Flame-retardant epoxy resin suitable for vacuum infusion and preparation method of flame-retardant epoxy resin

A technology of epoxy resin and vacuum infusion, which is applied in the field of flame-retardant composite materials, can solve the problems that the mechanical properties of materials in high-end technical fields cannot be met, the flame retardancy of materials cannot meet the requirements, and the vacuum infusion process cannot be applied. Easy production and implementation, excellent mechanical properties and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

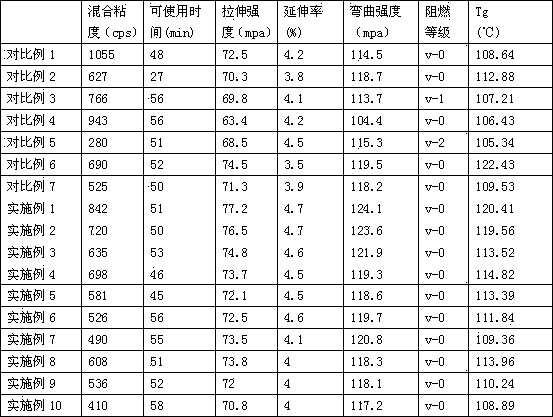

Examples

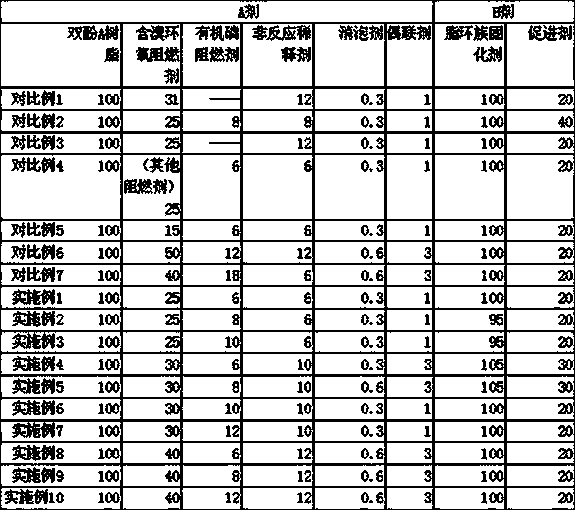

Embodiment 1

[0098] Preparation of Agent A: heat 100 parts of bisphenol A resin to 120°C; add 25 parts of brominated epoxy flame retardant and start stirring to fully dissolve the brominated epoxy flame retardant; after stirring for 60 minutes, place and cool to 60°C; Add 6 parts of organophosphorus flame retardant, keep stirring at the same speed for 30 minutes, the stirring speed is 30-90r / min, and the stirring temperature is 60°C; stop heating, add 0.3 parts of defoamer and 1 part of coupling agent, and stir for 30 minutes Minutes; keep stirring, cool the resin to below 40°C; add 6 parts of non-reactive diluent, start vacuum defoaming after stirring for 30 minutes and defoaming for 30 minutes while stirring, stop stirring, and set aside for later use.

[0099] Preparation of agent B: Mix 100 parts of alicyclic amine curing agent and 20 parts of accelerator, mix well, stir for 60 minutes at a stirring speed of 20-50 r / min, and set aside for later use.

[0100] Data test: Weigh 100 parts ...

Embodiment 2

[0102] Preparation of agent A: heat 100 parts of bisphenol A resin to 115-125 ° C; add 25 parts of brominated epoxy flame retardant and start stirring to fully dissolve the brominated epoxy flame retardant, stir for 50-70 minutes, then let it cool to 55-65°C; add 8 parts of organophosphorus flame retardant, keep stirring at the same speed for 20-40 minutes, the stirring speed is 30-90r / min, and the stirring temperature is 55-65°C; stop heating, add defoamer 0.3 1 part and 1 part of coupling agent, stir for 30 minutes; keep stirring, cool the resin to below 40°C; add 6 parts of non-reactive diluent, stir for 30 minutes, start vacuum defoaming and defoaming for 20-40 minutes while stirring , stop stirring, and set aside.

[0103] Preparation of agent B: Mix 95 parts of alicyclic amine curing agent and 20 parts of accelerator, mix well, stir for 50-70 minutes at a stirring speed of 20-50 r / min, and set aside for later use.

[0104] Data test: Weigh 100 parts of component A and 2...

Embodiment 3

[0106] Prepare agent A: Heat 100 parts of bisphenol A resin to 120°C; add 25 parts of brominated epoxy flame retardant and start stirring to fully dissolve the brominated epoxy flame retardant. After stirring for 60 minutes, let it cool to 55-65 ℃; add 10 parts of organophosphorus flame retardant, keep stirring at the same speed for 30 minutes, the stirring speed is 30-90r / min, and the stirring temperature is 55-65℃; stop heating, add 0.3 parts of defoamer and 1 part of coupling agent Keep stirring, cool the resin to below 40°C; add 6 parts of non-reactive diluent, stir for 30 minutes, start vacuum defoaming and defoaming for 30 minutes while stirring, stop stirring, and set aside for later use.

[0107] Preparation of agent B: Mix 100 parts of alicyclic amine curing agent and 20 parts of accelerator, mix well, stir for 60 minutes at a stirring speed of 20-50 r / min, and set aside for later use.

[0108] Data test: Weigh 100 parts of component A and 20 parts of component B, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com