Spiral strip filler

A strip and spiral technology, applied in the field of biological fillers, can solve the problems of insufficient specific surface area and insufficient specific surface area, and achieve the effects of improving processing efficiency, improving utilization rate and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

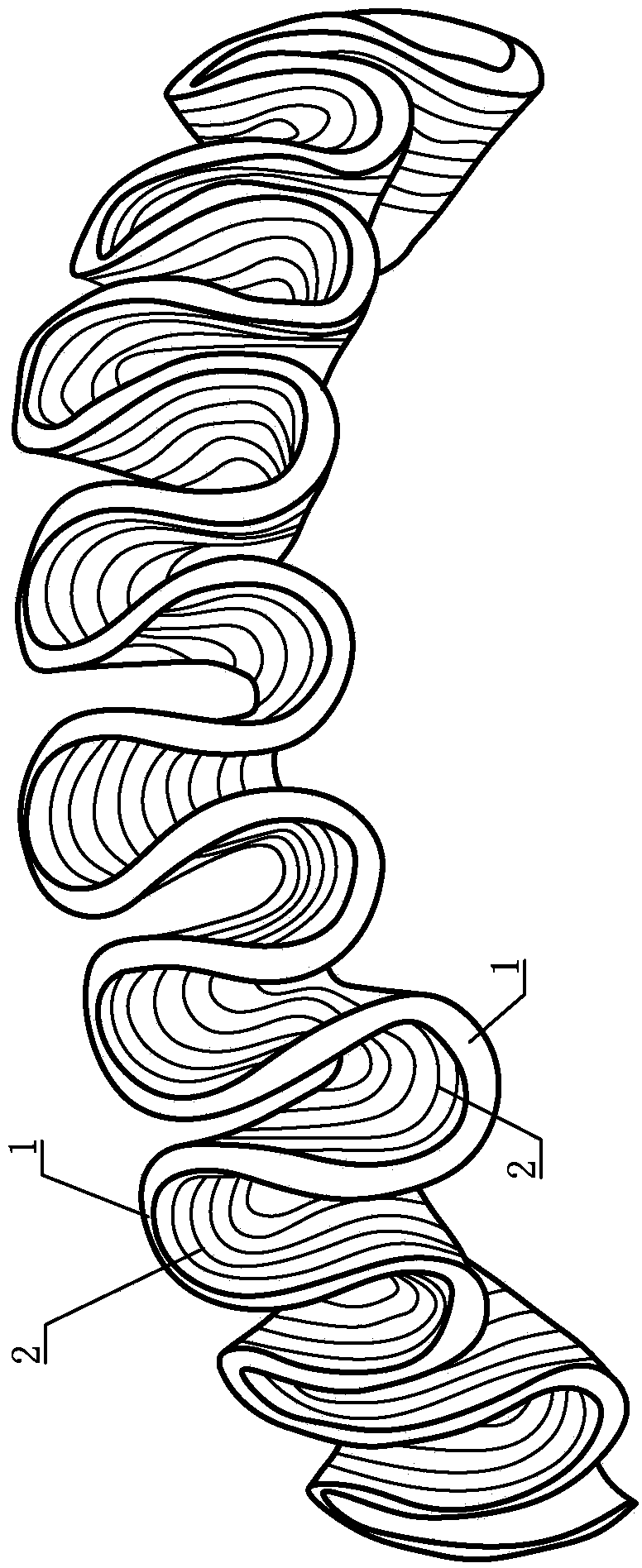

[0024] figure 1 The middle mark 1 is a fold, and 2 is a ditch.

[0025] Such as figure 1 The shown embodiment of a spiral strip packing includes a bent strip-shaped packing body, the packing body includes continuous "S"-shaped folds, and each fold 1 of the folds encloses a semi-closed space for fluid to enter. The semi-enclosed space is trumpet-shaped or funnel-shaped, and the folded surface forms a microbial attachment surface.

[0026] In this embodiment, the "S"-shaped folds formed on the filler body increase the specific surface area and the attachment area of microorganisms, making it easier for microorganisms to attach to the surface. When water or air flows through the pleats, it swirls in the semi-enclosed space surrounded by the pleats 1 to form a vortex, and the microorganisms are fully mixed with gas and water, which effectively improves the utilization rate of water and gas, and improves the treatment efficiency. At the same time, when the curved strip-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com