Cooling system for electrical device

A technology of cooling system and electrical equipment, applied in the electrical field, can solve the problems of product cost burden, influence on the service life of components in the cabinet, etc., to achieve the effect of improving service life and reliability, saving product cost, and reducing working environment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

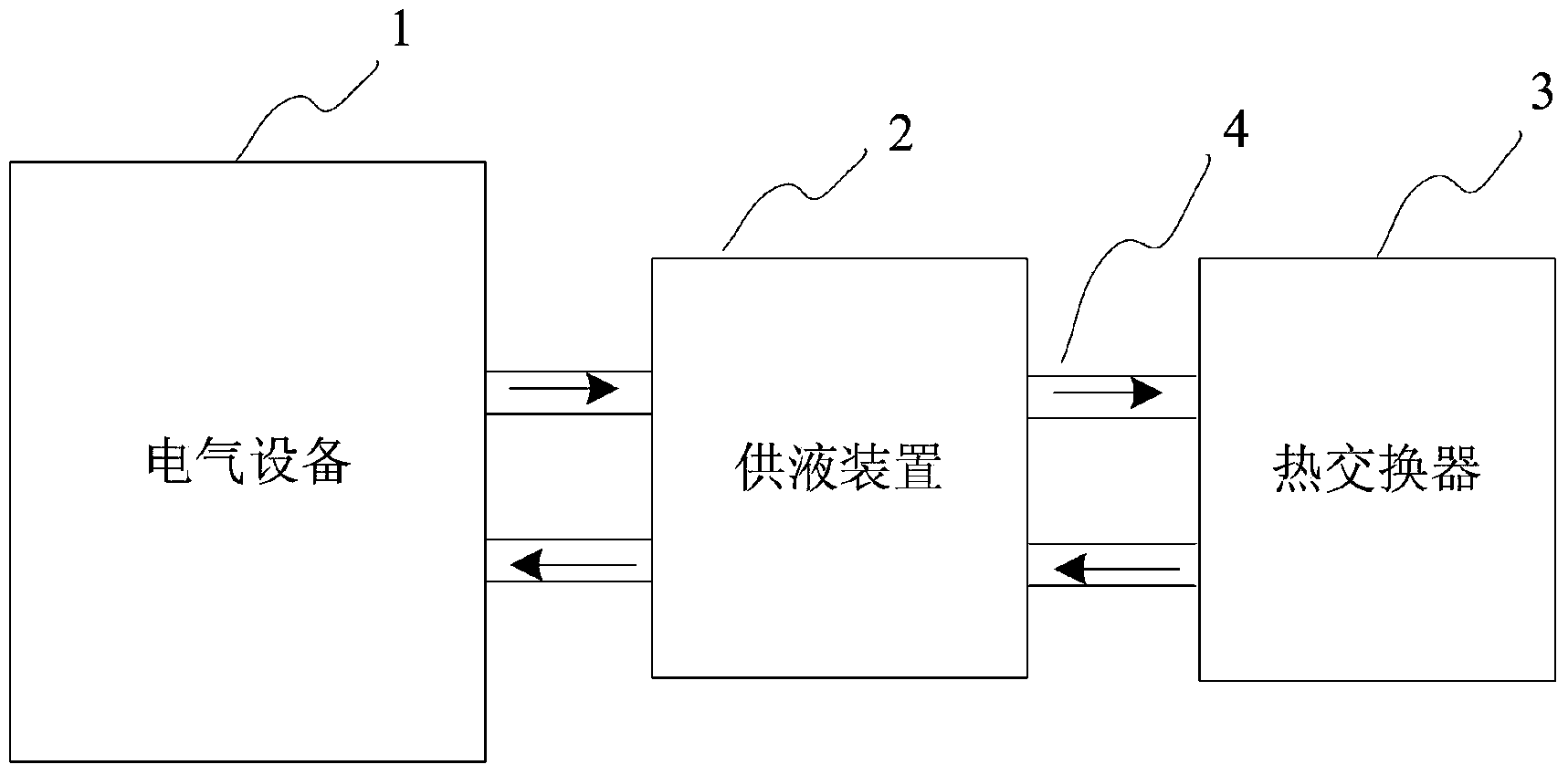

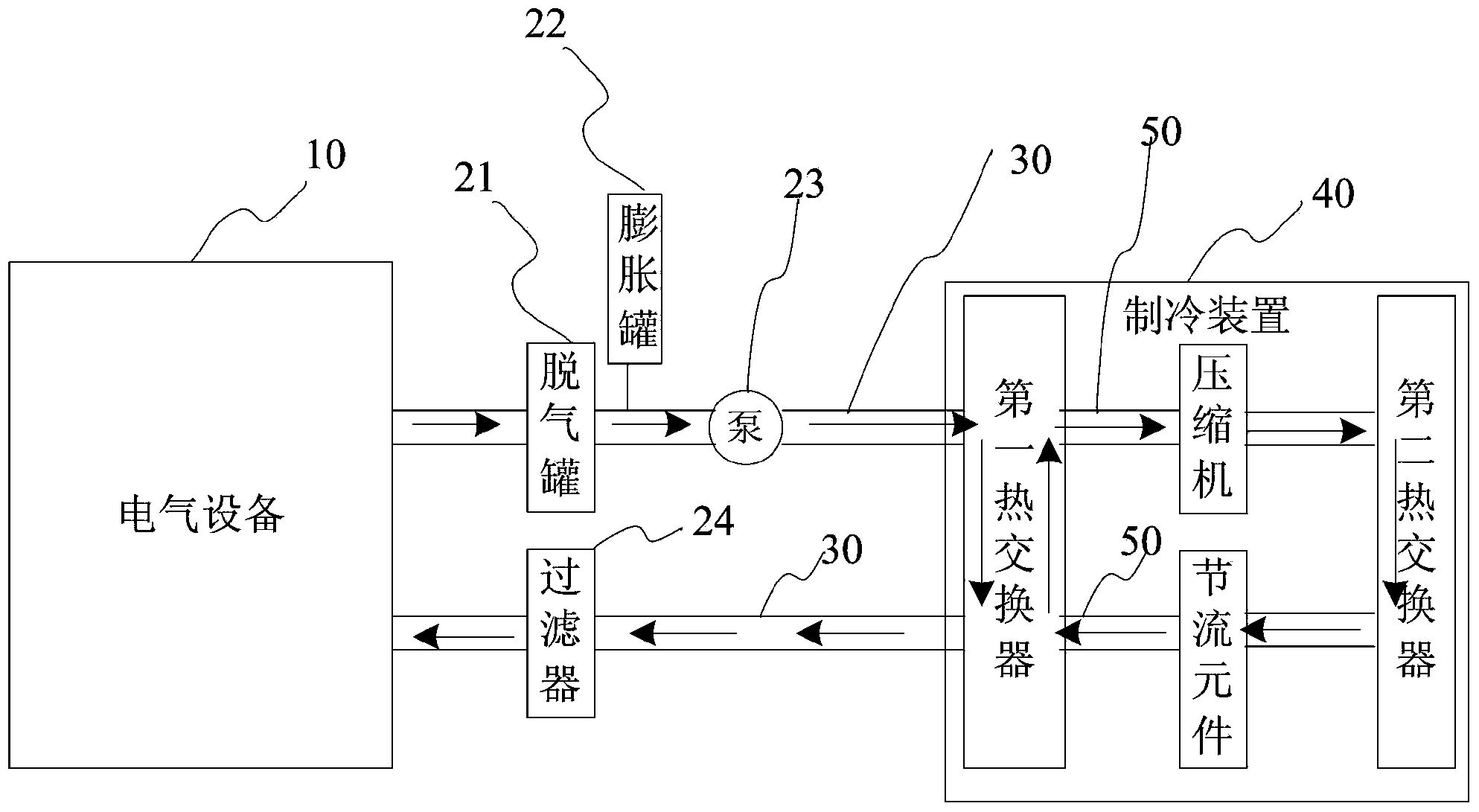

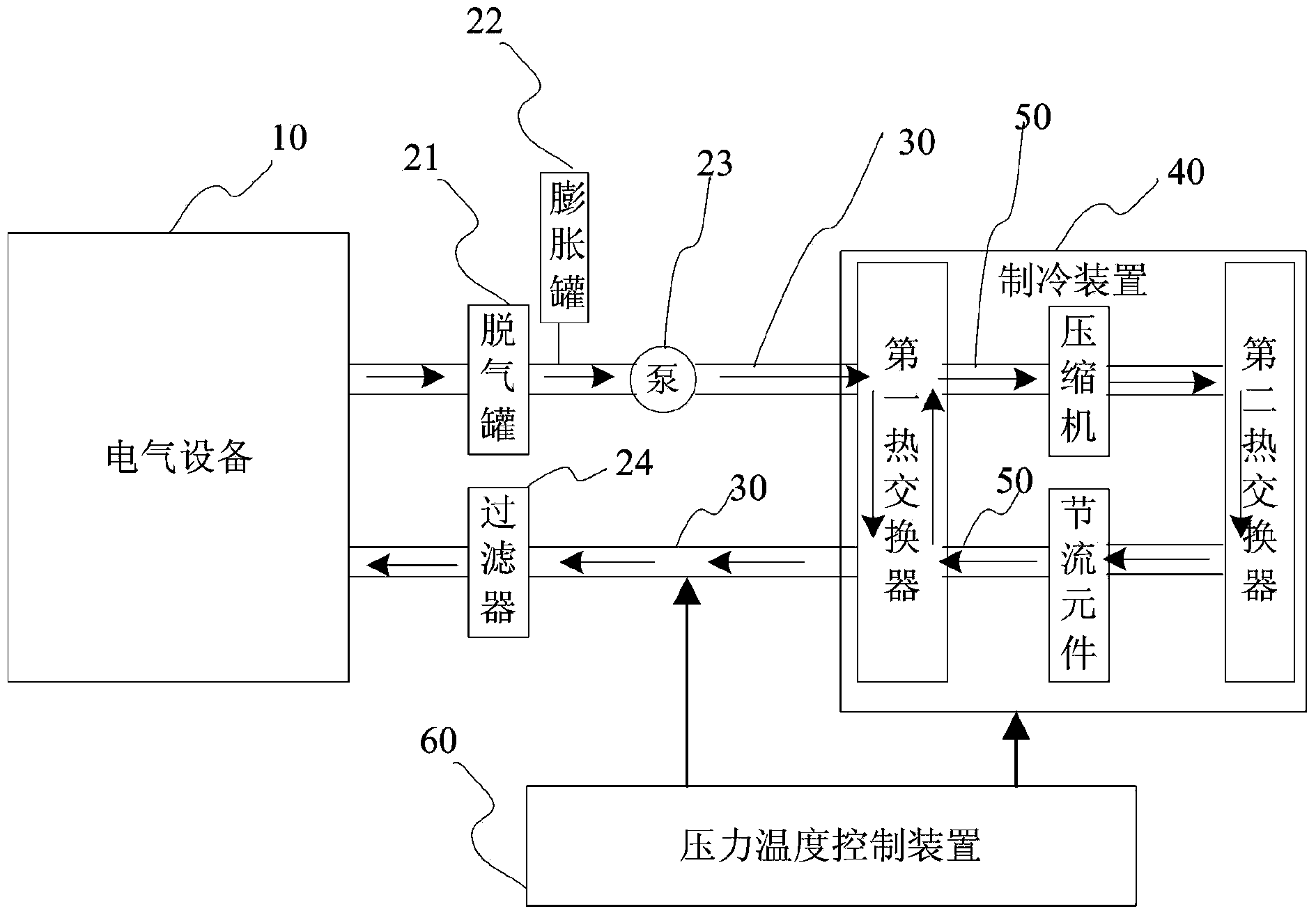

[0022] The principle of the cooling system of the electrical equipment of the preferred embodiment of the present invention is as follows: figure 2 and image 3 As shown, it includes electrical equipment 10 connected into a closed circuit through a first pipeline 30, a degassing tank 21, an expansion tank 22, a pump 23, a filter 24, and a refrigeration device 40; A first heat exchanger, a compressor, a second heat exchanger, and a throttling element connected in a closed circuit; a coolant is provided in the first pipeline 30 for exchanging heat with the electrical equipment 10; the second pipeline 50 Refrigerant is provided inside, and the refrigeration device 40 exchanges heat with the cooling liquid in the first pipeline 30 and the outside air through the refrigerant. In this way, heat is exchanged with the electrical equipment 10 through the cooling liquid first, and then the heat is exchanged with the cooling liquid in the first pipeline 30 and the outside air through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com