Pre-tensioning - pre-twisting full-bridge 2D electro-hydraulic proportional directional valve

一种电液比例、全桥式的技术,应用在阀细节、多通阀、阀装置等方向,能够解决无法正常工作导控级泄漏流量、导控型电液比例阀流量大、卡滞导控级油路等问题,达到克服不利影响、结构简单、实现比例控制功能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

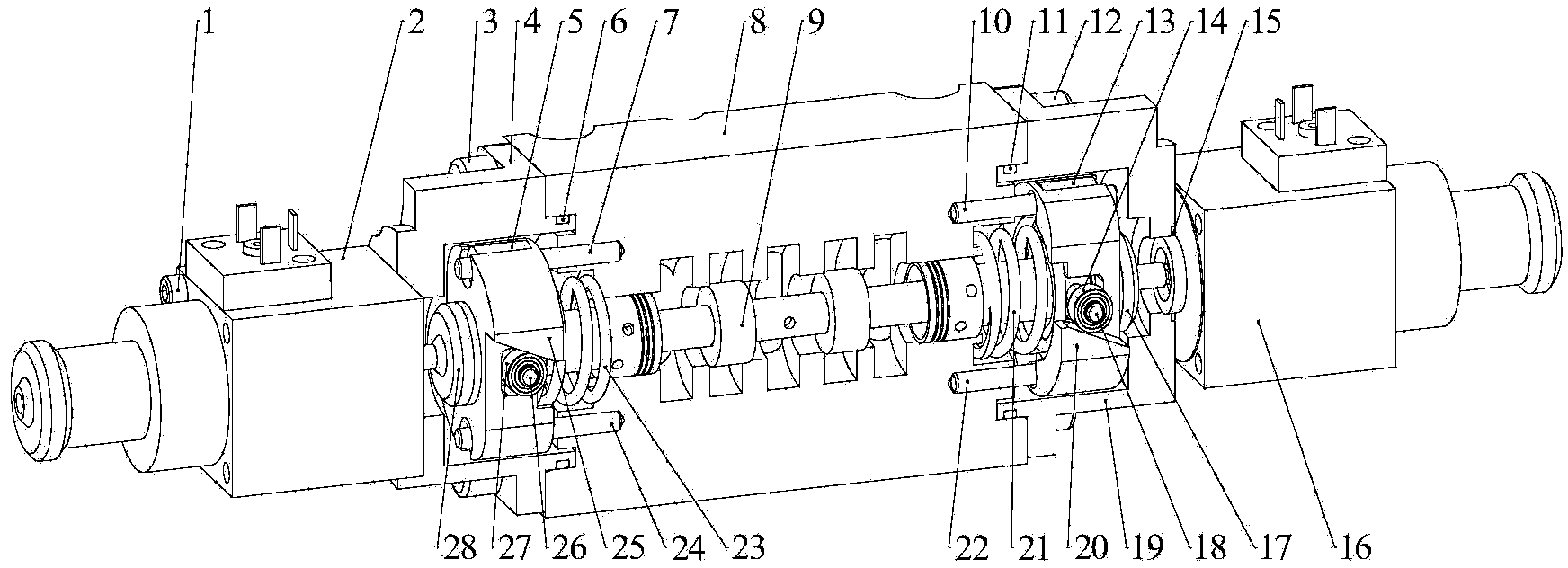

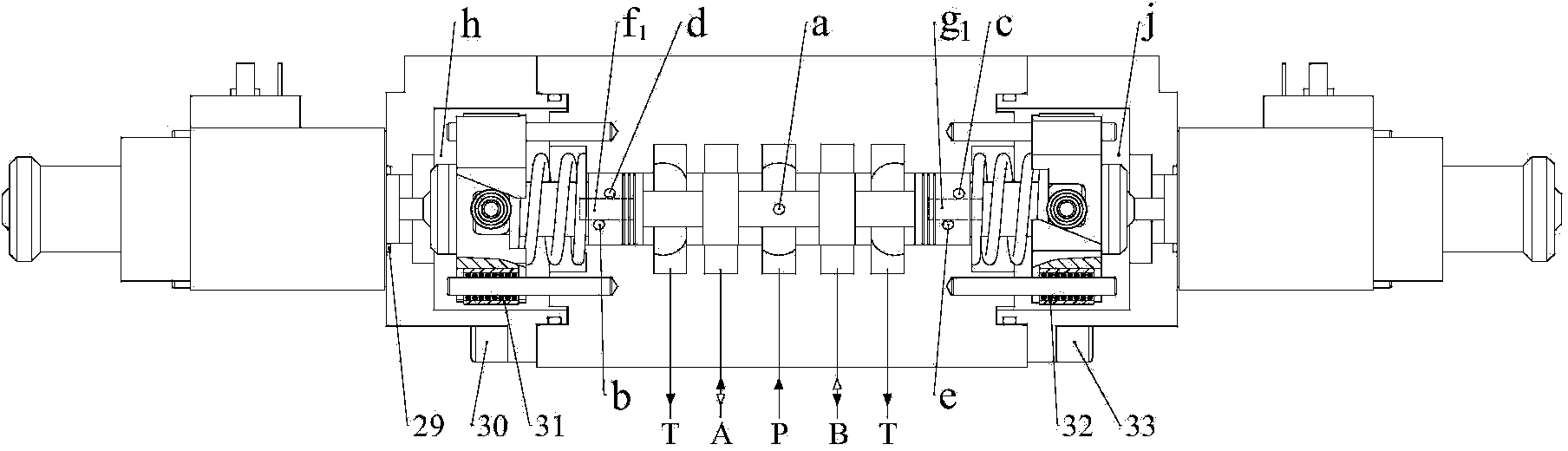

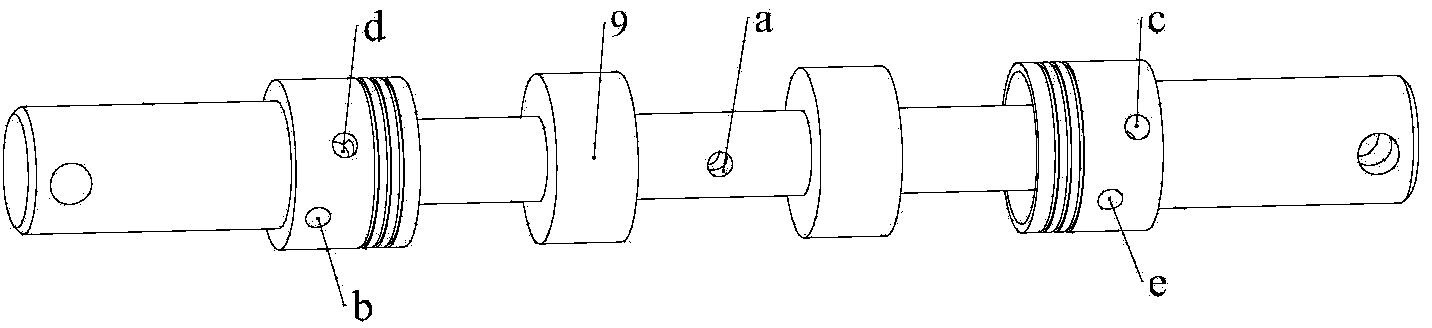

[0036] refer to Figure 1 to Figure 10 , a pre-tensioned-pre-twisted full bridge 2D electro-hydraulic proportional reversing valve includes screws 1, 3, 12, 30, 33, linear electro-mechanical converters 2, 16, end covers 4, 19, linear bearings 5 , 13, 31, 32, cylindrical compression spring 21, 23, O-ring 6, 11, 15, 29, pin 7, 10, 22, 24, valve body 8, valve core 9, rolling bearing 14, 27, 36, 38, top cover 17,28, bearing pin 18,26, sliding wedge 20,25, tightening screw 34, steel ball 35, sleeve 37,39.

[0037] The pre-tension-pre-twist type full-bridge 2D electro-hydraulic proportional reversing valve is composed of a 2D valve, linear electro-mechanical converters 2 and 16 at both ends, and a compression-torsion coupling between them.

[0038] Pre-tension-pre-twisted full-bridge 2D electro-hydraulic proportional reversing valve, including a 2D valve composed of a valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com