Fire-proof sealing material and preparation method thereof

A technology of fireproof sealing and coating, which is applied in the direction of fireproof coatings and coatings, which can solve the problems of affecting the service life and achieve the effects of long service life, simple preparation process and good hole size compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Apply 1.5mm thick expandable graphite coating on one side of the 5mm thick EVA foam board at one time to form an expandable graphite coating layer. After 24 hours at room temperature, coat the other side, and the other side is coated with 1.5mm thick expandable graphite coating. The graphite coating also forms an expandable graphite coating layer, and the finished product of the firestopping material is 8mm thick in total. The expandable graphite coating layer can also be coated to the required thickness multiple times, and the surface smoothness of multiple coatings is better than that of one-time coating. The finished product of the fireproof sealing material can be stretched, bent, compressed, punched and cut.

Embodiment 2

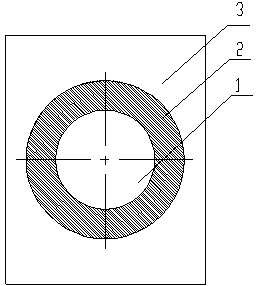

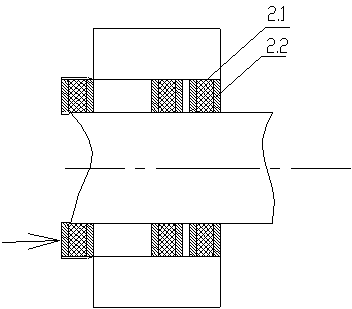

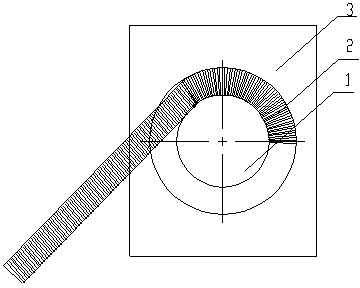

[0031] Die a 5mm thick EVA foam board into a sheet with an outer diameter of 120mm and an inner diameter of 100mm, put the sheet into a mold and coat the expandable graphite coating on its four sides to form an expandable graphite coating layer, and obtain an outer diameter of 123mm and an inner diameter of 97mm , 8mm thick fireproof plugging material 2 finished product, the finished fireproof plugging material is set outside the pipe with an outer diameter of 100mm (the penetrating object 1, the penetrating object 1 can be a steel pipe or a cable, etc.), and the hole with an inner diameter of 118mm~123mm ( Formed between the penetrating object 1 and the penetrating object 3, the penetrating object can be a pinch-off wall or floor, etc.) for sealing, such as figure 1 and figure 2 shown.

Embodiment 3

[0033] The finished fireproof sealing material made in Example 1 is punched into a sheet with a thickness of 8 mm, an outer diameter of 123 mm, and an inner diameter of 98 mm. The hole is sealed, such as figure 1 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com