Method for separating neutral aroma component from mainstream cigarette smoke

A technology of cigarette mainstream smoke and separation method, applied in the field of separation and identification, can solve the problems of aggravating the loss of smoke components and side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

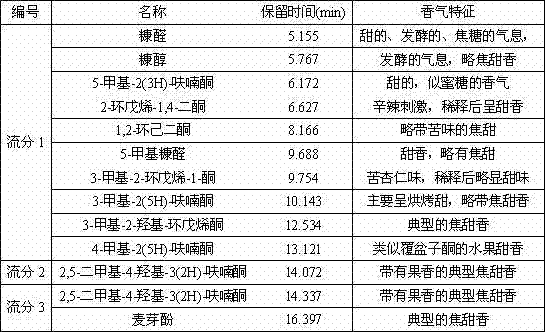

[0018] Separation method of burnt-sweet aroma components in mainstream smoke of Brazilian Luzhou-flavor single-material tobacco

[0019] According to the method stipulated in ISO3308 and GB / T 19609-2004, smoke 40 Brazilian strong-flavor single-material cigarettes on the smoking machine, extract the Cambridge filter with 60 ml of dichloromethane, remove the solvent, then add 10 ml of water, and shake fully Afterwards, freeze-dry to obtain the water-soluble components of mainstream smoke. Weigh 0.5 g of the above-mentioned water-soluble components, and use gel permeation chromatography to separate them. The filler is Sephadex G-10, distilled water is used as the mobile phase, and the flow rate is 3 mL / min. The collection process is monitored by an ultraviolet detector with a detection wavelength of 365 nm.

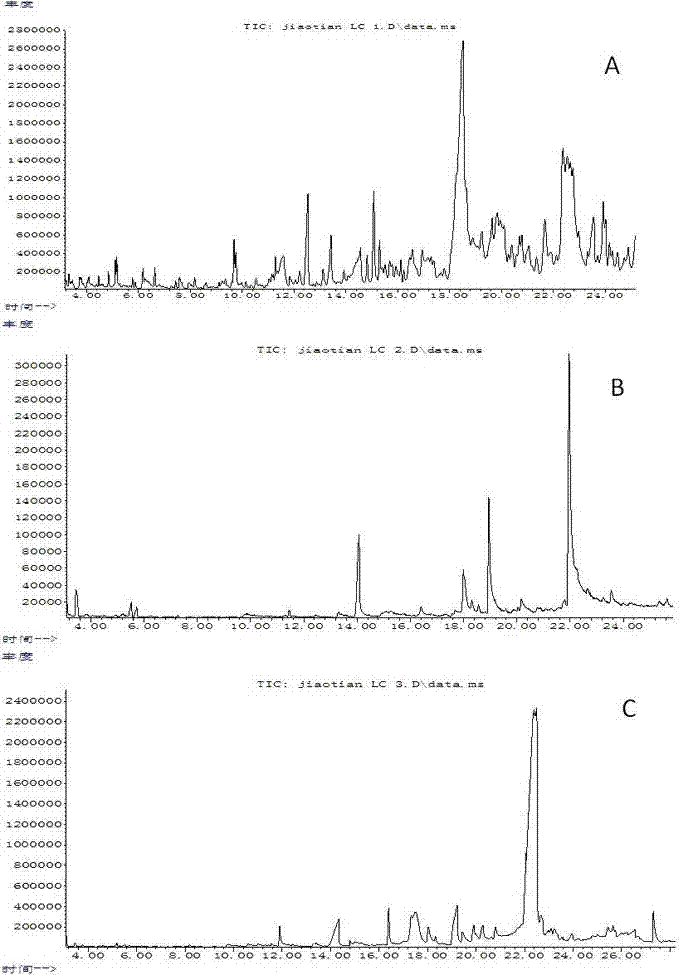

[0020] The automatic fraction collector collects a fraction every 3 minutes, and a total of 40 fractions are collected, labeled as F1, F2, F3, F4, F5, F6...F40. According t...

Embodiment 2

[0030] Separation method of burnt-sweet aroma components in mainstream smoke of Dajinyuan cigarettes

[0031] According to the methods specified in ISO3308 and GB / T 19609-2004, smoke 20 Dajinyuan cigarettes on a smoking machine, the ambient temperature is 22±2°C, and the humidity is 60±5%. Extract the Cambridge filter with 40 milliliters of ethyl acetate and remove the solvent, add 10 milliliters of water, shake fully, filter with a filter membrane with a pore size of 0.22 microns, freeze-dry to remove water, and obtain the water-soluble component of the mainstream smoke particulate matter. Weigh 0.5 g of the above-mentioned water-soluble components and separate them by gel permeation chromatography. The chromatographic column filler is Sephadex G-20, distilled water is used as the mobile phase, and the flow rate is 3 mL / min. The collection process is monitored by an ultraviolet detector with a detection wavelength of 365 nm.

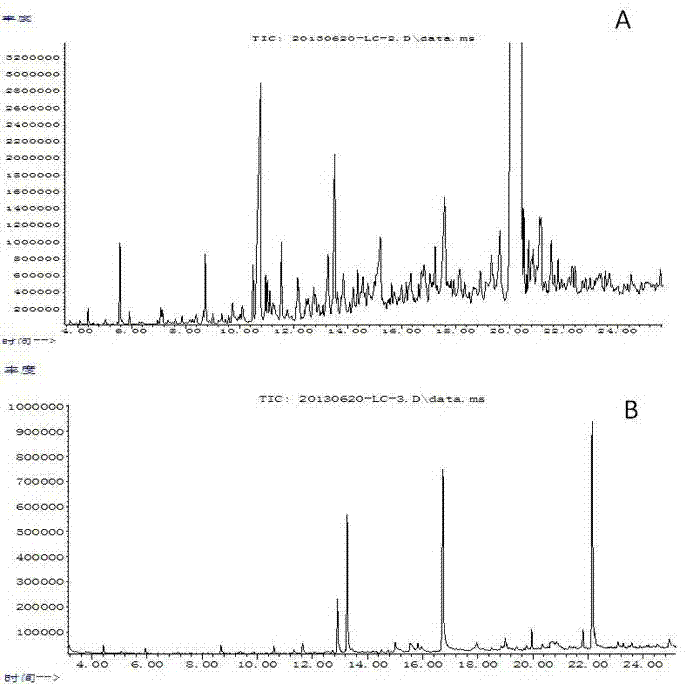

[0032]The automatic fraction collector collects o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com