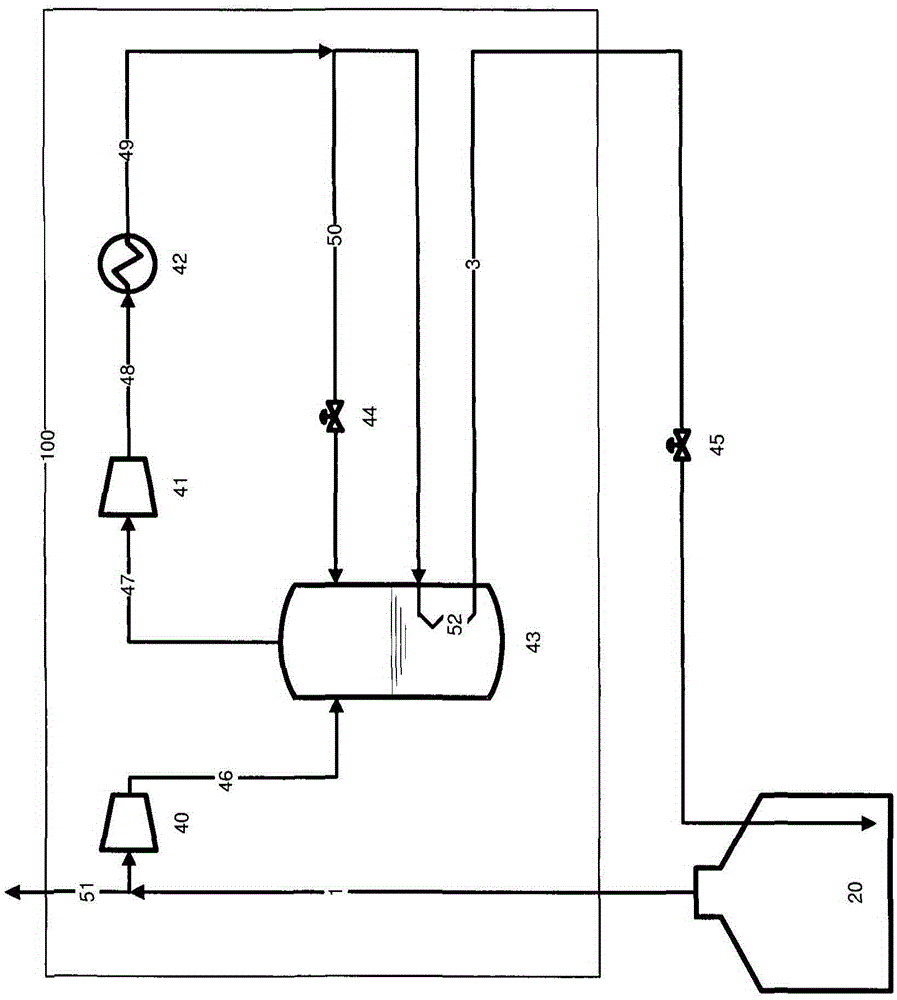

Embodiment Construction

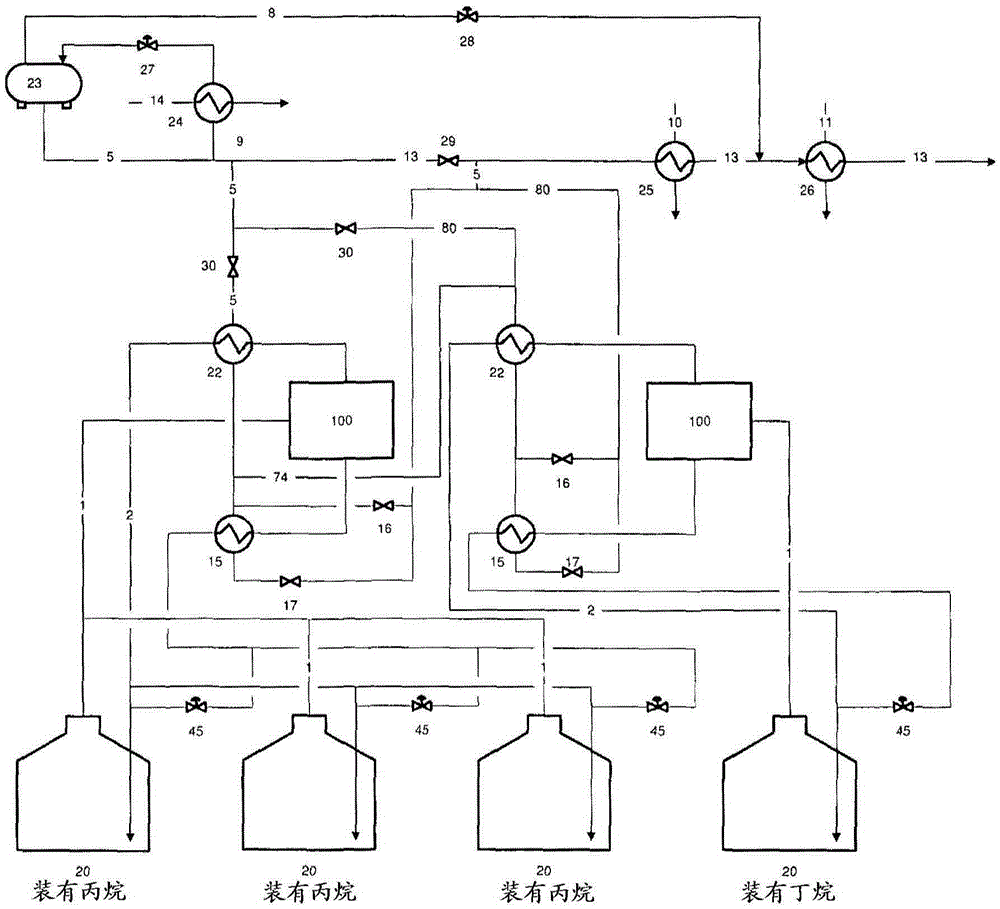

[0028] LPG is to be understood as a range of different varieties or products of petroleum gas stored and transported as a liquid cargo. Of the various petroleum gases, propane and butane are prime examples; propane typically includes ethane in any concentration from 0% to 5% by volume; butane in propane can be present in any concentration from 0% to 20% by volume . This mixture consisting mainly of propane (typically 70% to 98% by volume) is called commercial propane, and is hereinafter referred to as propane.

[0029] Butane can be any mixture of n-butane and isobutane with possible fractions of unsaturated hydrocarbons and is referred to hereinafter as butane.

[0030] In addition to propane and butane, LPG shall at least include the following varieties:

[0031] ammonia,

[0032] Butadiene,

[0033] butane-propane mixture (any mixture),

[0034] Butene,

[0035] ether,

[0036] Propylene,

[0037] vinyl chloride.

[0038] LPG stored and transported at sub-ambient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com