Method for improving in-plane uniformity of reliability of SONOS flash device

A flash memory device and reliability technology, applied in the fields of electric solid state device, semiconductor device, semiconductor/solid state device manufacturing, etc., can solve the problems of uncontrolled, partial voltage influence, and affecting the reliability performance of SONOS flash memory device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for improving the in-plane uniformity of SONOS flash memory device reliability of the present invention comprises steps:

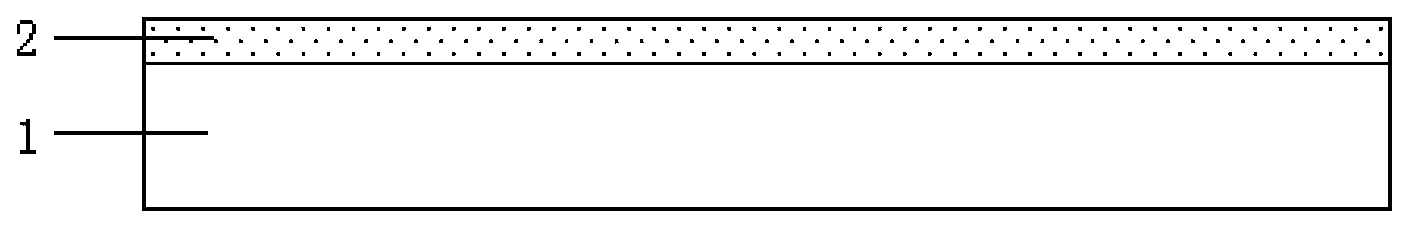

[0031] 1) On the silicon substrate 1, a tunnel oxide layer 2 with a thickness of 10 angstroms to 40 angstroms is prepared through the RadOx oxidation process (such as figure 1 shown);

[0032] Wherein, the process parameter of RadOx oxidation process is H 2 :1slm~30slm, O 2 : 1slm~100slm, the reaction temperature is 900~1200°C, and the pressure is 0~25torr.

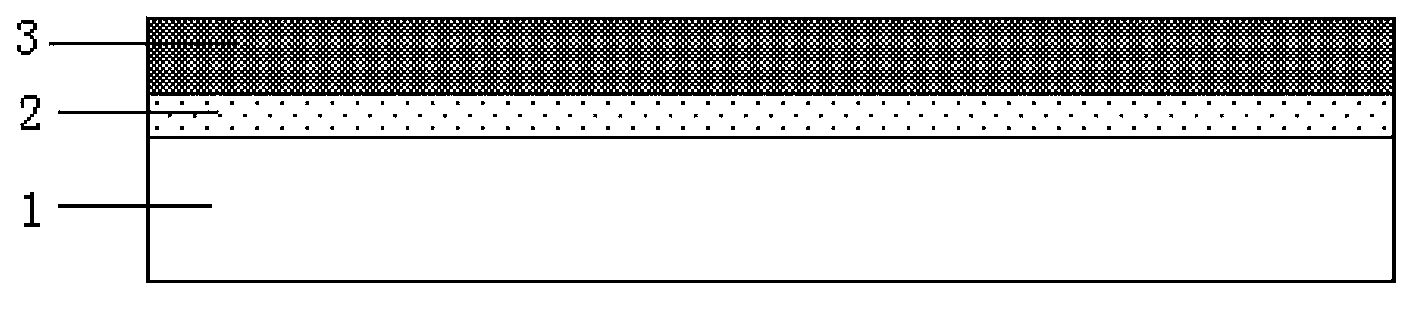

[0033] 2) On the tunnel oxide layer 2, a silicon nitride layer 3 with a thickness of 20 angstroms to 60 angstroms (eg figure 2 shown);

[0034] Wherein, the technological parameter of chemical vapor deposition method is as follows:

[0035] Flow is NH 3 :30sccm~100sccm, SiH 2 Cl 2 : 50sccm~120sccm, the reaction temperature is 700~760°C, and the pressure is 150~300mtorr.

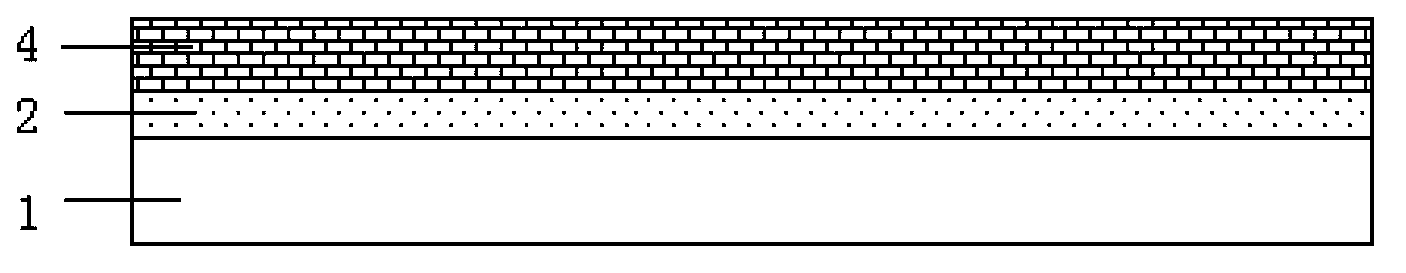

[0036] 3) Using the RadOx oxidation process, perform ISSG oxidation on the silicon nitride layer 3 to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com