Gas end cylindrical surface combined sealing device provided with spiral groove

A sealing device and end face sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of deformation of sealing position, decrease of system working stability, excessive leakage, etc., so as to reduce contact wear and realize deformation The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

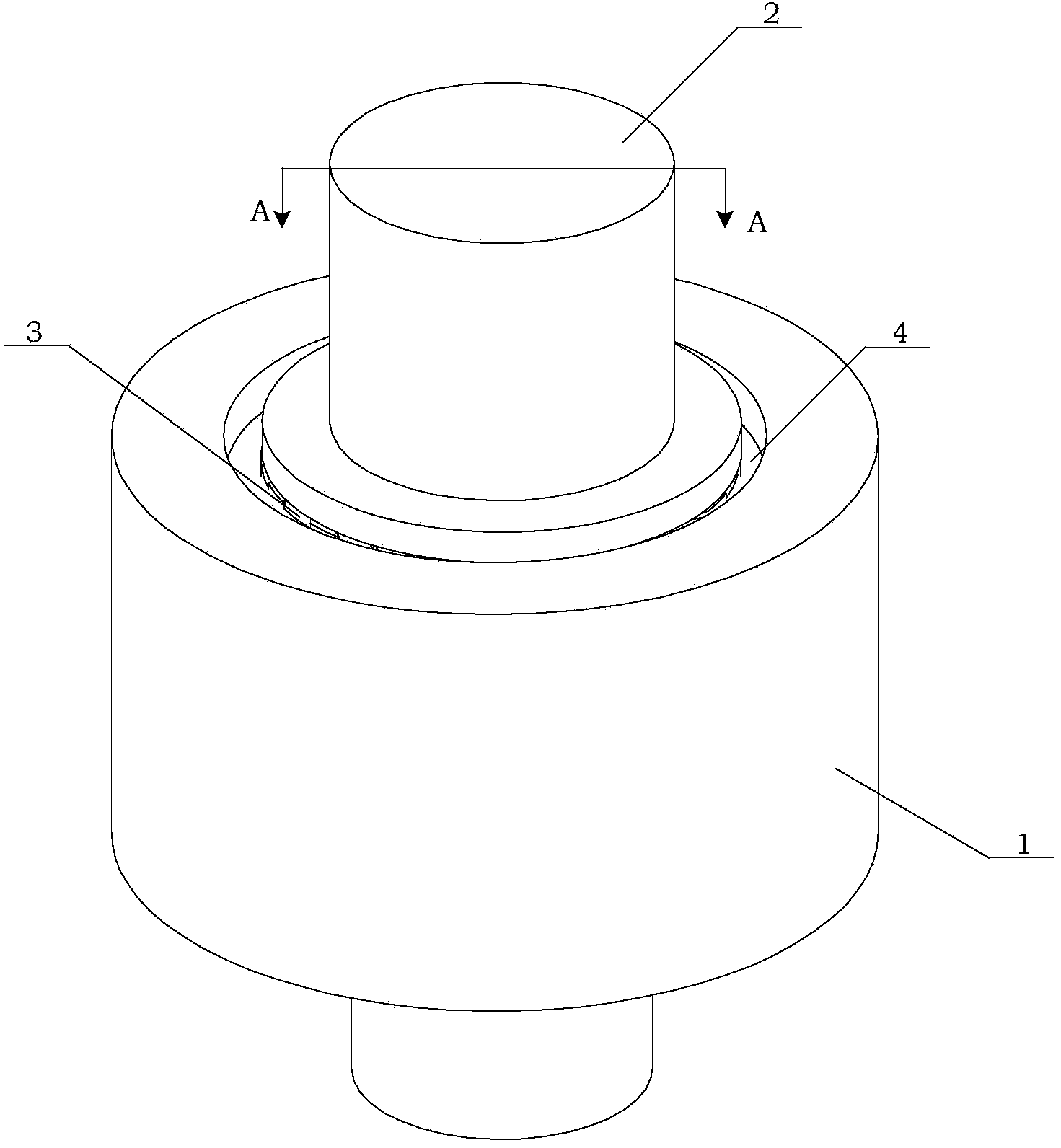

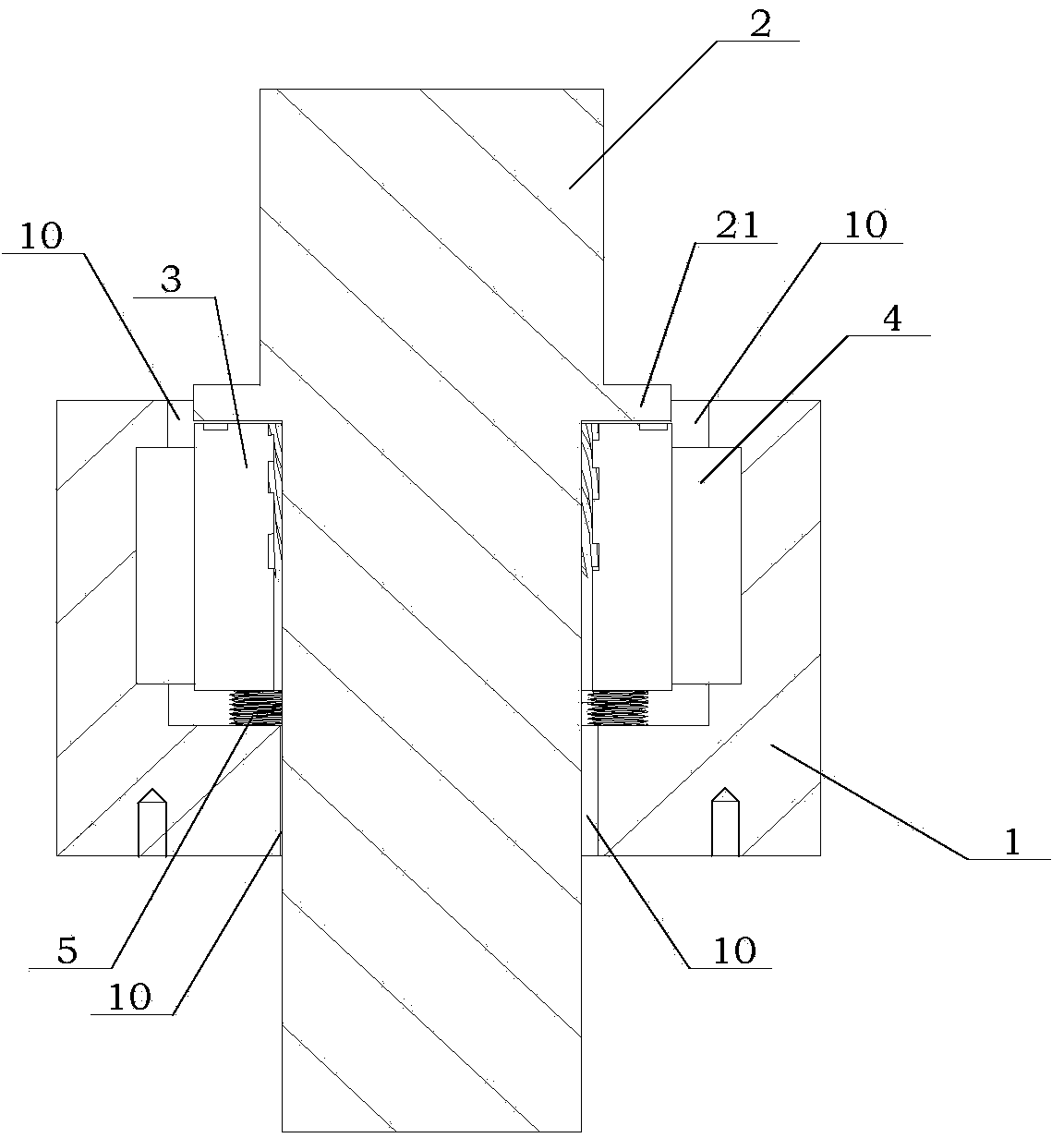

[0041] See figure 1 , Figure 1A , Figure 1B , Figure 1C As shown, the present invention is a gas-end cylindrical combined sealing device with spiral grooves. The sealing device includes a base 1, an end cylindrical floating seal ring 3, a cylindrical elastic support ring 4, and an end elastic support. 5; The end cylindrical floating seal ring 3 is installed with the rotating shaft of the existing high-speed rotating machinery, that is, the rotor journal 2; the end cylindrical floating seal ring 3 and the cylindrical surface are sequentially installed outside the rotor journal 2 After the elastic support ring 4 and the base 1 are formed, the gas-end cylindrical component sealing device with elastic support and spiral groove designed in the present invention is formed.

[0042] (1) Base 1

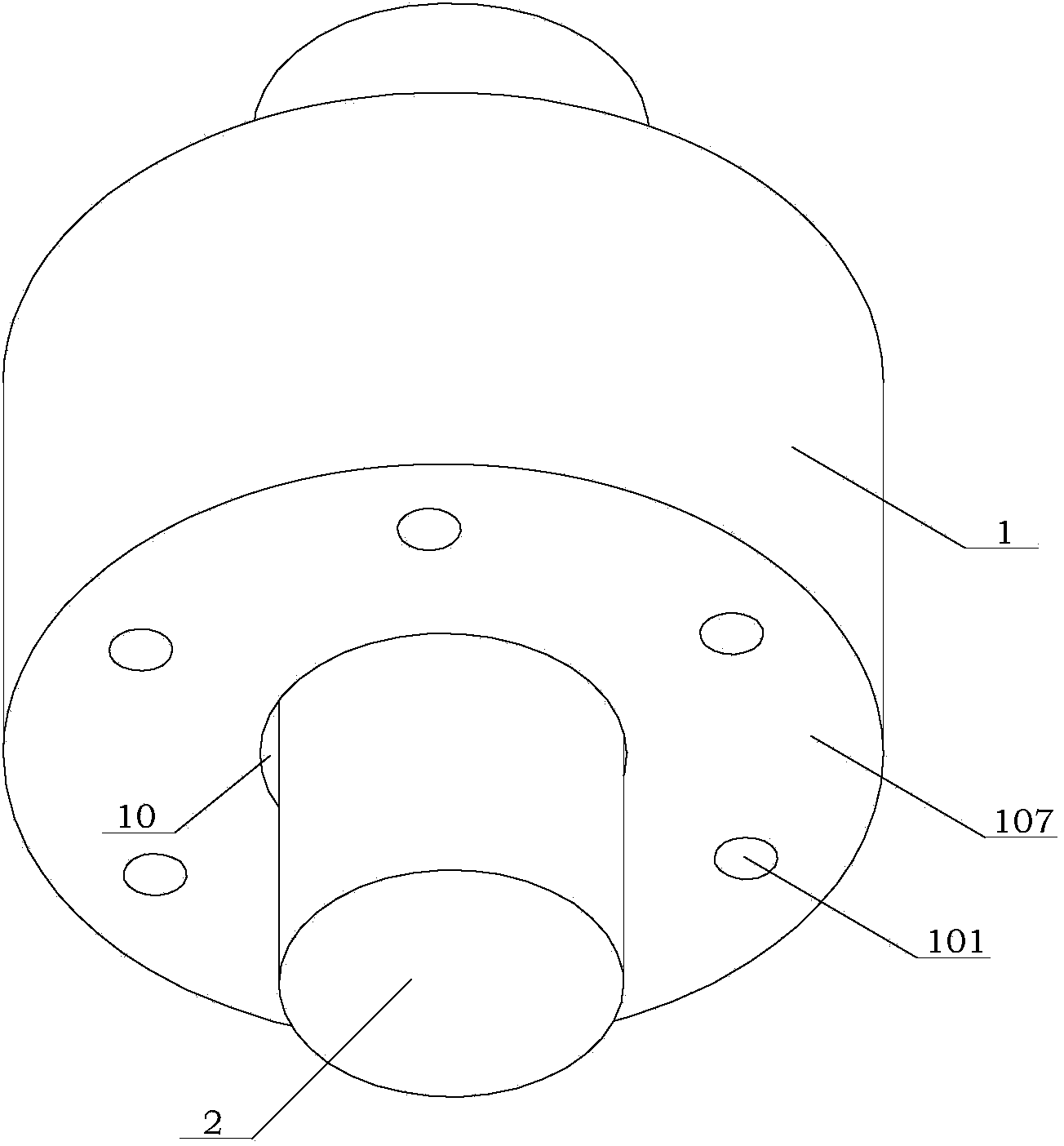

[0043] See figure 2 , Figure 2A As shown, the base 1 is an integrally fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com