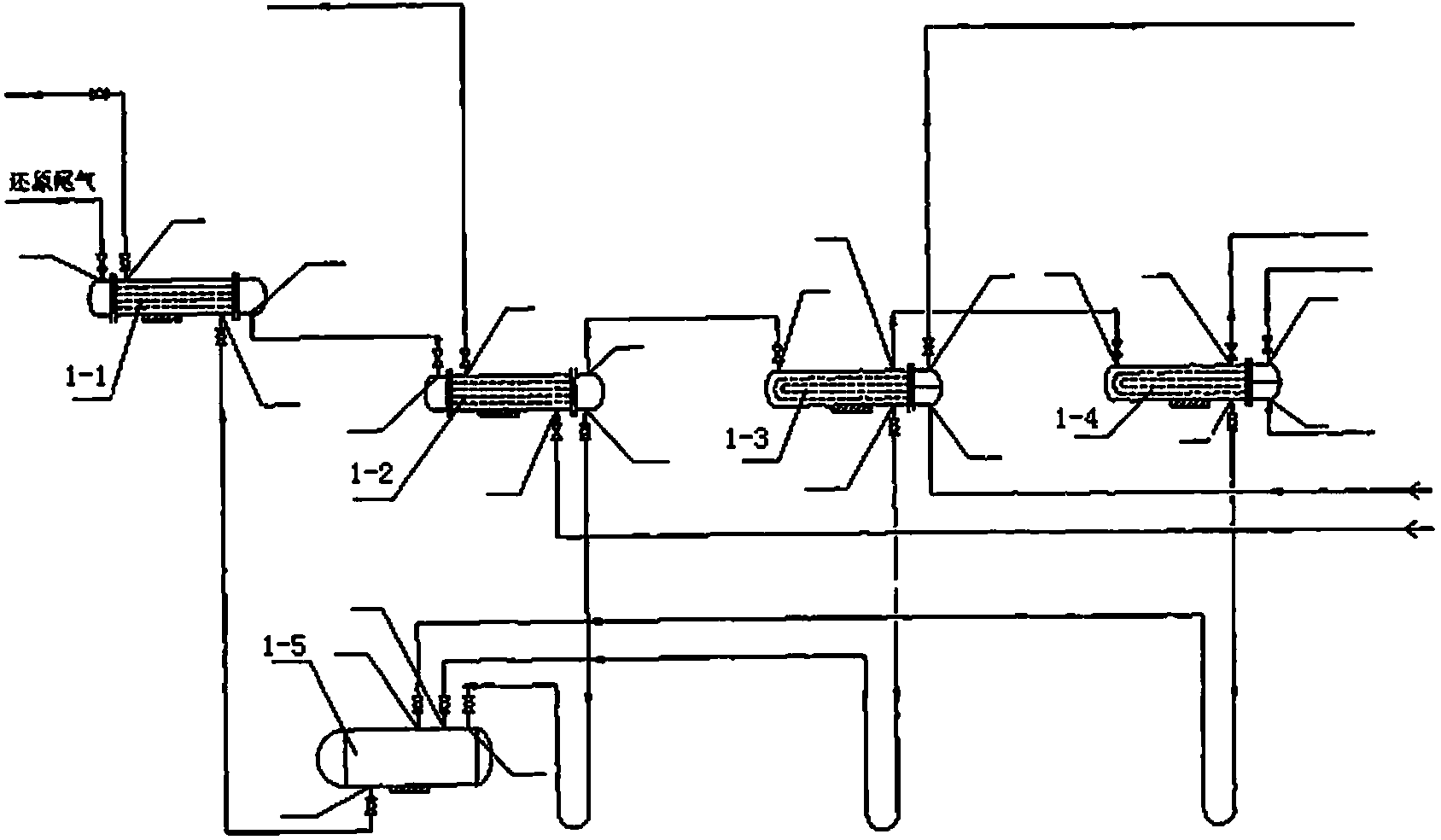

Improved tail gas condensation separator in polysilicon production

A technology of condensation separation and polysilicon, which is applied in the field of reduction tail gas recovery, can solve the problem of high energy consumption, and achieve the effect of saving equipment investment and operating costs, and saving equipment investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

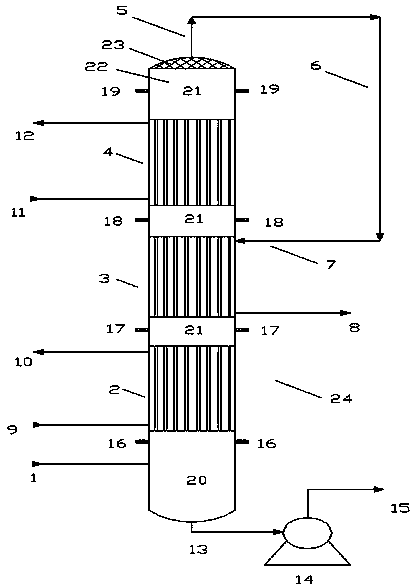

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0035] In this embodiment, the structure of a device used for the improved polysilicon production tail gas condensation and separation method is as follows figure 2As shown, the reduction tail gas at 120°C is left in the reduction tail gas liquid collector (20) through the reduction tail gas inlet (1), and is initially separated under the action of gravity, and the separated chlorosilane liquid enters the reduction tail gas liquid collector (20); the gas enters the circulating water heat exchanger (2) for heat exchange, the outlet temperature of the circulating water heat exchanger (2) is 30°C to 50°C, and the condensed vapor-liquid mixture enters the reduction tail gas and then In the distributor (21), further vapor-liquid separation is carried out under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com