Sample frame for testing sample plates

A sample rack and template technology, which is applied in the field of natural environment test technology, can solve the problems of large volume, large site area, and restrictions on the amount of sample input, and achieve the effects of reducing detection time, saving space, and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

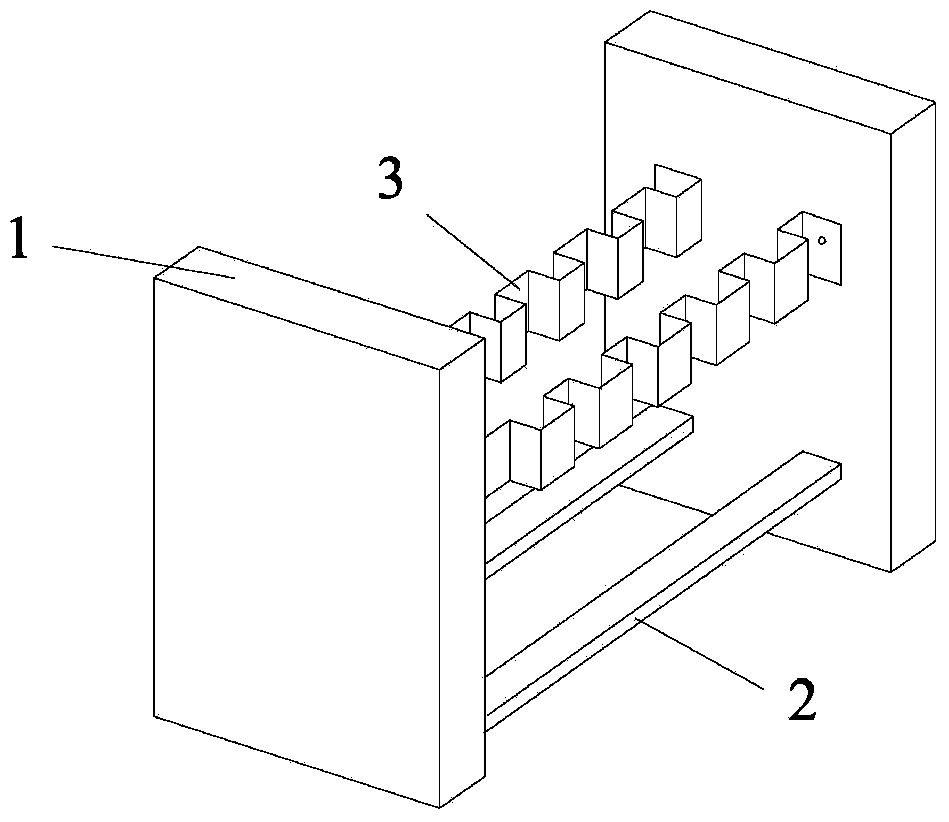

[0021] Take the wooden sample rack for storing 12 double-sided paint samples of 150mm*75mm*3mm as an example to describe in detail, the structure is as attached figure 1 shown.

[0022] The fixed vertical plate is 110mm*95mm*6mm, the horizontal support plate is 225mm*30mm*8mm, the tooth frame is evenly distributed with 12 rectangular slots of 20mm*10mm, and the horizontal support plate and the fixed vertical plate are connected in a conventional way. Install the toothed frame on the fixed vertical plate 90 mm above the horizontal support plate, the toothed frame is parallel to the horizontal support plate, and the structure is as attached figure 1 As shown, the sample holder for the test sample was obtained.

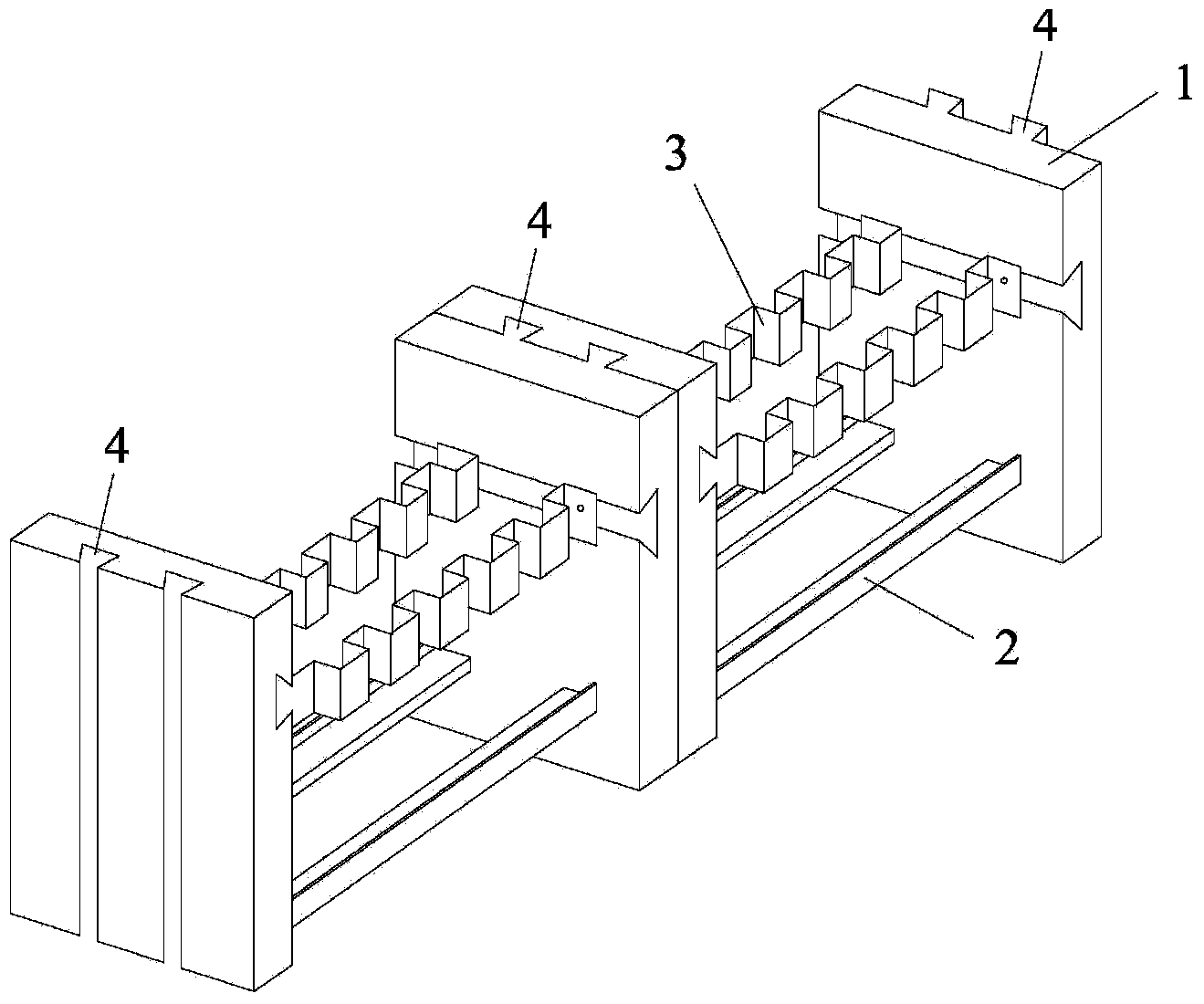

[0023] Two pairs of parallel vertical occlusal grooves 4 are respectively processed on the outside of the vertical plate, which can realize multiple groups of horizontal assembly combinations. The structure is as follows: figure 2 shown.

[0024] Two sets of parallel...

Embodiment 2

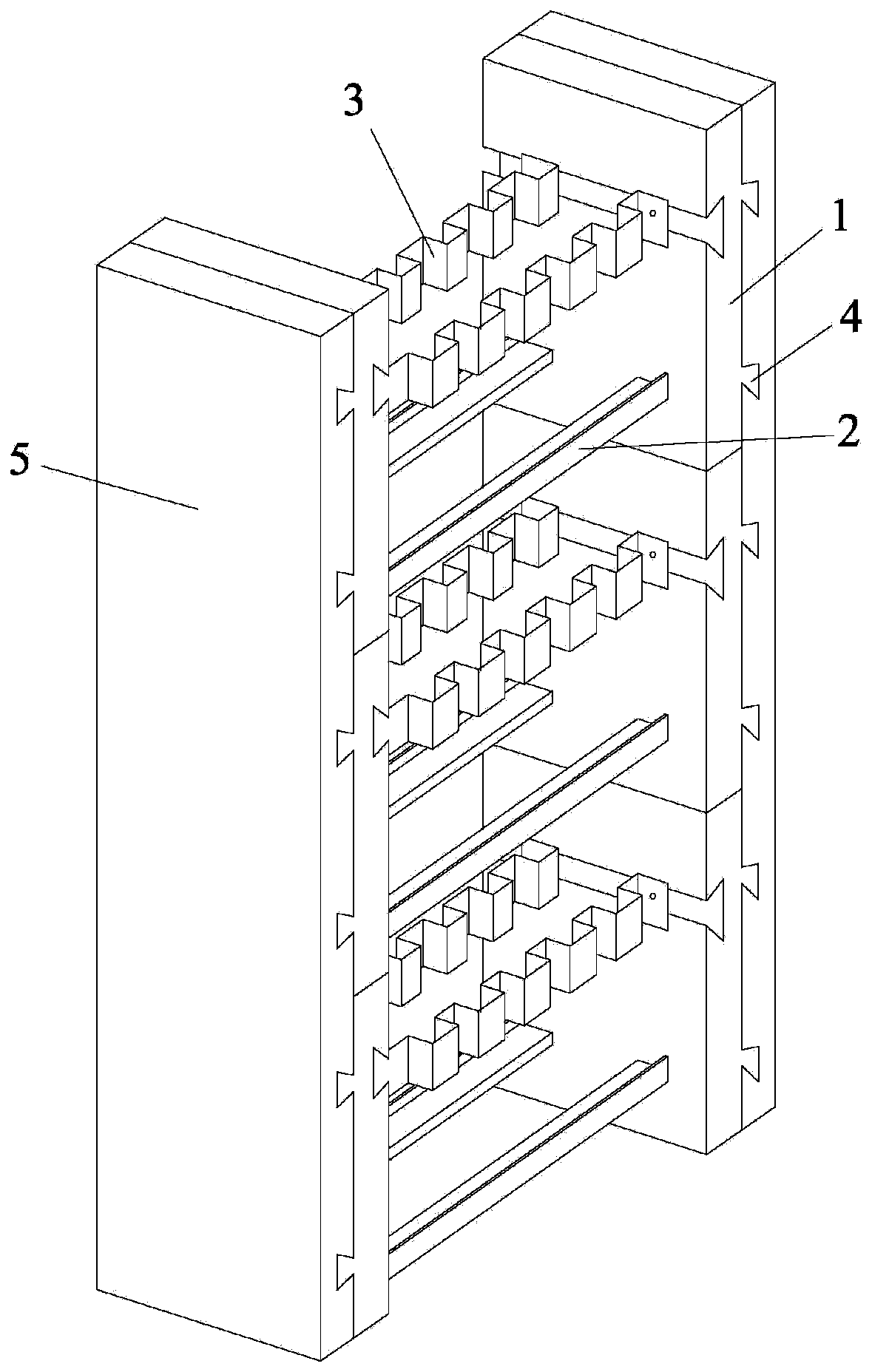

[0026] Take the wooden sample rack for storing 24 double-sided coating samples of 85mm*85mm*5mm as an example to describe in detail, the structure is as attached Figure 4 shown.

[0027] The fixed vertical plate is 110mm*70mm*6mm, the horizontal support plate is 225mm*30mm*8mm, and the L structure with a side height of 15 mm. The toothed frame is evenly distributed with 24 rectangular slots of 20mm*10mm, at the position of 20mm from the top of the vertical plate. A pair of dovetail grooves 6 are arranged horizontally to adjust the horizontal spacing of the toothed frame; connect the horizontal support plate and the fixed vertical plate in a conventional manner. The distance between the toothed frame and the horizontal support plate is 50 mm, parallel to the horizontal support plate, and the structure is as attached Figure 4 As shown, the sample holder for the test sample was obtained.

[0028] Two pairs of parallel occlusal grooves 4 are respectively processed on the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com