The magnetic pole of the special universal grinding machine for nuclear power bearing ring processing

A technology for bearing rings and universal grinding machines, which is applied to the parts of grinding machine tools, grinding machines, metal processing equipment, etc., and can solve problems such as easy stop and influence of workpiece positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

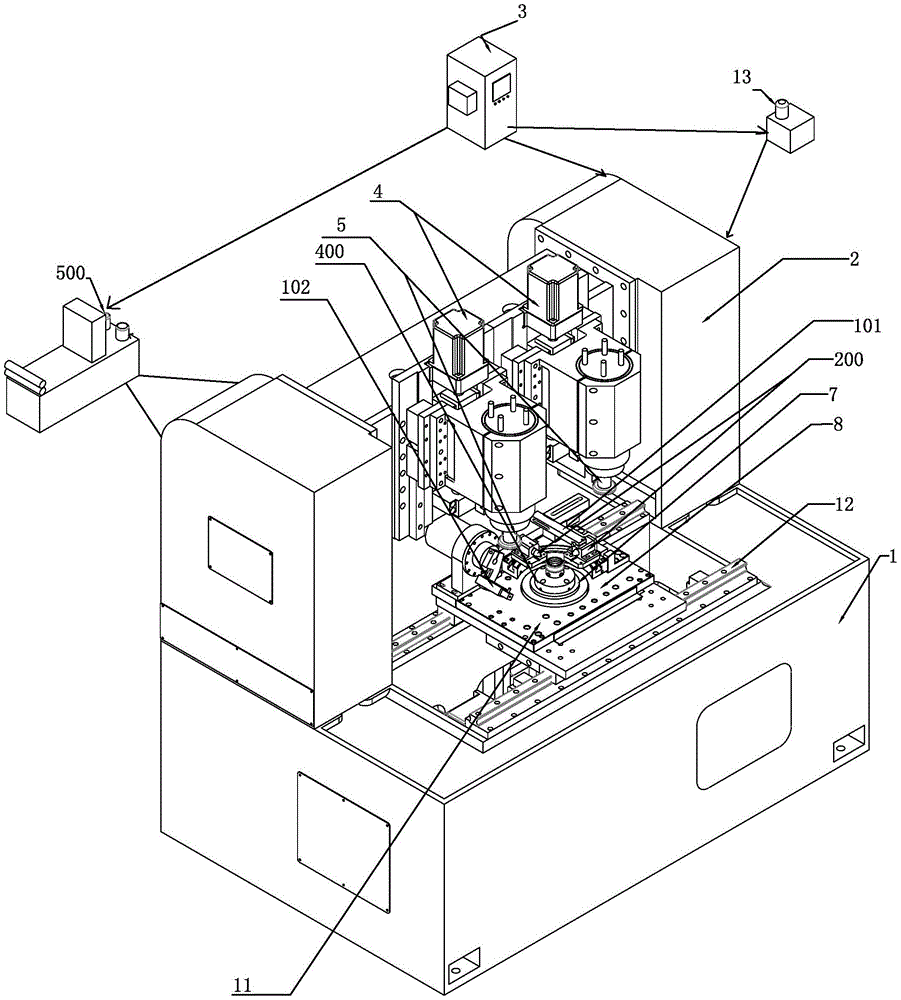

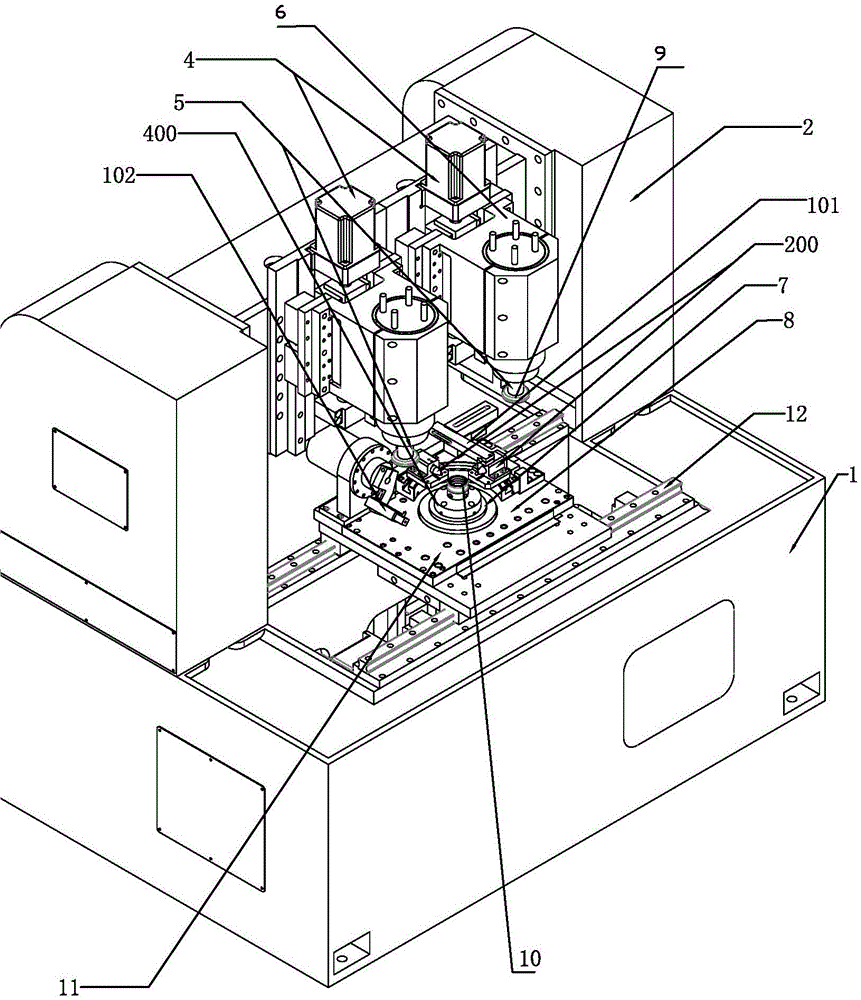

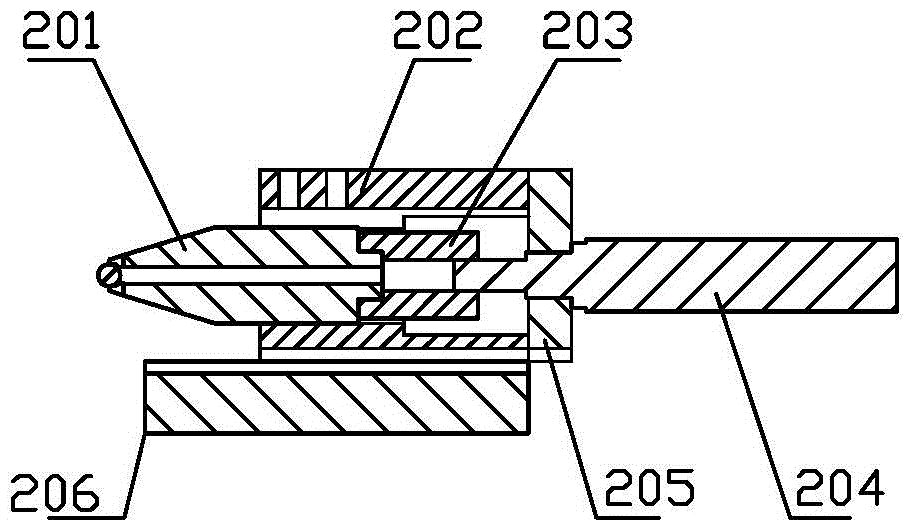

[0041] A magnetic pole of a special universal grinder for nuclear power bearing ring processing, installed on the special universal grinder for nuclear power bearing ring processing, the magnetic pole 400 includes a magnetic pole base 401, a workpiece support part 402, a chip removal hole 403, and an upper annular end face 404 There are 2-4 chip removal holes 403, which are arranged in the middle of the side wall of the workpiece support part 402, and the central hole of the magnetic pole 400 is connected to the workpiece shaft 7; the workpiece translation mechanism 8 is the console, which moves in the horizontal direction to drive the workpiece to the processing position corresponding position;

[0042] The special universal grinding machine for nuclear power bearing ring processing also includes a machine base 1, a bed 2, a hydraulic system 13, an electric control system 3, a servo system 4, an electric spindle 5, a spindle lifting mechanism 6, a workpiece shaft 7, and a grin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap