Epoxy resin sealing adhesive

A sealing adhesive and epoxy resin technology, which is applied in the direction of epoxy resin glue, adhesives, adhesive additives, etc., can solve the problems of poor processability, unsatisfactory use and performance, poor curing comprehensive performance, etc. Excellent curing performance and easy production

Inactive Publication Date: 2014-03-05

ANHUI KANGRUIXIN ELECTRONICS TECH

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, the epoxy potting adhesives in the prior art are generally two-component and can be cured at room temperature, but the use and performance are not ideal, the manufacturability is poor, and the curing comprehensive performance is poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

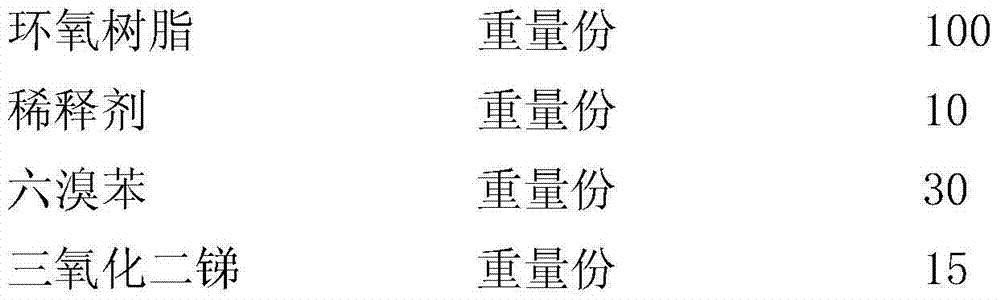

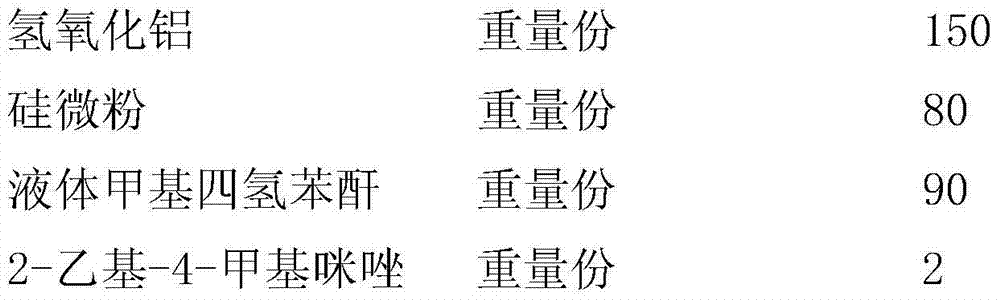

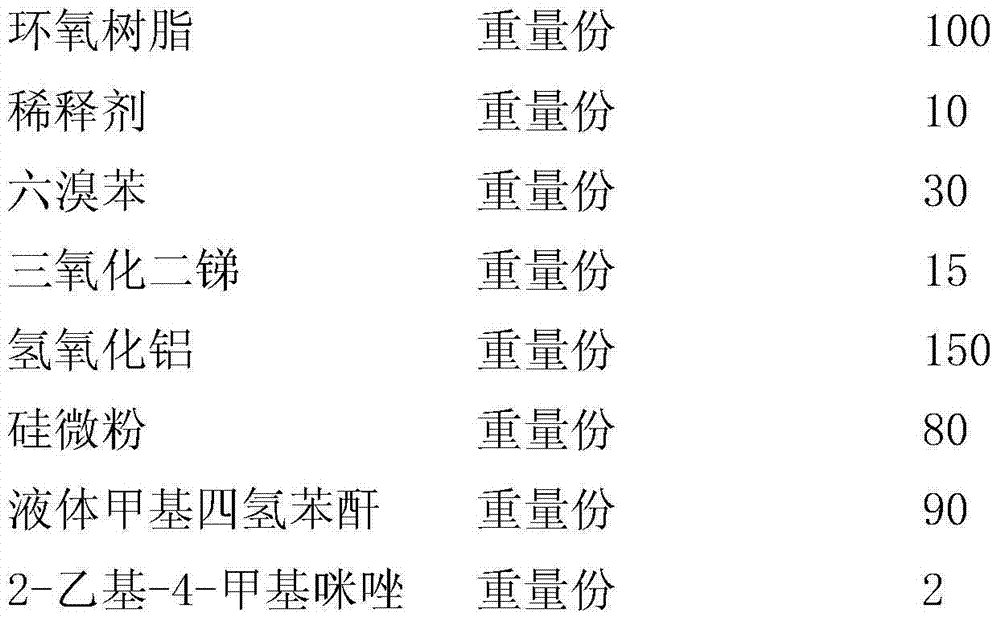

[0020] An epoxy resin sealing adhesive comprising the following components:

[0021]

[0022] The above ingredients are cured by heating.

[0023] The temperature during curing was 150° C., and the curing time was 2 hours.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention provides an epoxy resin sealing adhesive, relating to the technical field of adhesives. The adhesive is characterized by comprising the following components in parts by weight: 100 parts of epoxy resin, 10 parts of diluter, 30 parts of hexabromo-benzene, 15 parts of antimony trioxide, 150 parts of aluminum hydroxide, 80 parts of silicon micropowder, 90 parts of liquid methyl tetrahydrophthalic anhydride and 2 parts of 2-ethyl-4-methylimidazole. The components are cured by heating. The adhesive is simple in formula and convenient to manufacture, and has the advantages of excellent curing property and favorable technical properties.

Description

Technical field: [0001] The invention relates to the technical field of adhesives, in particular to an epoxy resin sealing adhesive. Background technique: [0002] Since the 1950s, with the development of the electronics industry towards miniaturization, light weight, and precision, epoxy potting adhesives have been widely used in the electronic component manufacturing industry and have become important insulating materials for the electronics industry. . There are some requirements for epoxy potting adhesives as follows. [0003] ① Low viscosity, good impregnation, can fill between components and wiring. [0004] ②The application period is long, suitable for the production operation of the automatic assembly line industry. [0005] ③ During the potting and curing process, the inorganic filler in the potting compound is not easy to settle and will not be stratified. [0006] ④The curing heat release is low and the shrinkage rate is small. [0007] ⑤ The cured product ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C09J163/00C09J163/02C09J11/04C09J11/06C09K3/10

Inventor 朱保瑞郝志成翟彬

Owner ANHUI KANGRUIXIN ELECTRONICS TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap