Matrix load device

A load device and matrix technology, applied in the field of electrical testing equipment, can solve the problems of time-consuming and laborious, unretrieved patents, welding quality, and temperature and humidity factors are greatly affected, and achieve accurate test data, simple and practical device, and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

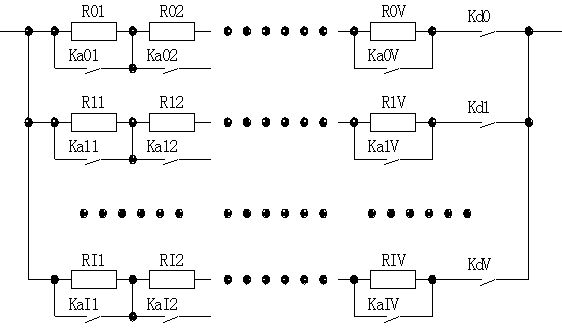

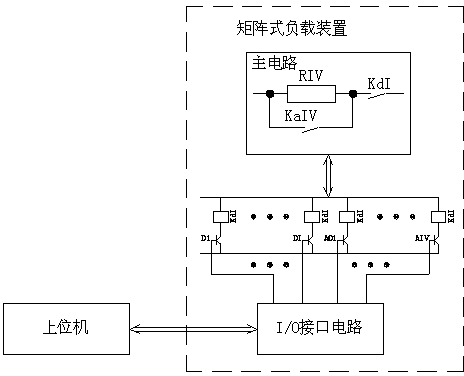

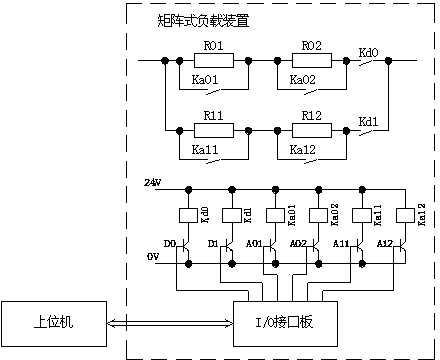

[0019] Example: such as Figure 1 to Figure 3 As shown, the matrix load device is composed of the connection of the main circuit and the control circuit;

[0020] The main circuit is composed of several branches connected in parallel; several high-precision impedances R are connected in series on each branch, and a row switch Ka is connected to both ends of each high-precision impedance R; a column switch Kd is connected in series at the end of each branch;

[0021] The high-precision impedance matrix RIV composed of high-precision impedance R, the row switch Ka, and the column switch Kd form the main circuit;

[0022] The control circuit is composed of an I / O interface circuit and a switch drive circuit; the switch drive circuit is composed of a transistor, a capacitor element or a relay;

[0023] The I / O interface circuit is composed of single-chip microcomputer or DSP (depending on the number of array combinations of the specific product to determine the model)...

Embodiment approach

[0037] Best practice includes: mounting the entire impedance array in a fan forced air cabinet;

[0038] The selection switch K and the control circuit are installed in a place where the heat of the array impedance is not affected (small);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com