Pipe machining device

A technology for processing equipment and pipes, applied in the field of plastic pipe processing and cutting equipment, can solve the problems of large energy consumption, splashing chips, uneven cutting section, etc., and achieve the effect of reducing motor drive, reducing cutting chips, and smoothing cutting section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

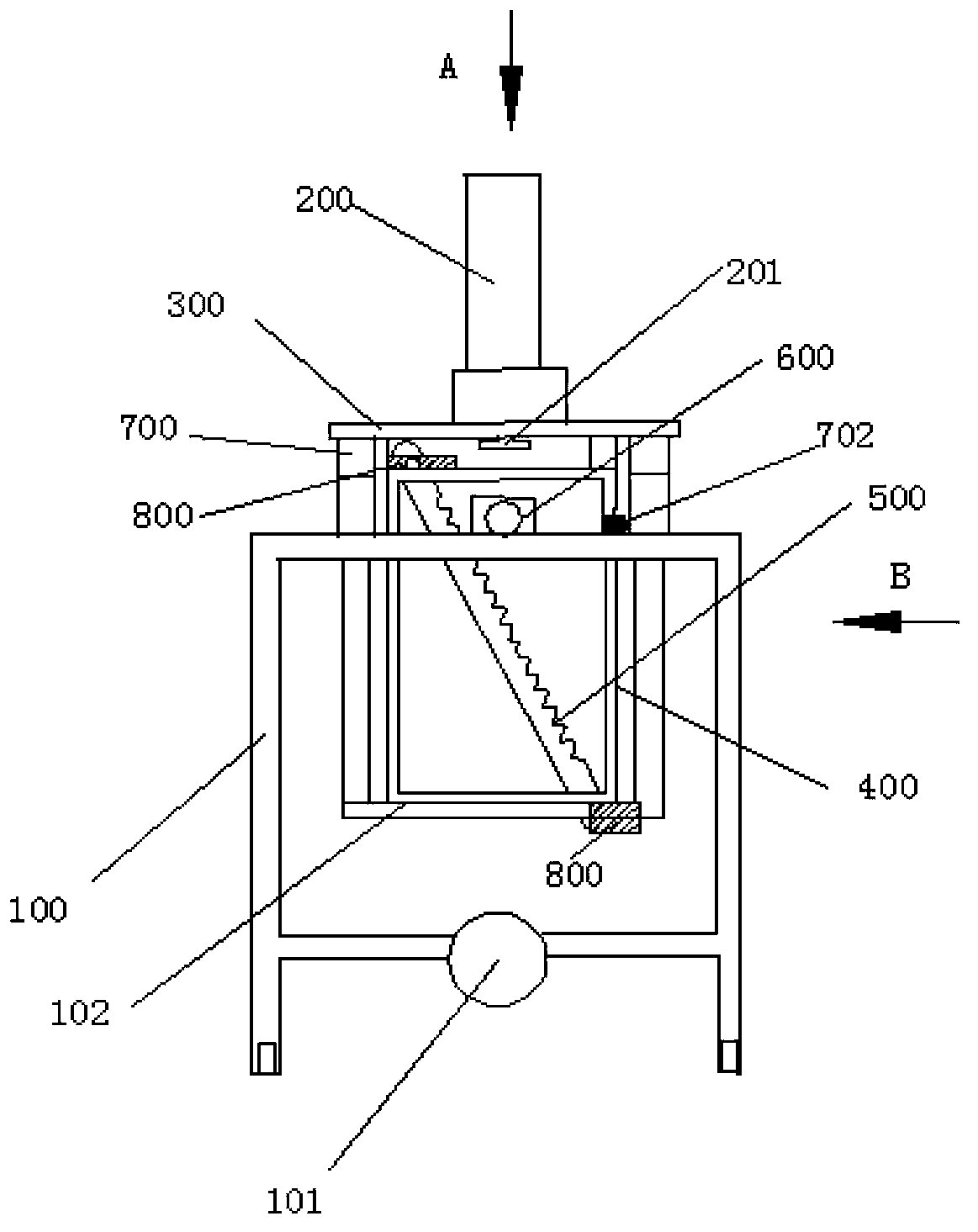

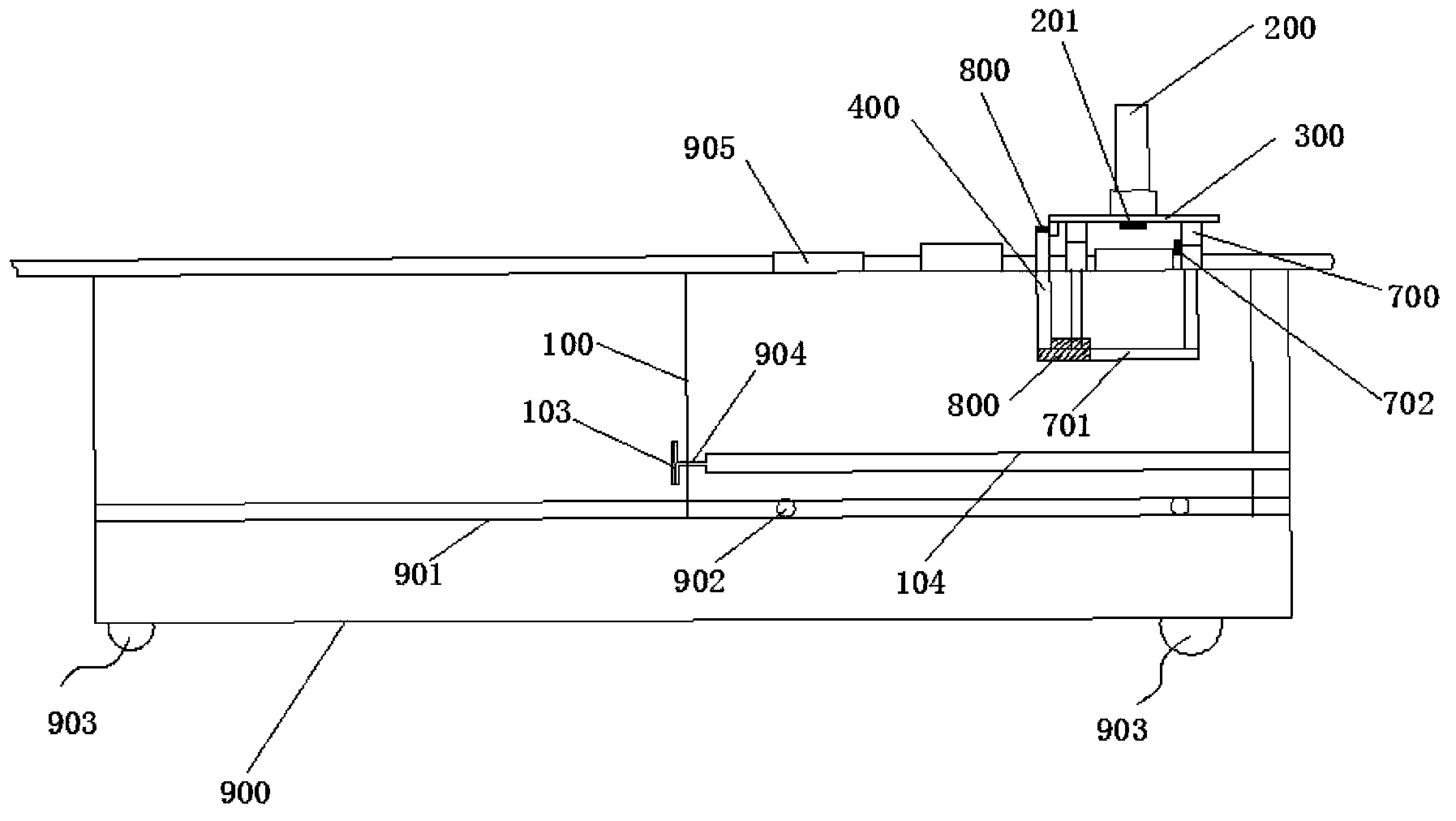

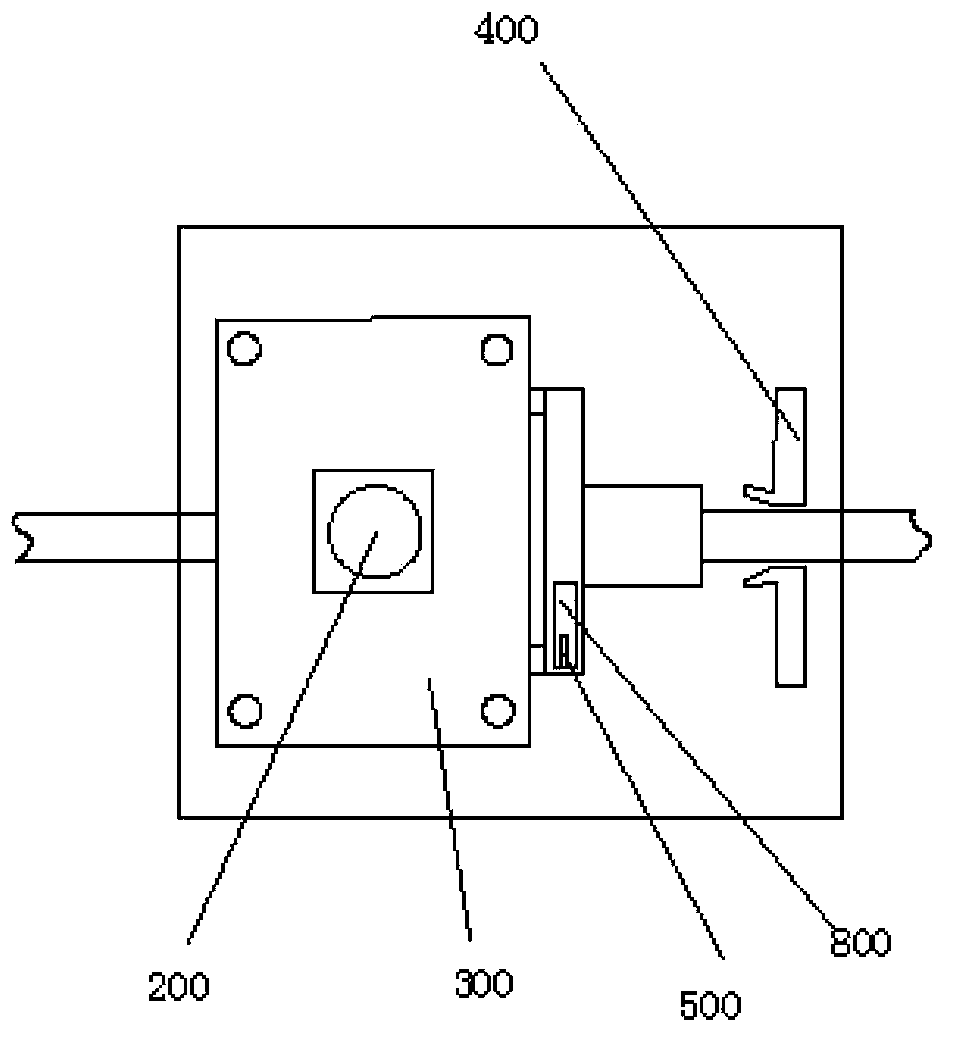

[0015] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0016] A steel-plastic composite pipe extrusion equipment in this preferred embodiment, such as Figure 1-3 As shown, a pipe processing equipment includes a base 900, a frame 100, a moving device and a processing device, the frame 10 is fixed on the base 900, and the processing device and the moving device are respectively connected with the frame 100 Fixedly connected, the described walking device comprises a lifting support 300 and a moving cylinder 200, the lifting support 300 is connected with the frame 100 through the moving cylinder 200, and the described processing device comprises a vertical knife rest 400 and a cutting blade 500, and the vertical knife rest The two ends of 400 are respectively fixedly connected to the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com