Lignin conversion process

A technology of lignin and wood, applied in the field of lignin conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0172] I. Preparation of Lignin Feed Stream

[0173] Pre-Treatment of Lignin Stream The feed stream was produced from Arundoshida as the starting lignocellulosic biomass. Lignocellulosic biomass was pretreated according to the following steps:

[0174] - Lignocellulosic biomass was introduced into the continuous reactor and soaked at 155°C for 155min. The steeped mixture is passed through a compressor to separate the steeping liquid containing sugars and the lignocellulosic biomass and the fraction containing solid steeping raw materials. The portion containing the solid soak material was steam exploded at 195°C for 4 min.

[0175] The steam explosion products are separated into steam explosion liquid and steam explosion solid.

[0176] - Mixing the steam explosion solids with water to obtain a mixture with a dry matter content of 7.5% and feeding the mixture into the enzymatic hydrolysis reactor. An enzyme mix was added corresponding to a concentration of 15 mg protein pe...

Embodiment 1

[0206] Example 1 - Need for Lignocellulosic Biomass Pretreatment

[0207] 5.56 g of unpretreated lignocellulosic biomass was reacted in the presence of 10 g water, 6.0 g Johnson Mather A-5000 sponge nickel catalyst (50 wt% water / 50 wt% catalyst). The reactor was pressurized to a hydrogen pressure of 77.5 bar at 25°C. The reaction temperature is 350° C., corresponding to an operating pressure in the range of 170-200 bar; the reaction time is 1.5 h. The reaction product was determined according to method N.1. The resulting reaction product has a large amount of unconverted solids and little or no hydrocarbons. Therefore, the need for preprocessing was identified.

Embodiment 2

[0208] Example 2 - Conversion of a lignin feed stream to a phenolic-rich converted lignin stream

[0209] 5 g of a lignin feed stream at approximately 50% humidity were reacted in the presence of 18.00 g water, 1.20 g Johnson Mather A-5000 sponge nickel catalyst (50 wt% water / 50 wt% catalyst). The reactor was pressurized to a hydrogen pressure of 13.8 bar at 25°C. The reaction temperature was 305° C., corresponding to an operating pressure in the range of 89-93 bar; reaction time 1.0 h.

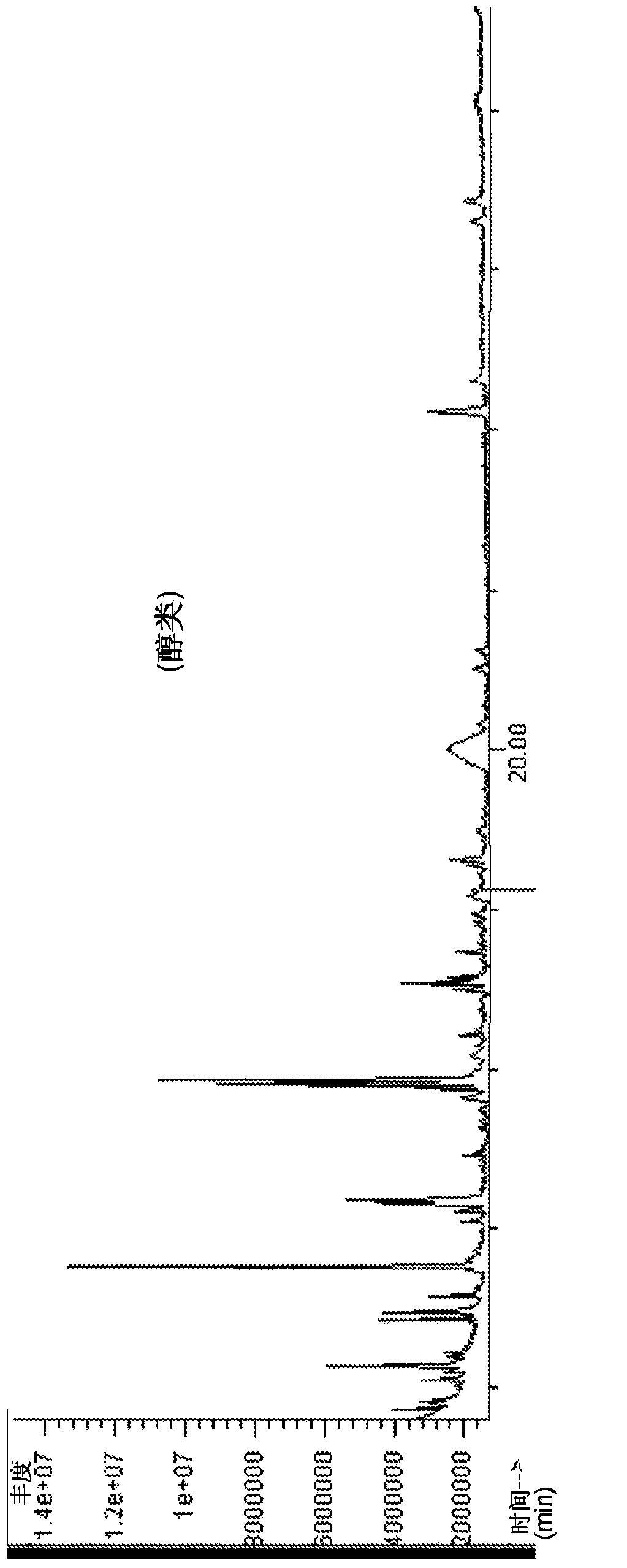

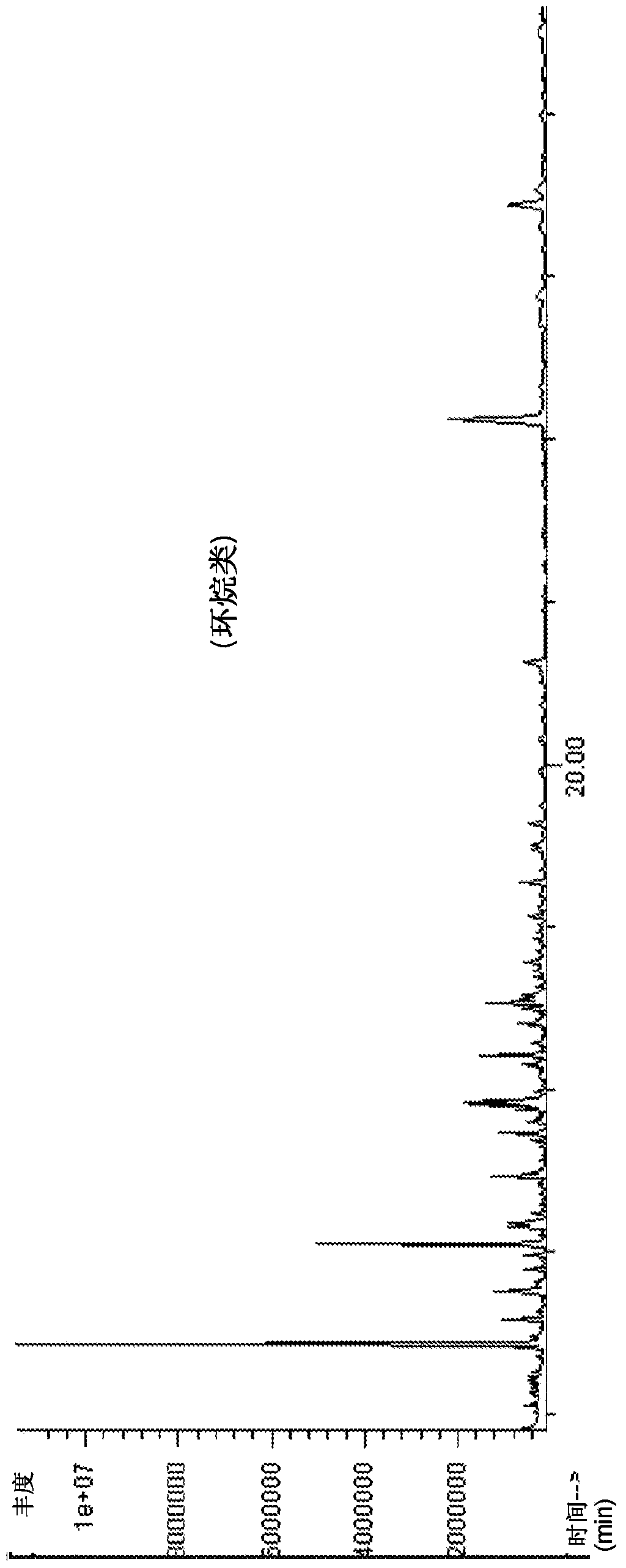

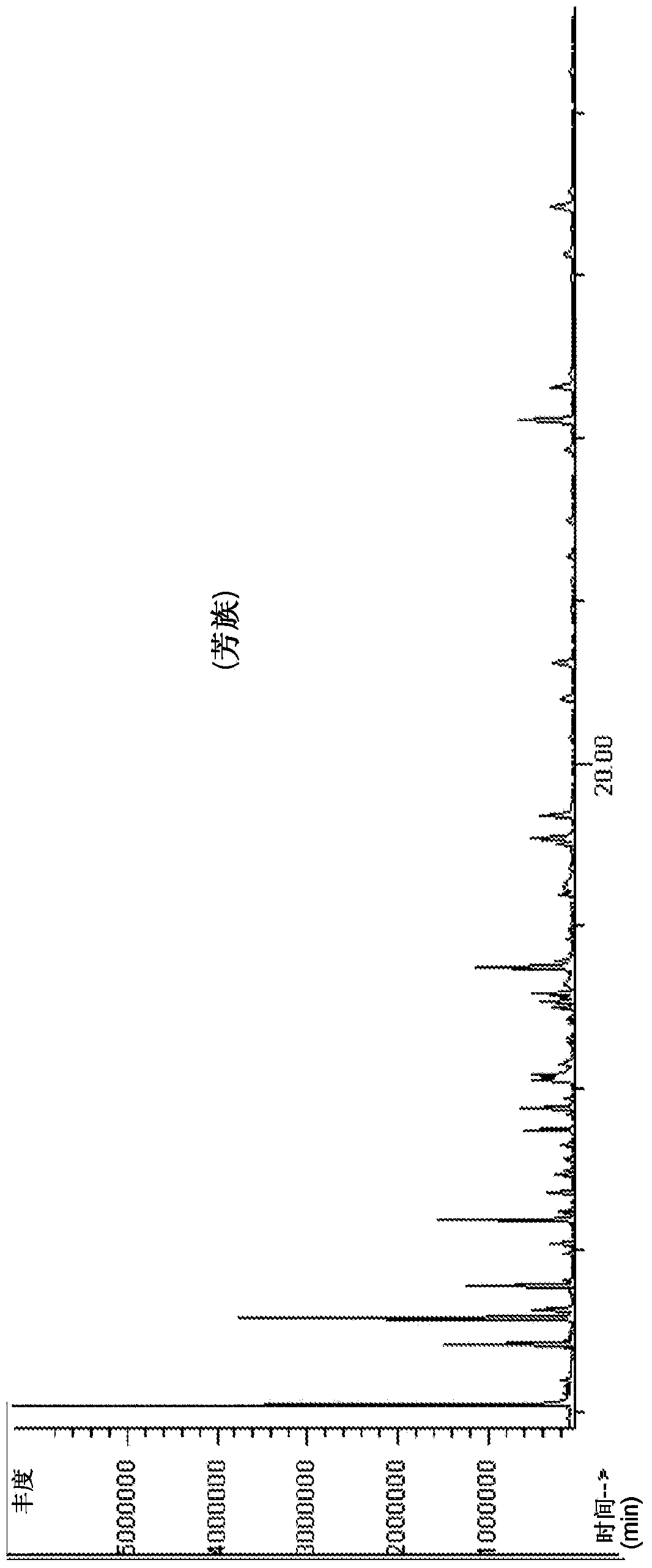

[0210] The reaction product was determined according to method N.2. The composition of the reaction product is reported in Table 2. Phenolic compounds are the major components of the converted lignin feed stream. A sample curve for this converted lignin stream is Figure 4 shown.

[0211] Table 2. Composition of phenolic-rich converted lignin stream

[0212]

[0213]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com