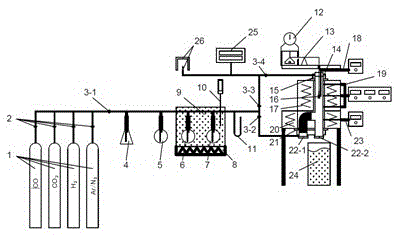

Experimental method and device for gas-based reduction and slagging process of iron-containing raw materials

A technology of iron-containing raw materials and experimental equipment, applied in the direction of weighing by removing certain components, can solve problems such as inconvenient operation, inability to meet the requirements of process detection and later sampling, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: an experimental method for gas-based reduction and slagging process of iron-containing raw materials, comprising the following steps:

[0048] 1) Take 100 g of ferric oxide pure reagent (purity greater than 99%), grind it to below 200 mesh, then take out 5 g of it and place it in a mold, and press it under a pressure of 20 MPa to make a diameter of the bottom surface of 15 mm and a thickness of 5 mm. mm cylindrical block;

[0049] 2) Place the sample in a hanging basket made of molybdenum wire, and hang it in the middle of the reaction furnace through the metal molybdenum wire. The total weight is 25 g), and it is connected to the secondary electronic balance, and the upper sealing cover and the two lower sealing covers of the reaction tube are covered;

[0050] 3) Open the nitrogen valve, empty the air in the reaction tube, turn on the power supply of the reaction furnace and the preheating furnace at the same time, and set the target temperature of both...

Embodiment 2

[0059] Embodiment 2: adopting above-mentioned device to carry out gas-based reduction of iron-containing raw material, the experimental method of slagging process, comprises the following steps:

[0060] 1) ~ 5) with embodiment 1;

[0061] 6) After the reduction degree of the sample reaches 50%, set the target temperature of the reaction furnace to 1200°C, and the heating rate is 10°C / min;

[0062] 7) After reaching 1200°C, further keep the temperature constant for 60 minutes;

[0063] 8) After 60 minutes, close the carbon monoxide valve, record the final reduction level of the sample, put the aqueous sample collection tank under the reaction tube, open the lower sealing cover of the reaction tube at the same time, remove the hanger from the primary balance The metal molybdenum wire of the sample allows the sample to fall into the sample collection tank under the action of gravity;

[0064] 9) Analyze the slagging characteristics (morphological distribution, phase distributi...

Embodiment 3

[0065] Embodiment 3: adopting above-mentioned device to carry out gas-based reduction of iron-containing raw material, the experimental method of slagging process, comprises the following steps:

[0066] 1) Take 100 g of iron ore powder (Australian ore, Brazilian ore or domestic concentrate powder can be used), grind it to below 200 mesh, then take out 5 g of it and put it in the mold, press it under 20 MPa pressure to make the bottom diameter of 15 mm, cylindrical block with a thickness of 5 mm;

[0067] 2) Place the sample in a hanging basket made of molybdenum wire, and hang it in the middle of the reaction furnace through the metal molybdenum wire. The total weight is 25 g), and it is connected to the secondary electronic balance, and the upper sealing cover and the two lower sealing covers of the reaction tube are covered;

[0068] 3) Open the nitrogen valve, empty the air in the reaction tube, close the inlet and outlet valves of the reaction tube and open the straight-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com