Electrically programmable metal fuse device structure

A metal fuse and device structure technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of smaller fuse cross-sectional area, difficult fuse blowing, unsatisfactory blowing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

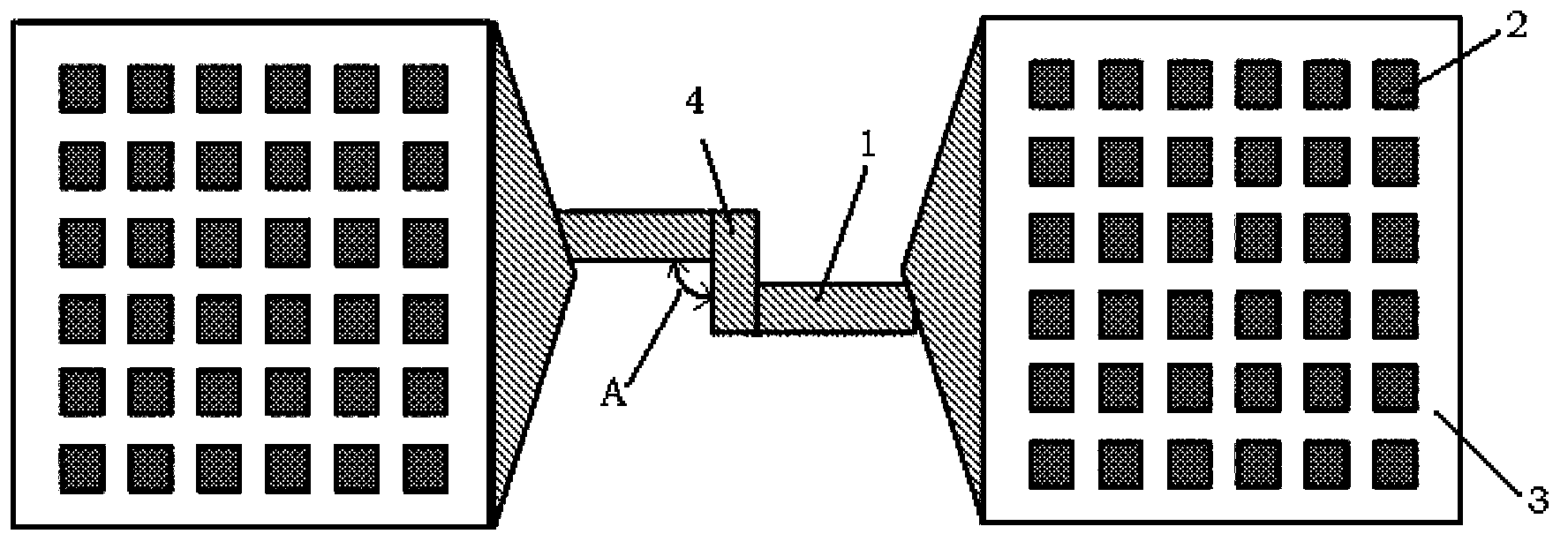

[0017] Such as figure 1 As shown, an embodiment of the present invention includes: a metal layer 3 having a contact hole 2, a metal fuse 1 connected between the two metal layers 3, wherein the metal fuse 1 has a serpentine corner 4, The angle A of the serpentine knuckle 4 is equal to 90 degrees.

[0018] The present invention has been described in detail through specific implementations and examples above, but these are not intended to limit the present invention. Without departing from the principle of the present invention, those skilled in the art can also make many modifications and improvements, which should also be regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com