Method for improving photoetching process used on Al2O3 medium

A photolithography process and dielectric layer technology, which is used in photosensitive material processing, microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems affecting device performance, small process tolerance, high price, etc. Stable, small process tolerances and high repetition rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

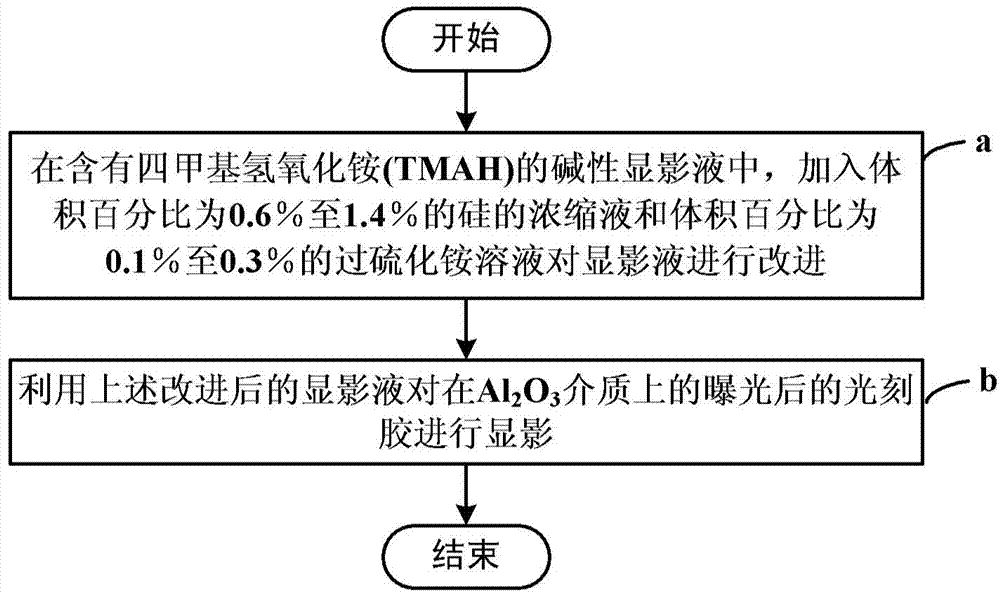

[0028] Example 1: Al photoetched based on AZ4620 photoresist 2 o 3 Medium layer, the specific steps are as follows:

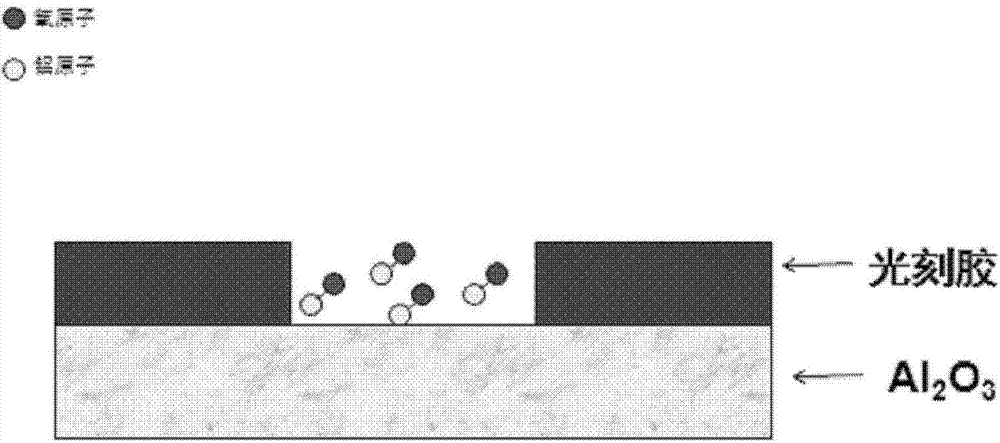

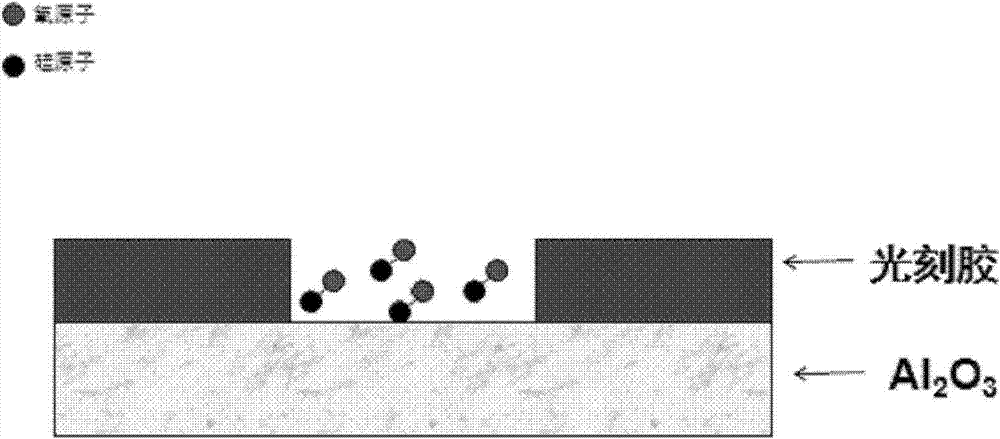

[0029] Step 1: In the alkaline developer solution containing tetramethylammonium hydroxide, add the concentrated solution of silicon (Si) with a volume percentage of about 1% and ammonium persulfide ((NH) with a volume percentage of about 0.2% 4 ) 2 S 2 o 8 ) solution;

[0030] Step 2: Use the above-mentioned improved developer solution on Al 2 o 3 The exposed photoresist on the dielectric layer is developed.

Embodiment 2

[0031] Embodiment 2: Al photoetched based on AZ5214 photoresist 2 o 3 medium layer, the specific steps are as follows.

[0032] Step 1: In the alkaline developer solution containing tetramethylammonium hydroxide, add the concentrated solution of silicon (Si) with a volume percentage of about 1% and ammonium persulfide ((NH) with a volume percentage of about 0.2% 4 ) 2 S 2 o 8 ) solution;

[0033] Step 2: Use the above-mentioned improved developer solution on Al 2 o 3 The exposed photoresist on the dielectric layer is developed.

Embodiment 3

[0034] Embodiment 3: Al photoetched based on AZ6112 photoresist 2 o 3Medium layer, the specific steps are as follows:

[0035] Step 1: In the alkaline developer solution containing tetramethylammonium hydroxide, add the concentrated solution of silicon (Si) with a volume percentage of about 1% and ammonium persulfide ((NH) with a volume percentage of about 0.2% 4 ) 2 S 2 o 8 ) solution;

[0036] Step 2: Use the above-mentioned improved developer solution on Al 2 o 3 The exposed photoresist on the dielectric layer is developed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com