Method for improving uniformity of oxide layer on surface of amorphous silicon

A technology of surface oxidation and amorphous silicon, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as difficult control of uniformity, and achieve the effect of improving uniformity and buffering energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

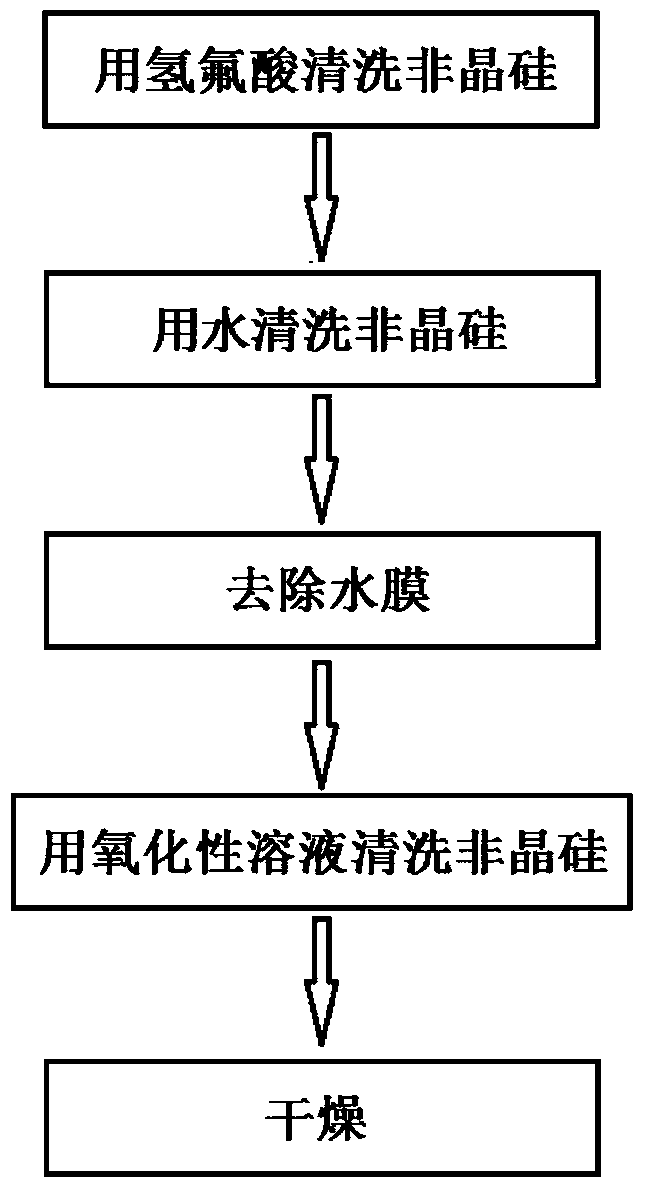

[0038] At room temperature, use a hydrofluoric acid solution with a concentration of 0.5% to clean the amorphous silicon wafer for 40 seconds to etch and remove the uneven oxide layer on the surface of the amorphous silicon; Hydrofluoric acid on the surface of the silicon wafer; after water cleaning, the water remaining on the surface of the silicon wafer will form a water film, use clean N 2 Dry the silicon wafer to remove the water film on the surface of the silicon wafer, N 2 The flow rate is 400NL / min, and the duration is 5s; then, use ozone water with a concentration of 15ppm to clean the silicon wafer for 40s to oxidize the silicon wafer, and use uniform techniques such as shaking and rotation to form a uniform Oxide layer; finally, the silicon wafer is spin-dried, and the rotating speed is kept at 300 rpm for 60 seconds. Since the interference of the water film is eliminated, after drying, a layer of uniform oxide layer is formed on the surface of the amorphous silicon....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com