A special equipment for processing chaff mixture

A special equipment and mixture technology, which is used in grain processing, application, and separation of solids from solids by air flow, etc., can solve the problem of not having the separation and recovery function of chaff mixture, unsatisfactory separation and recovery effect, and separation and recovery processing efficiency. Low problems, to achieve the effect of low degree of manual intervention, improved production environment, and low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

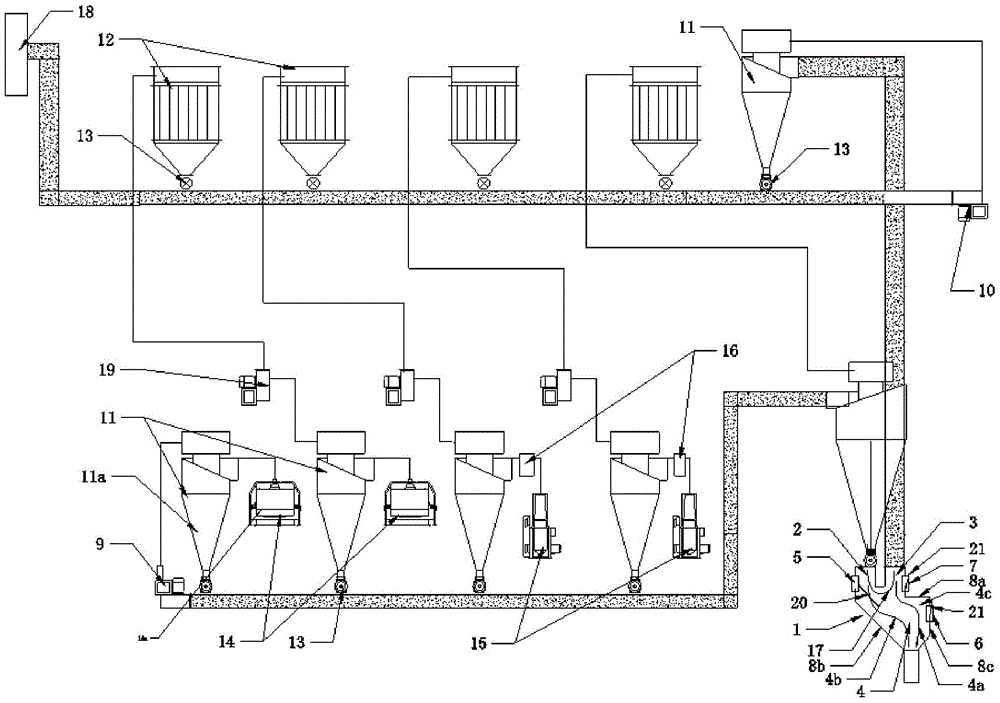

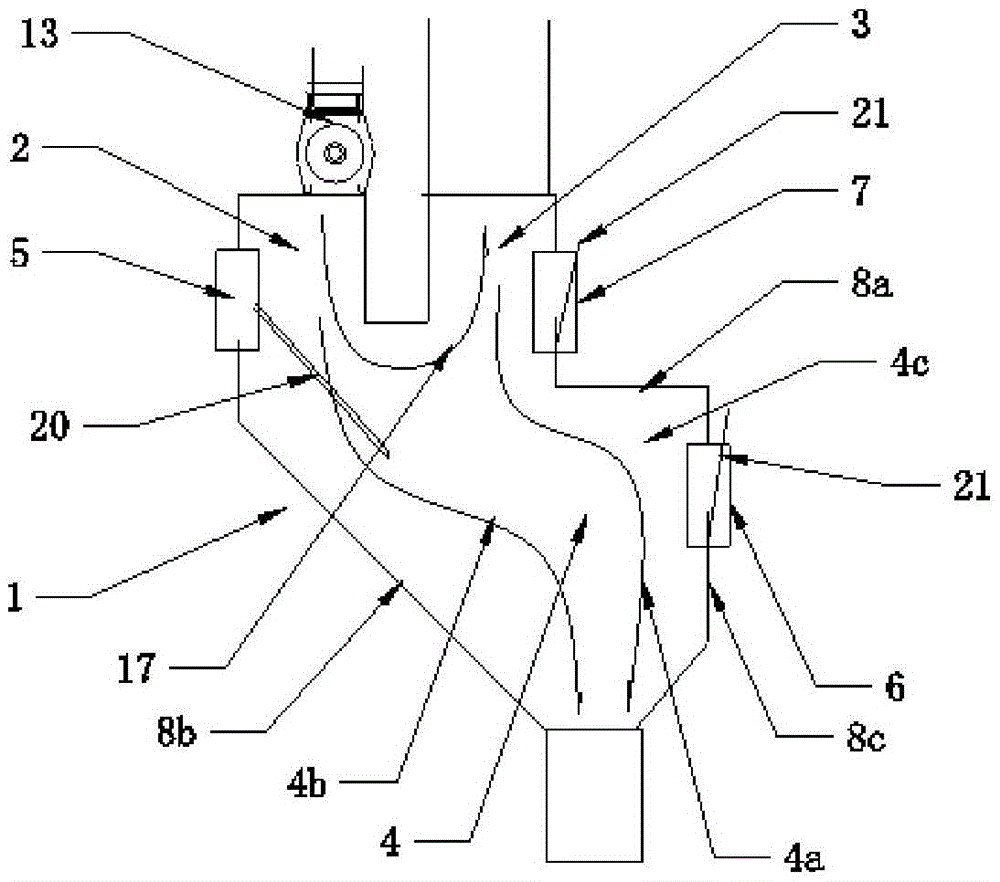

[0017] Such as figure 1 with 2 As shown, the special equipment for the processing of the chaff mixture of the present embodiment includes a rice processing system and a separation processing system, and the processing system includes multiple (also one) vibrating cleaning screens 14 and multiple ( It can also be one) a rice huller 15 as a rice huller, the separation treatment system includes a special-shaped separation chamber 1, and the special-shaped separation chamber 1 is connected to the processing system and the dust collection system respectively, and the dust collection system includes corresponding to the processing system respectively. A plurality of pulse bag filter 12 corresponding to the rice huller and impurity remover.

[0018] The special-shaped sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com