Testing device and testing method for mechanical parameters of non-standard rock test piece

A technology of rock specimens and mechanical parameters, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to meet the size, difficult to reflect the mechanical properties of rocks, damage and damage of the specimens, etc., and achieve a convenient loading rate. and loading times, improving convenience and intuitiveness, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

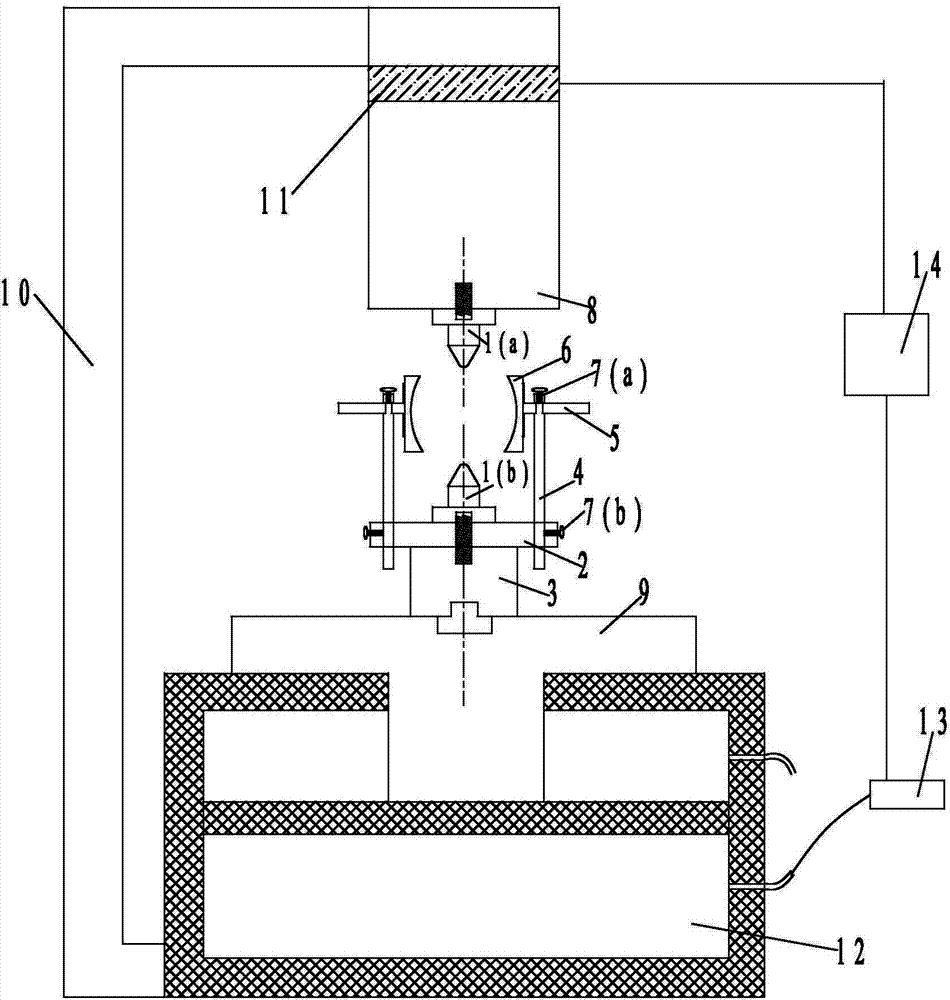

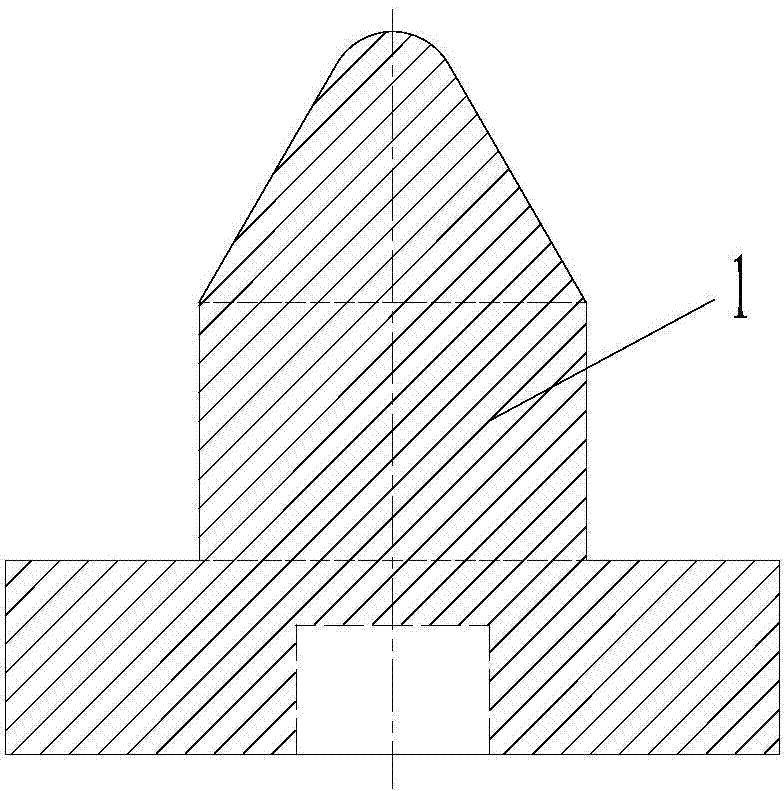

[0036] Such as figure 1 As shown, the non-standard rock specimen mechanical parameter testing device of the present invention includes a hydraulic pressure testing machine 10 for loading, a specimen clamping device, an upper loading cone 1 (a) and a lower loading cone 1 (b ), the hydraulic pressure testing machine 10 is composed of a frame main body, a hydraulic cylinder 12, a force transmission column 8, a pressure sensor 11 located on the force transmission column 8, a servo loading system 13 and a computer 14,

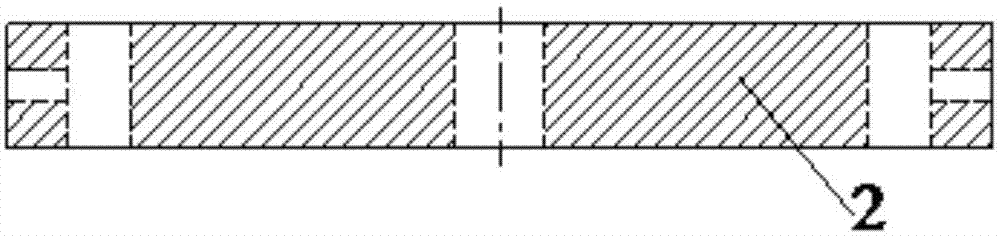

[0037] The structure of the specimen holding device is as follows: Figure 5 As shown: a height-adjustable backing column 3 is provided on the central axis of the hydraulic cylinder column head 9 of the pressure testing machine, and a backing plate 2 is provided on the backing post 3; Longitudinal rods 4; Horizontal push-pull hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com