Broaching tool for machining small-caliber gun body tube inner hole rifling

A gun barrel and small-caliber technology, applied in the field of mechanical processing, can solve the problems of large aspect ratio, large inner hole diameter, high cost of investment in electrolytic processing equipment, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

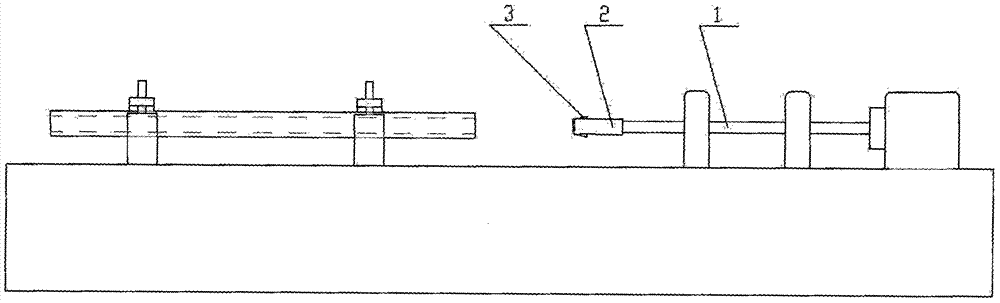

[0027] Such as figure 1 As shown, a broaching tool for processing small-caliber artillery barrel inner hole rifling according to the present invention comprises a wire drawing tool holder 1, a wire drawing tool holder 2, and a wire drawing tool head 3. The wire drawing tool holder is fixed on the machine tool through a fixed pin shaft, and The pull rod is connected to the machine tool through threads.

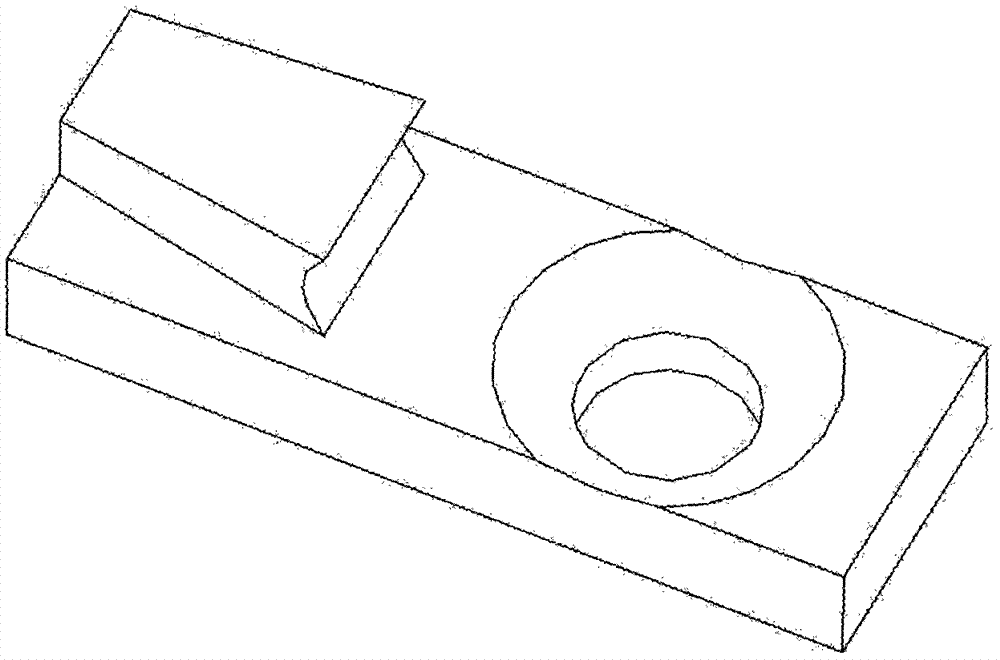

[0028] Such as figure 2 As shown, wherein the wire drawing cutter head 3 includes a knife holder and a blade, the knife holder is a flat plate structure, and the upper surface of the knife holder is processed with a blade matching the rifling size;

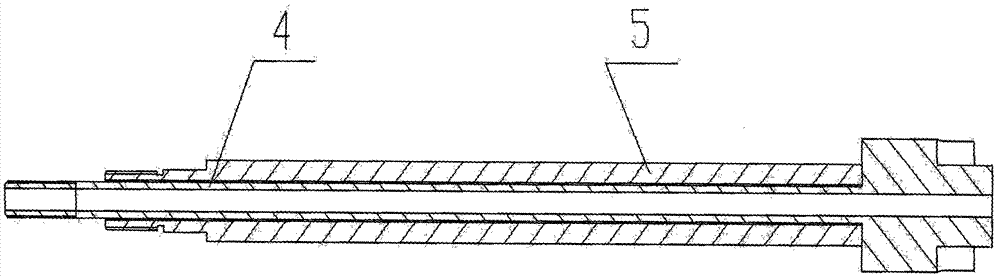

[0029] Such as image 3 As shown, the wire-drawing knife bar 1 includes a knife bar body 5 and a pull rod 4, the center of the pull bar 4 has a through hole, and the outer wall of the front end of the pull bar 4 is processed with external threads, and the inner diameter of the knife bar body 5 matches the outer diameter of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com