Manufacturing method for inner electrode of chip component

A manufacturing method and technology of components, applied in the manufacture of resistors, electrical components, capacitors, etc., can solve problems such as electrode deformation, silver paste waste, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

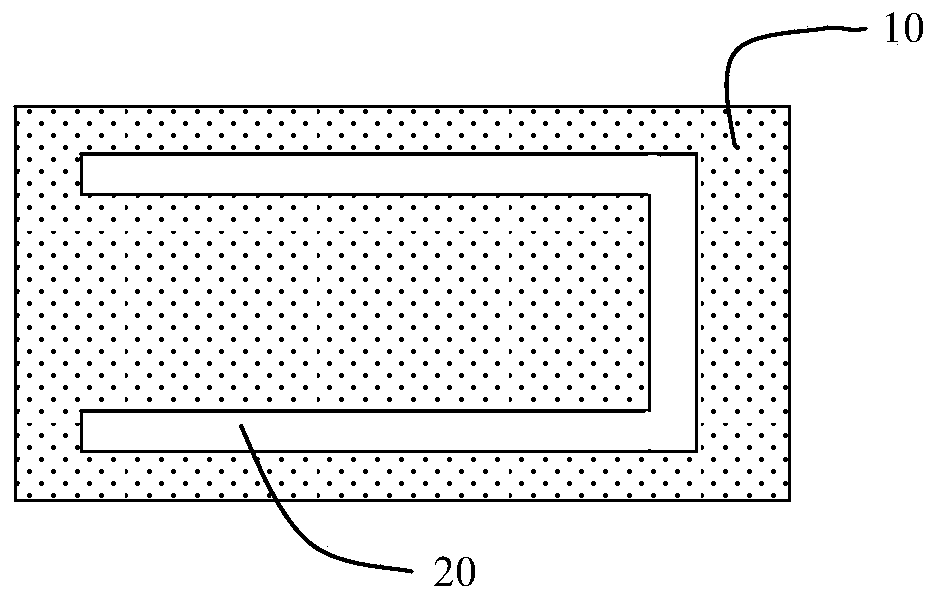

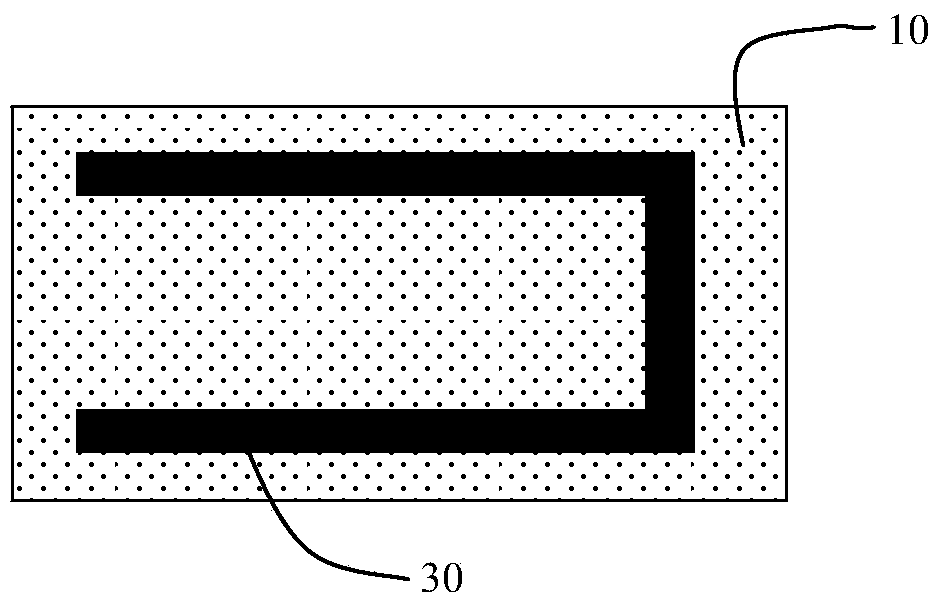

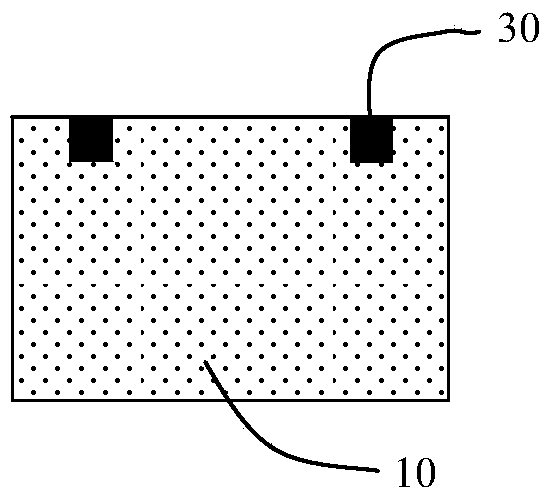

[0025] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0026] The embodiment of the present invention discloses a method for manufacturing high-precision ultra-fine internal electrodes of chip components, wherein the ceramic casting slurry in this embodiment is composed of glass powder, binder, dispersant, solvent and plasticizer. Specifically, the glass powder is MGA powder, the particle size D50 is 1-3 μm, and the binder can be Rohm and Haas Paraloid TM Laubola thermoplastic acrylic resin A-21, the dispersant can adopt high-performance phosphite antioxidant S9228, the solvent can adopt the mixture of ethyl acetate and isopropanol, and the plasticizer can adopt hexadiene Dioctyl acid.

[0027] The method for manufacturing high-precision ultra-fine inner electrodes of chip components in this embodiment includes the following steps:

[0028] (1) Prepare ceramic casting slurry by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Viscosity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com