Method for processing spiral bevel gears on general six-axle numerically-controlled machine tool

A technology of spiral bevel gears and CNC machine tools, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of low machine tool processing flexibility, expensive software, and low machine tool utilization, and achieve The effect of reducing processing costs, good economic benefits, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

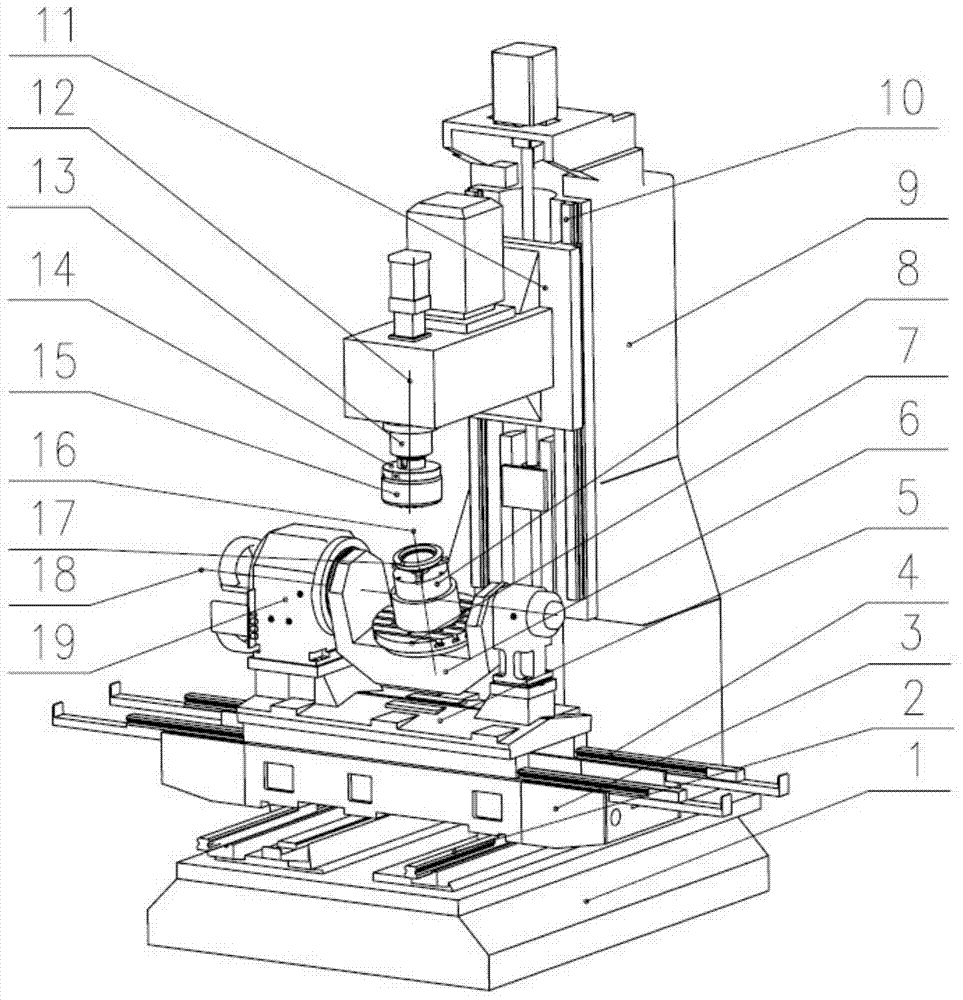

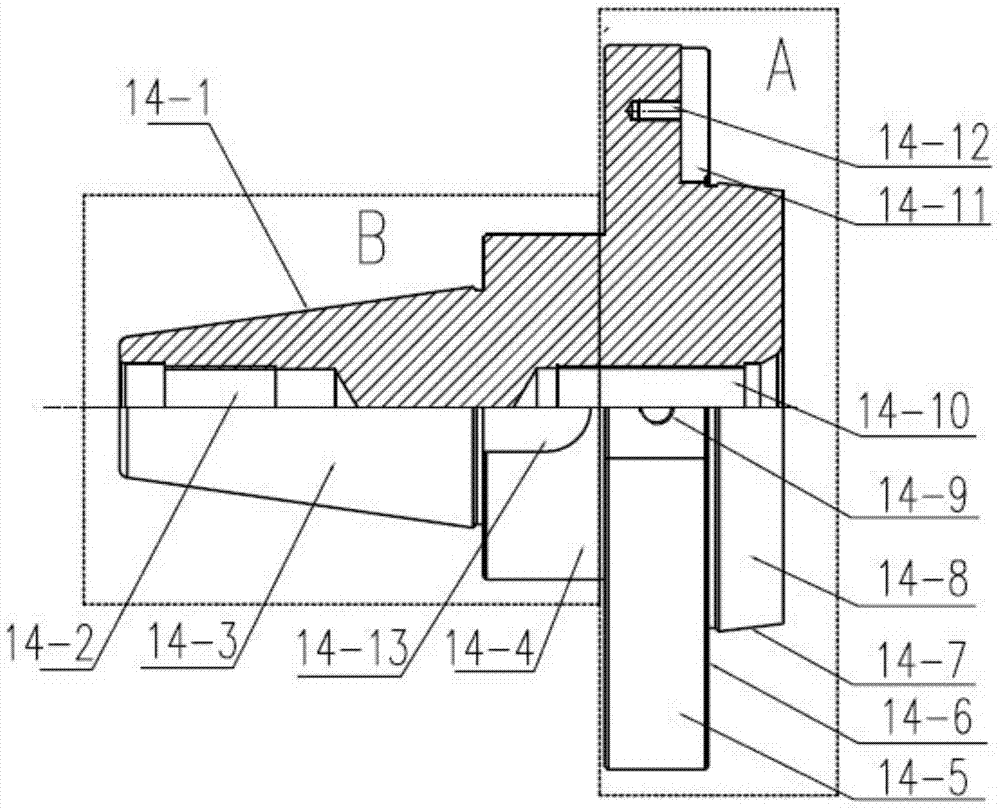

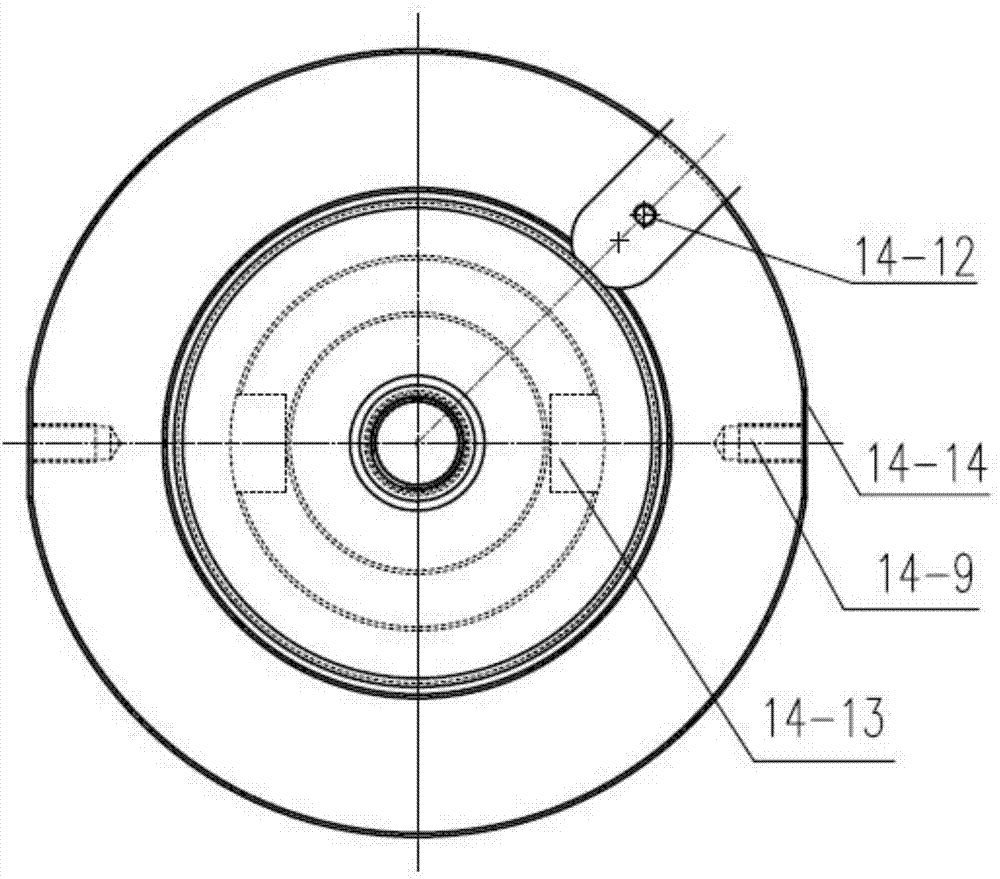

[0026] see Figure 1 to Figure 4 , a method for processing spiral bevel gears on a general-purpose six-axis numerical control machine tool, the general-purpose six-axis numerical control machine tool includes a bed 1, an X-direction linear guide 4, a Y-direction linear guide 2, a Z-direction linear guide 10, a first drive mechanism and the second drive mechanism.

[0027] The Y-direction linear guide 2 is fixed on the bed 1, the Y-axis slide 3 is installed on the Y-direction linear guide 2, and the X-direction linear guide 4 is fixed on the Y-axis slide 3. An X-axis bed saddle 5 is installed on the X-direction linear guide rail 4 .

[0028] A column 9 is arranged behind the bed 1, and a Z-direction linear guide rail 10 is installed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com