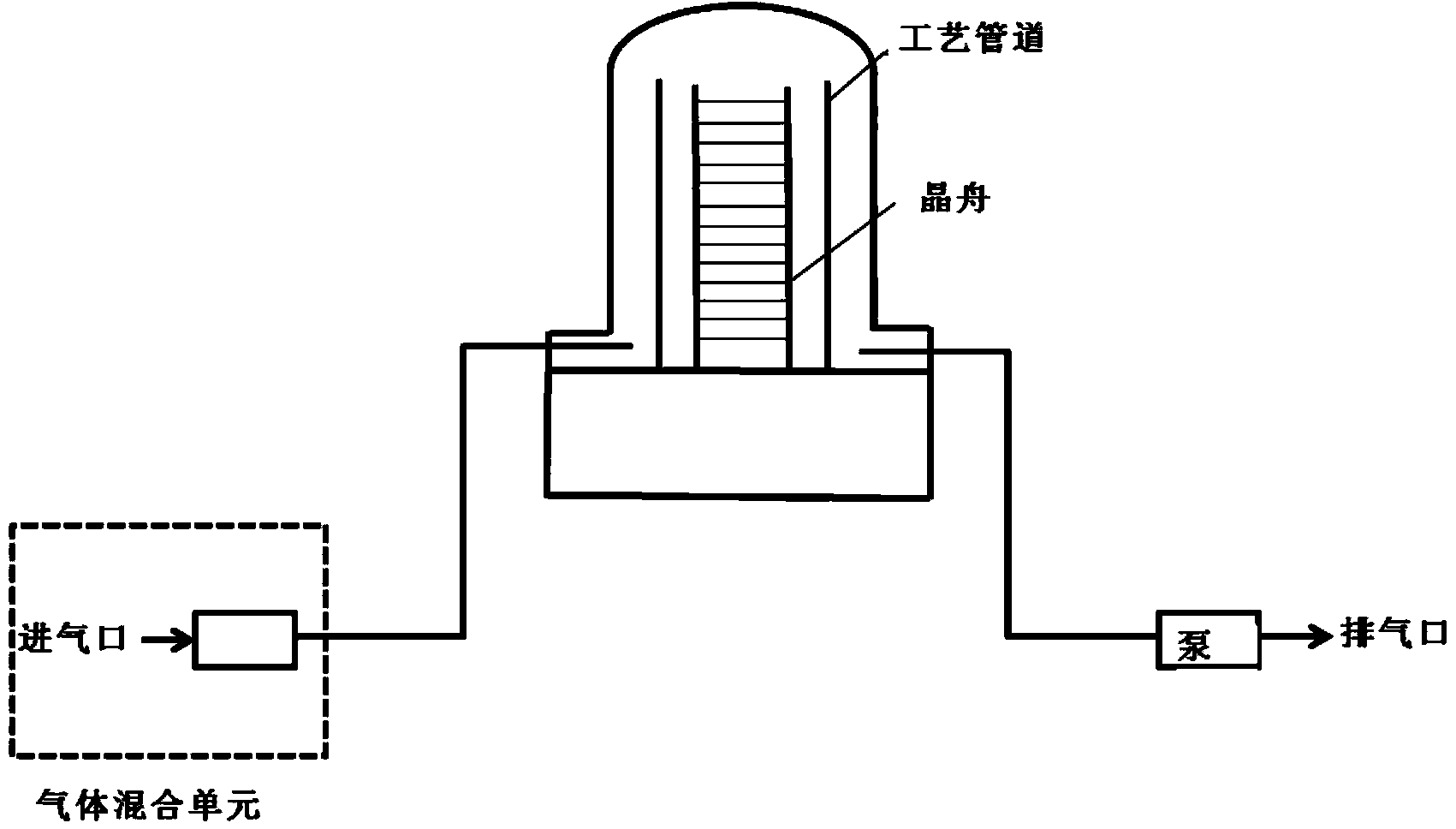

Method for decreasing impurity particles in low pressure furnace tube

A low-pressure furnace and impurity technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of higher requirements for equipment and processes, more clean gases, and unfavorable cleaning methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

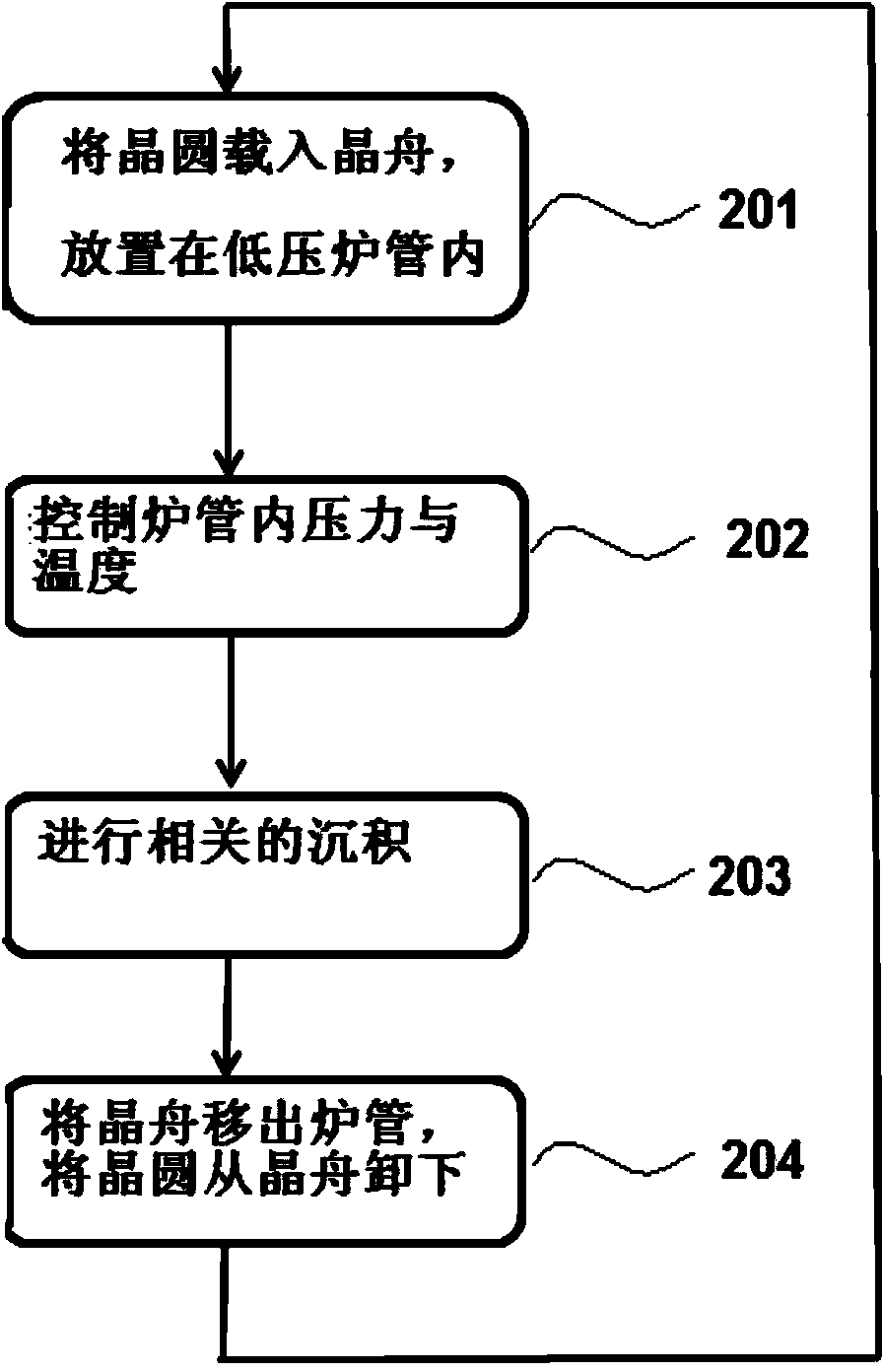

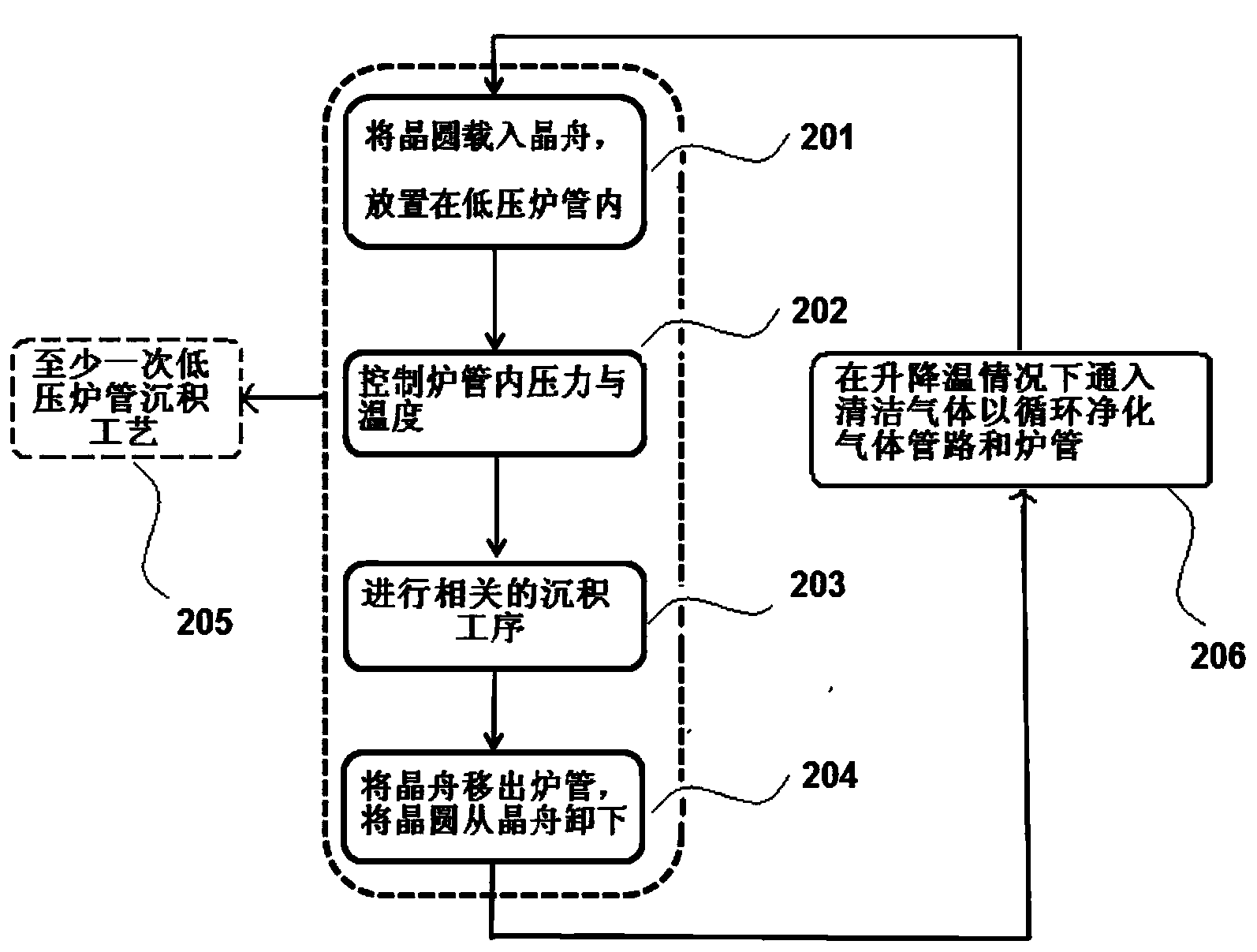

Method used

Image

Examples

Embodiment Construction

[0032] The present invention adopts the method of raising and lowering the temperature of the low-pressure furnace tube after completing at least one operation of the low-pressure furnace tube, and by controlling the temperature of the low-pressure furnace tube, the rate of temperature rise and fall, and the type of gas, and according to a certain interval time and cleaning time, a constant pressure is introduced. The method of cleaning the gas to achieve the purpose of improving the particle condition of the low-pressure furnace tube, thereby reducing the impurity particles generated during the process of the low-pressure furnace tube, especially reducing the impurity particles on the inner wall of the furnace tube, so that the wafer control wafers produced The impurity particles are reduced by at least 10.

[0033] The inventors have found through research that the main methods of cleaning gas in the prior art to remove impurity particles in the reaction chamber can be divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com