Ground source heat pump drying device

A drying device and ground source heat pump technology, applied in the direction of drying gas arrangement, heat pump, drying, etc., can solve the problems of conflicting energy policies, multiple energy sources, increasing the cost of mechanical drying, etc., and achieve the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

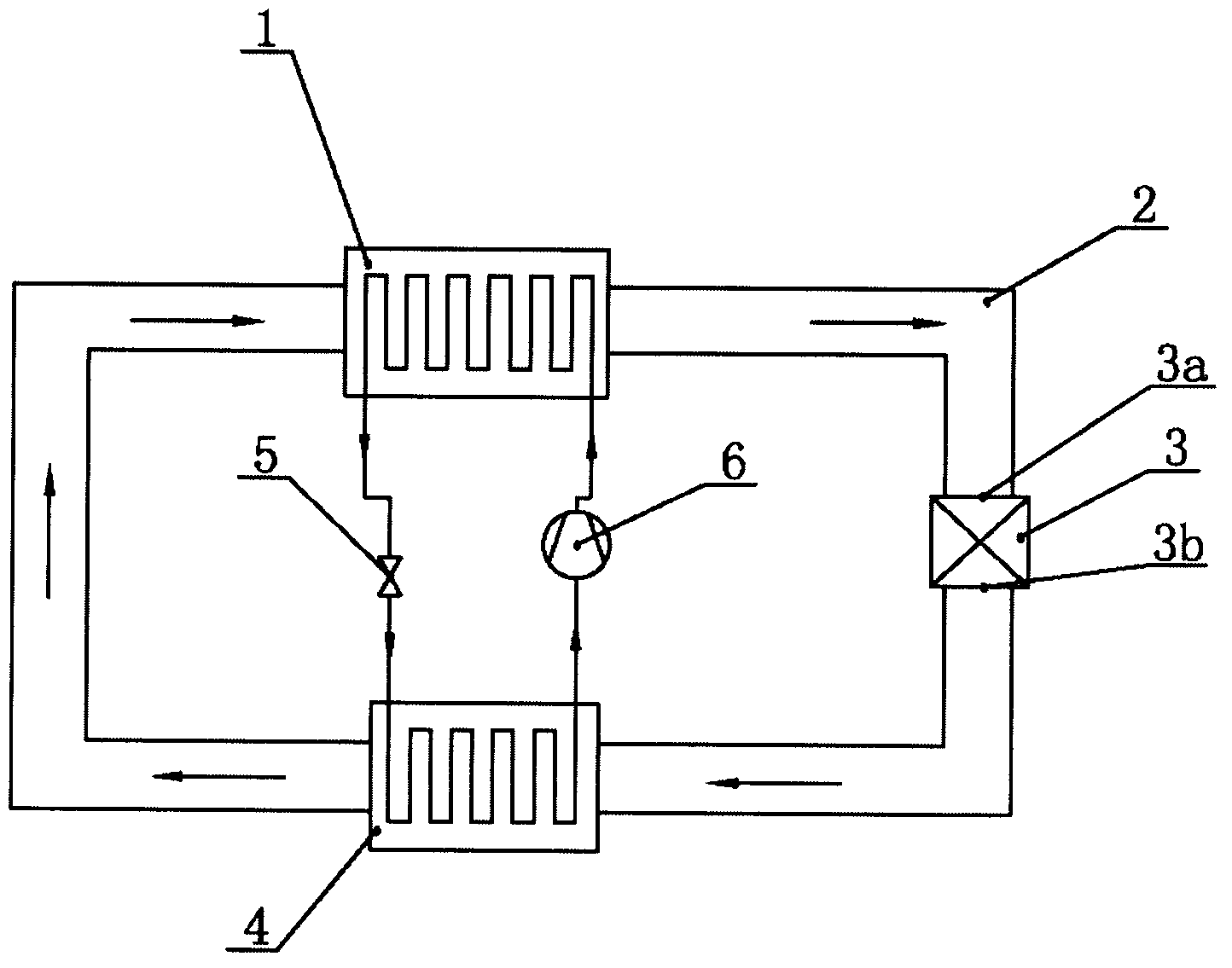

[0010] Such as figure 1 As shown, a ground source heat pump drying device includes a condenser 1 and an evaporator 4, a compressor 6 is arranged in series between the output end of the evaporator 4 and the input end of the condenser 1, and the output end of the condenser 1 is connected to the evaporator A throttling valve 5 is arranged in series between the input ends of the condensers 4, a loop pipe 2 passing through the condenser 1 and the evaporator 4 is arranged inside the condenser 1 and the evaporator 4, and a drier 3 is arranged on the loop pipe 2, The air discharge port 3b of the dryer 3 is connected to the evaporator 4, and the air inlet port 3a of the dryer 3 is connected to the condenser 1.

[0011] When the present invention works, the working medium stored in the heat pump system first absorbs the heat of the waste gas discharged from the air discharge end 3b of the drier 3 in the evaporator 4, is vaporized and becomes steam, and then enters the condenser through ...

Embodiment 2

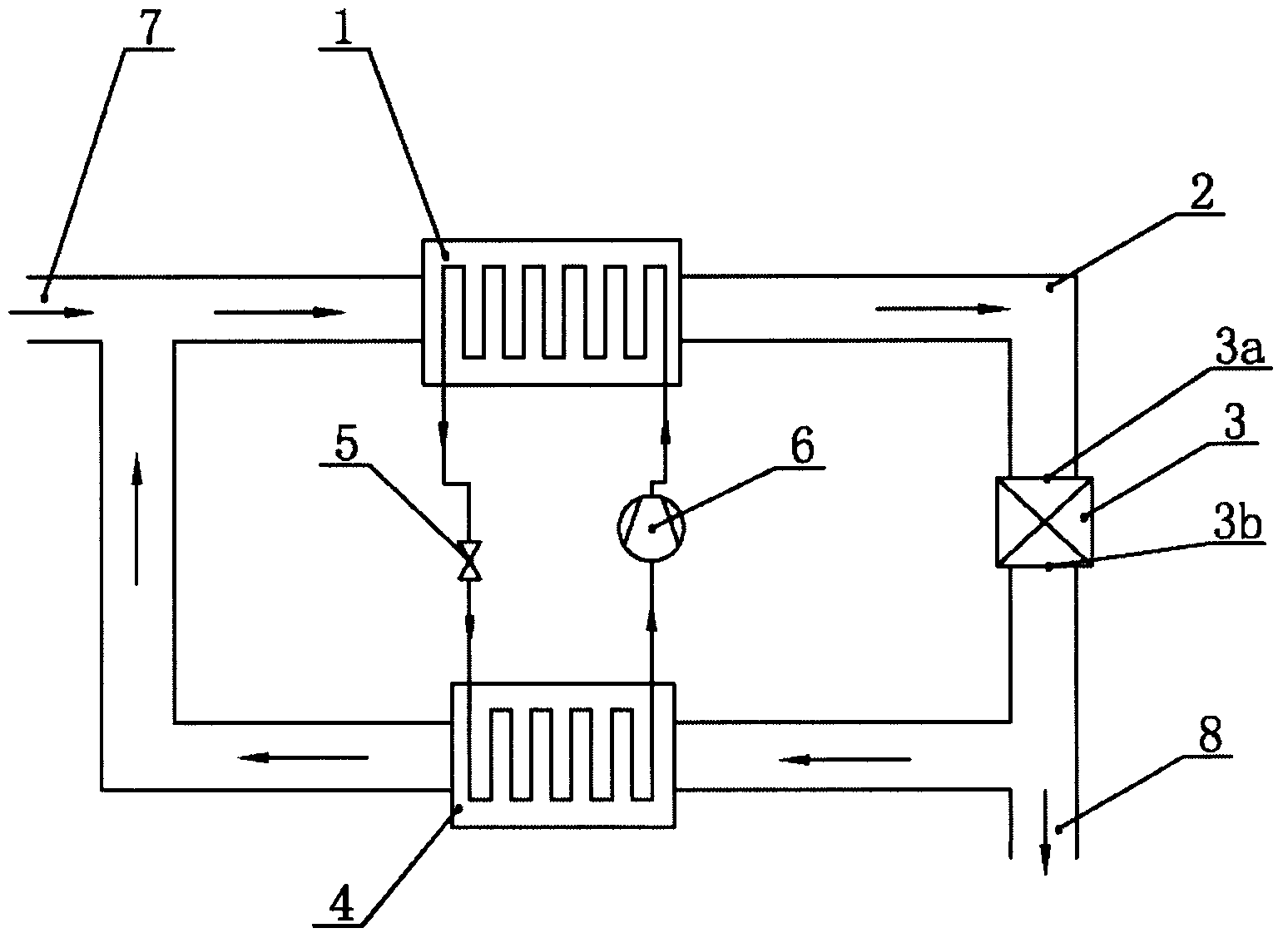

[0013] Such as figure 2 As shown, a ground source heat pump drying device includes a condenser 1 and an evaporator 4, a compressor 6 is arranged in series between the output end of the evaporator 4 and the input end of the condenser 1, and the output end of the condenser 1 is connected to the evaporator A throttling valve 5 is arranged in series between the input ends of the condensers 4, a loop pipe 2 passing through the condenser 1 and the evaporator 4 is arranged inside the condenser 1 and the evaporator 4, and a drier 3 is arranged on the loop pipe 2, The air discharge end 3b of the drier 3 is connected to the evaporator 4, the air inlet end 3a of the drier 3 is connected to the condenser 1, and an air inlet 7 is arranged on a section of the loop pipeline 2 far away from the drier 3, and an air inlet 7 is arranged on the loop pipeline. An air outlet 8 is provided on a section of pipeline between the dryer 3 and the evaporator 4 .

[0014] When the present invention works...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com