Active covering method for in-situ remediation of sediments

An in-situ restoration and sediment technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of weak complex pollution treatment ability, unfriendly environment, and reduction of effective storage capacity, etc. To achieve the effect of reducing water storage capacity, low cost and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

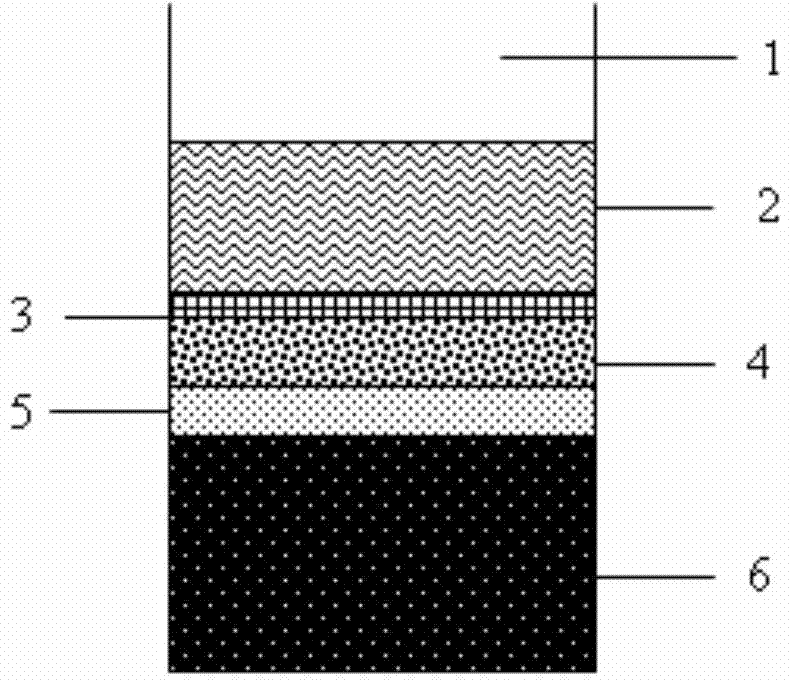

[0021] Embodiment 1: The active covering method for in-situ restoration of deposits is as follows:

[0022] 1. Selection of in-situ covering materials: selection of ferrihydrite, calcite, geotextile and local river sand;

[0023] 2. Pretreatment of in-situ covering materials: Ferrihydrite is crushed and passed through a 200-mesh sieve, washed for later use; calcite is crushed and passed through a 40-mesh sieve, washed for later use; geotextiles are washed for later use; local river sand is washed for later use ;

[0024] Three, the ferrihydrite powder pretreated in step 2 is evenly sprinkled into the water body and covered on the sediment at the bottom of the water body, and the average thickness of the ferrihydrite powder layer covered on the sediment is 5mm;

[0025] Four, step 2 pretreated calcite sand is evenly sprinkled into the water body and covered on the ferrihydrite powder layer, and the average thickness of the calcite sand layer covered on the ferrihydrite powder ...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the geotextile described in step 1 is polyester non-woven fabric. Others are the same as in the first embodiment.

[0029] Adopt following experiment verification effect of the present invention:

[0030] Take the sediment cores of a representative temperate eutrophic shallow lake in southeastern Australia, use the method of specific embodiment 1 to cover 3 sediment cores as the treatment group, and take 3 untreated sediment cores as the control group, and continuously The content of total phosphorus and total nitrogen in the water body was monitored in real time for 15 days.

[0031] The results showed that the total phosphorus content of the water body in the treatment group has been gradually decreasing, from (0.23±0.06) mg / L to (0.06±0.03) mg / L, while the total phosphorus content of the control group has been fluctuating, with an average content of (0.23±0.05)mg / L. After calculation, the total phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com