Sheet array calorimeter for energy deposition depth measurement of intense current electron beam

A high-current electron beam and energy deposition technology, which is applied in the field of interaction between electron beam and matter, can solve the problems of poor time response of graphite sheet array calorimeter and high mechanical performance requirements of sheet materials, and achieve the effect of solving slow response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

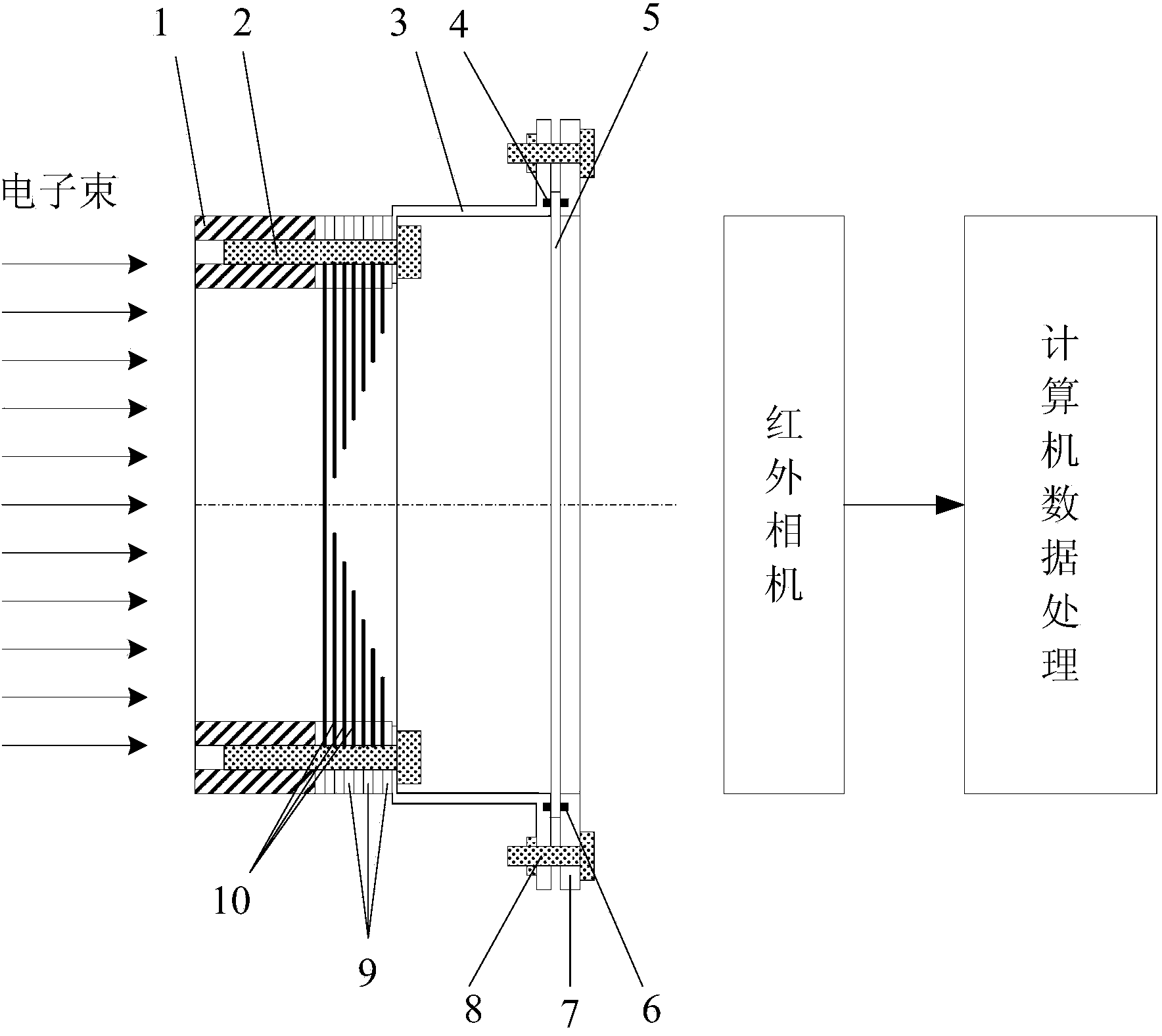

[0019] In the slice array calorimeter used for measuring the deposition depth distribution of high-current electron beam energy provided by the present invention, the slices absorbing electron beam energy are designed as circular rings whose inner radius gradually changes along the axial direction, and between two adjacent slices The polytetrafluoroethylene ring is used as the heat insulation material, and the sheet and the polytetrafluoroethylene ring are connected to the graphite collimation hole through the polytetrafluoroethylene screw. There is an infrared window at the end of the calorimeter. Outside the infrared window, through the infrared The camera shoots the infrared thermal radiation image of the sheet array, and sends it to the computer for image data processing to obtain the energy deposited on each layer of sheet, and gives the distribution of the measured electron beam energy deposition depth.

[0020] Graphite collimation hole, polytetrafluoroethylene ring, she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com