Motor control apparatus

A technology for control devices and motors, applied in motor control, AC motor control, control systems, etc., can solve the problems of inability to shorten positioning adjustment time, fail to ensure stability, and consume time, and achieve shortened positioning adjustment time and interference suppression performance The effect of improving and shortening the positioning adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] [Configuration of the motor controller]

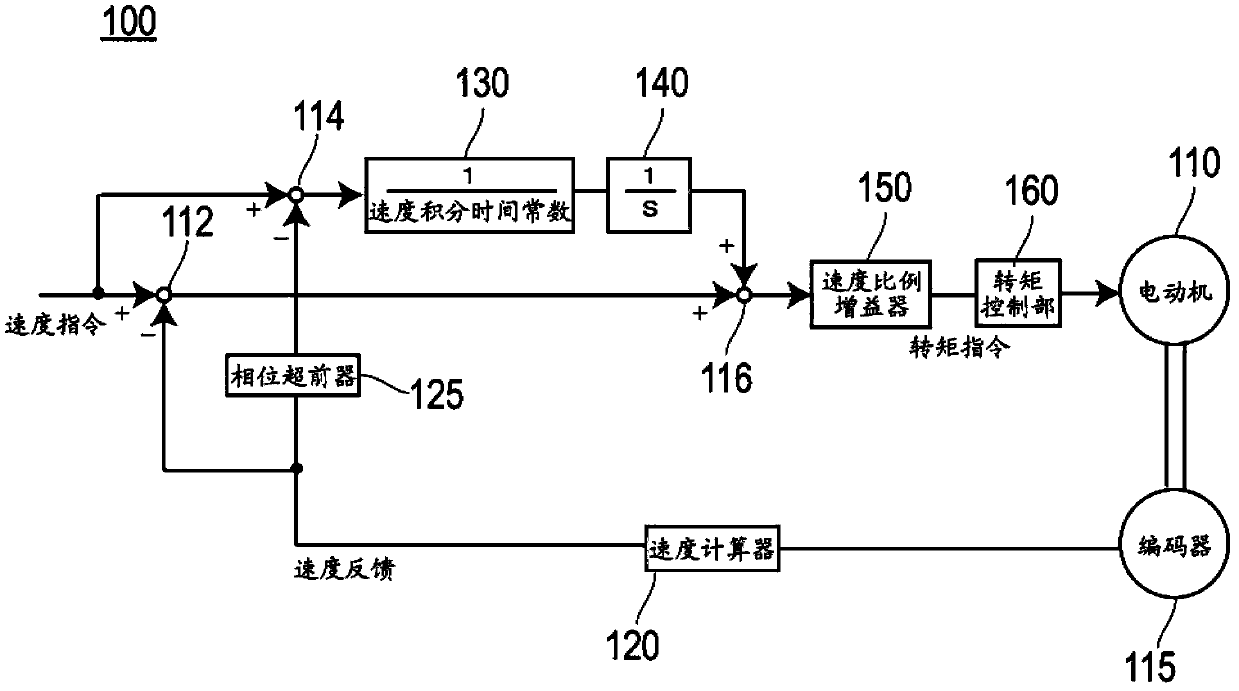

[0036] figure 1 It is a configuration diagram of the speed control system of the motor control device according to Embodiment 1. As shown in the figure, motor control device 100 according to Embodiment 1 includes phase advancer 125 , speed integral time constant adder 130 , integrator 140 , speed proportional gainer 150 , and torque control unit 160 .

[0037] The phase advancer 125 advances the phase of the speed feedback calculated by the speed calculator 120 by a set amount. For example, the phase of the speed feedback is advanced by a time equivalent to the hysteresis of the speed control system. The transfer function of the phase advancer 125 is preferably (1+ST2) / (1+ST1). However, the magnitude relationship between T1 and T2 in this case is T1<T2.

[0038] Also, the speed calculator 120 calculates a speed feedback based on the rotational position of the motor 110 detected by the encoder 115 .

[0039] The speed integr...

Embodiment approach 2

[0060] [Configuration of the motor controller]

[0061] Figure 5 It is a configuration diagram of a motor control device according to Embodiment 2. As shown in the figure, motor control device 200 according to Embodiment 2 includes position proportional gainer 220 , speed calculator 230 , speed control unit 240 , and torque control unit 250 .

[0062] The position proportional gainer 220 multiplies the position deviation obtained by subtracting the position feedback output from the encoder 215 from the position command at the accumulation point 212 by a proportional gain KP to output a speed command.

[0063] The speed calculator 230 is input with the position feedback output from the encoder 215, and calculates the speed feedback.

[0064] The speed control section 240 has the figure 1 The speed control system (phase advancer 125 , speed integral time constant adder 130 , integrator 140 , speed proportional gainer 150 ) of the motor control device 100 shown has the same c...

Embodiment approach 3

[0080] [Configuration of the motor controller]

[0081] Figure 8 It is a configuration diagram of a speed control system of a motor control device according to Embodiment 3. As shown in the figure, a motor control device 300 according to Embodiment 3 includes a phase advancer 325, a speed integral compensation low-pass filter 330, a speed integral time constant adder 340, an integrator 350, a speed proportional gainer 360, and a torque control Section 370.

[0082] The motor control device 300 according to Embodiment 3 differs from the motor control device 100 according to Embodiment 1 only in that it includes a speed integral compensation low-pass filter 330 , and the other configurations are the same. The speed control system of the motor control device 330 according to the third embodiment can also be applied to the speed control unit 240 of the motor control device 200 according to the second embodiment.

[0083] In addition, the respective functions of the phase advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com