Continuous fiber reinforced polyolefin composite tube and preparation technology thereof

A technology of continuous fiber and preparation process, applied in the field of continuous fiber reinforced polyolefin composite pipe and its preparation process, can solve the problems of inconvenient transportation, corrosion, susceptibility to pressure fluctuations, etc., achieve convenient use and transportation, increase compressive strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

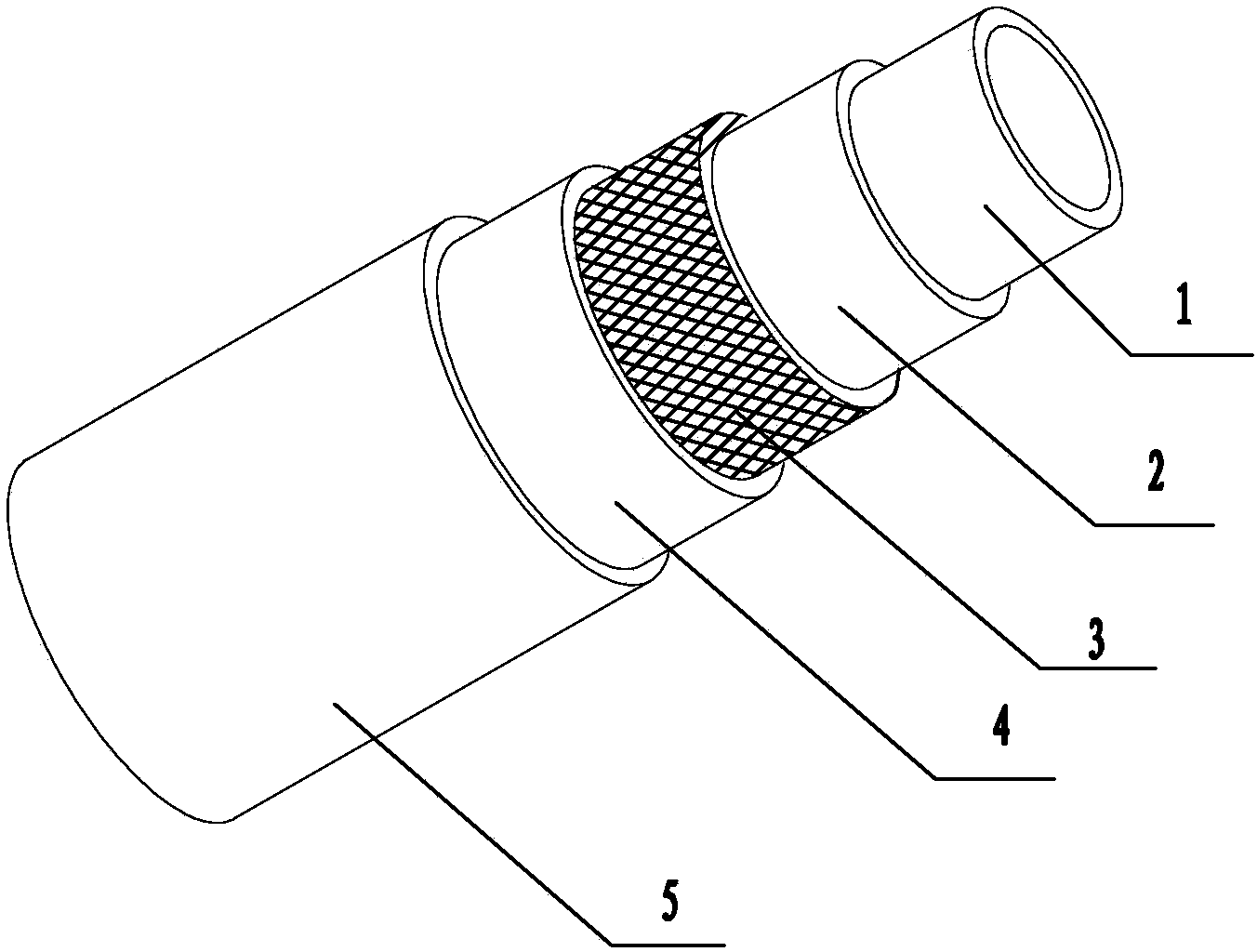

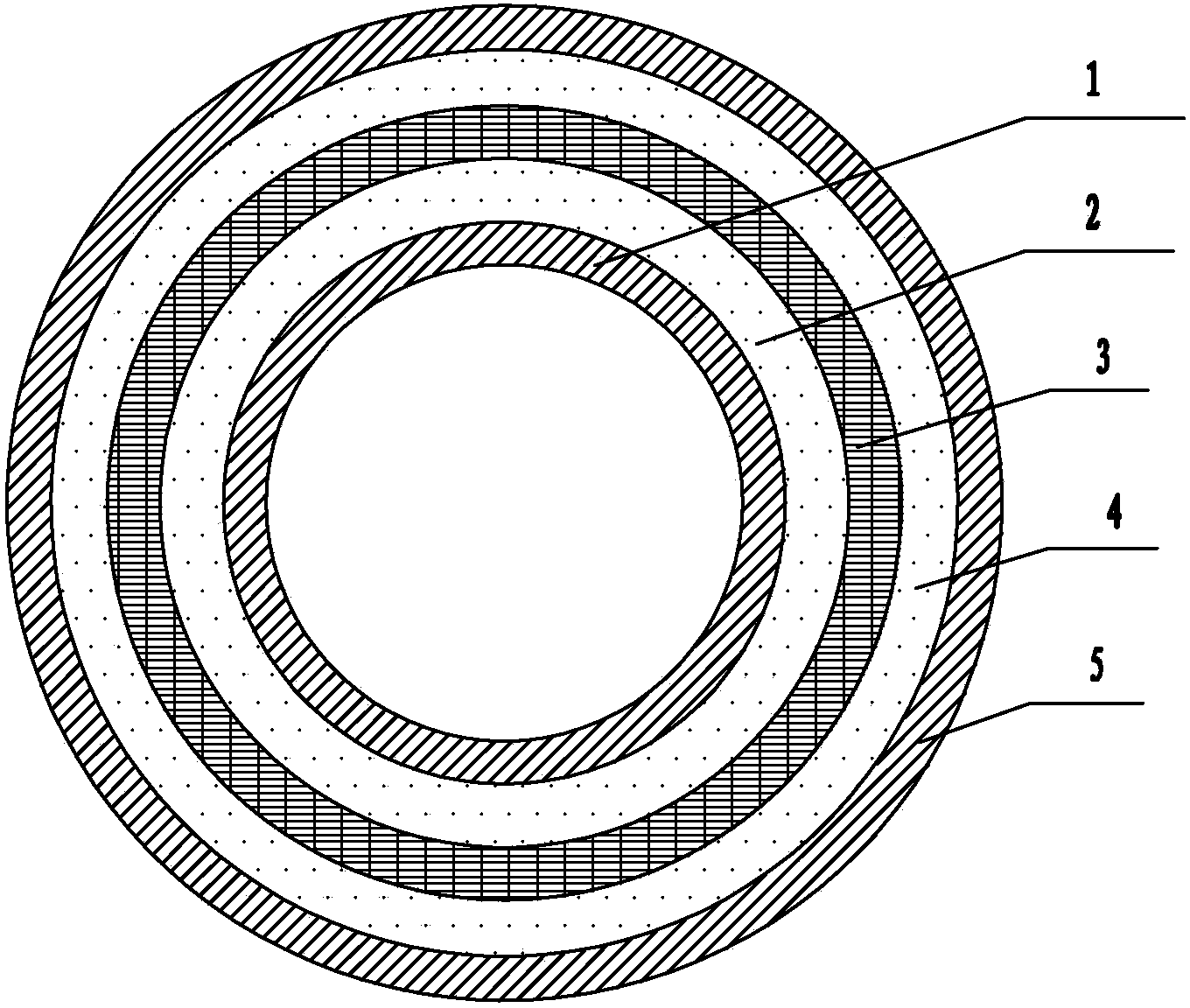

[0030] The continuous fiber reinforced polyolefin composite pipe of the present invention comprises an inner plastic pipe 1, an inner hot melt adhesive layer 2 is arranged outside the inner layer plastic pipe 1, and a continuous fiber impregnated belt 3 is arranged on the inner hot melt adhesive layer 2, and the continuous fiber impregnated The belt 3 is provided with an outer hot-melt adhesive layer 4, and an outer plastic tube 5 is arranged outside the outer hot-melt adhesive layer 4.

[0031] The continuous fiber impregnated belt 3 is made of impregnated glass fibers cross-helically wound.

[0032] The preparation process of the continuous fiber reinforced polyolefin composite pipe is to coat the inner plastic pipe 1 with the inner hot melt adhesive layer 2, then preheat the continuous fiber impregnated tape 3 and wrap it around the inner plastic pipe 1, and then coat the outer hot melt adhesive Layer 4, and finally wrap a layer of outer plastic pipe 5 on the outer layer to...

Embodiment 2

[0041] This example has the same product structure and preparation process as Example 1, except that the continuous fiber impregnated tape 3 is prepared by co-extruding 60% glass fiber and 40% polyolefin at 200°C, calendering and drawing A continuous fiber impregnated tape 3 was obtained.

[0042] The polyolefin is LLDPE.

[0043] Both the inner hot melt adhesive layer 2 and the outer hot melt adhesive layer 4 are maleic anhydride grafted polypropylene.

[0044] Both the inner layer plastic pipe 1 and the outer layer plastic pipe 5 are polypropylene with flame retardant and antistatic treatment.

[0045] The preheating temperature of the continuous fiber impregnated belt is 220°C, and the preheating time is 1 minute.

[0046] The heating temperature of the whole composite pipe is 220° C., and the heating time is 5 minutes.

[0047] The traction speed is 20r / min; the rolling speed is 18r / min.

Embodiment 3

[0049] The product structure and preparation process of this example are the same as those of Example 1, the difference is that the continuous fiber impregnated tape 3 is prepared by co-extruding 75% glass fiber and 25% polyolefin at 170°C, calendering and pulling A continuous fiber impregnated tape 3 was obtained.

[0050] Polyolefin is IPC.

[0051] Both the inner hot melt adhesive layer 2 and the outer hot melt adhesive layer 4 are maleic anhydride grafted polypropylene.

[0052] Both the inner layer plastic pipe 1 and the outer layer plastic pipe 5 are polypropylene with flame retardant and antistatic treatment.

[0053] The preheating temperature of the continuous fiber impregnated belt is 180°C, and the preheating time is 2 minutes.

[0054] The heating temperature of the whole composite tube is 240° C., and the heating time is 3 minutes.

[0055] The traction speed is 28r / min; the rolling speed is 22r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com