Multifunctional electric mini tiller

A micro-tiller and multi-functional technology, applied in the field of agricultural machinery and tools, can solve the problems of unfavorable land moisture conservation, water conservation, large energy consumption and waste, and high use cost, and achieve the goal of increasing agricultural production and income, saving production costs, and saving labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

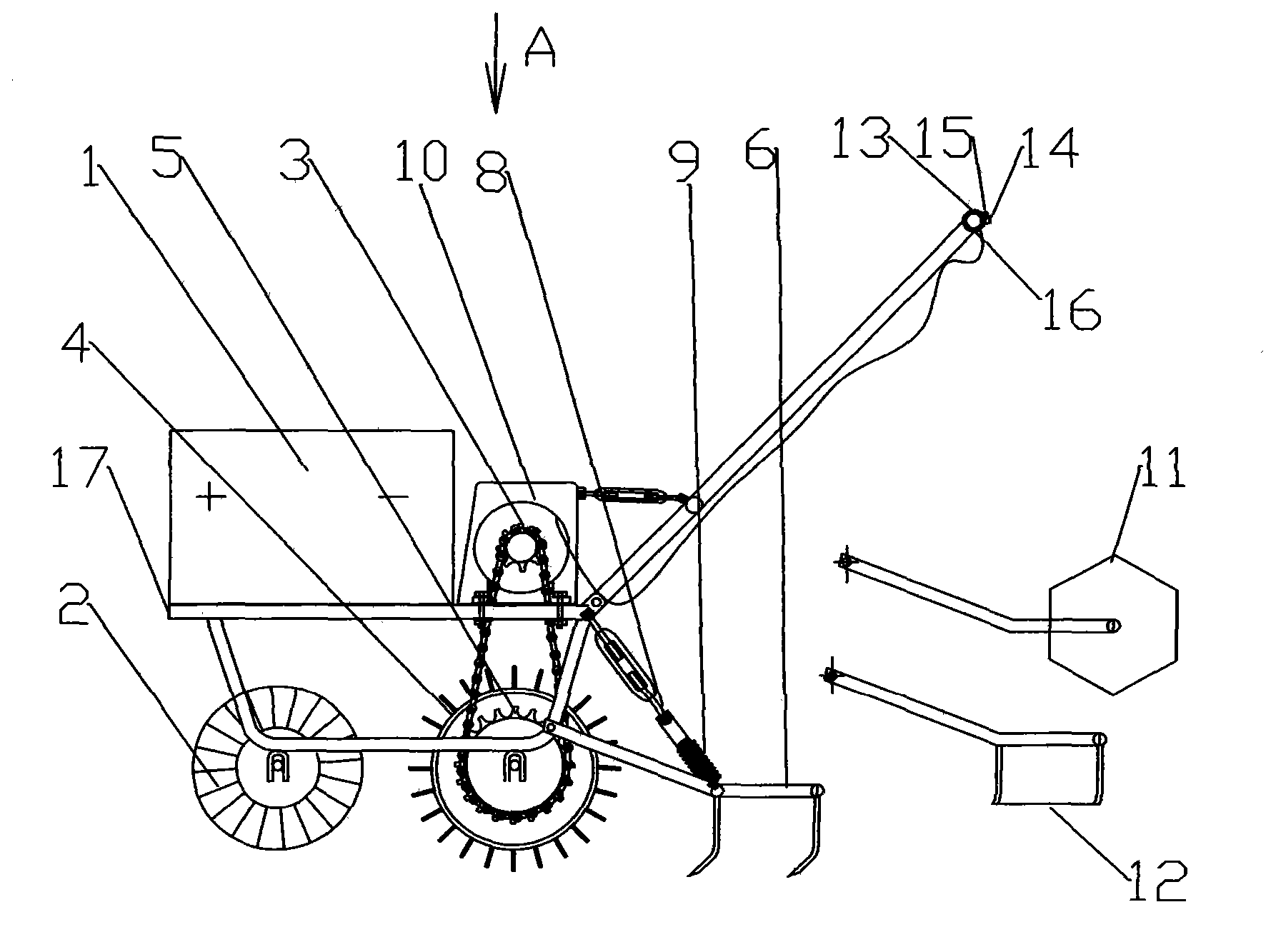

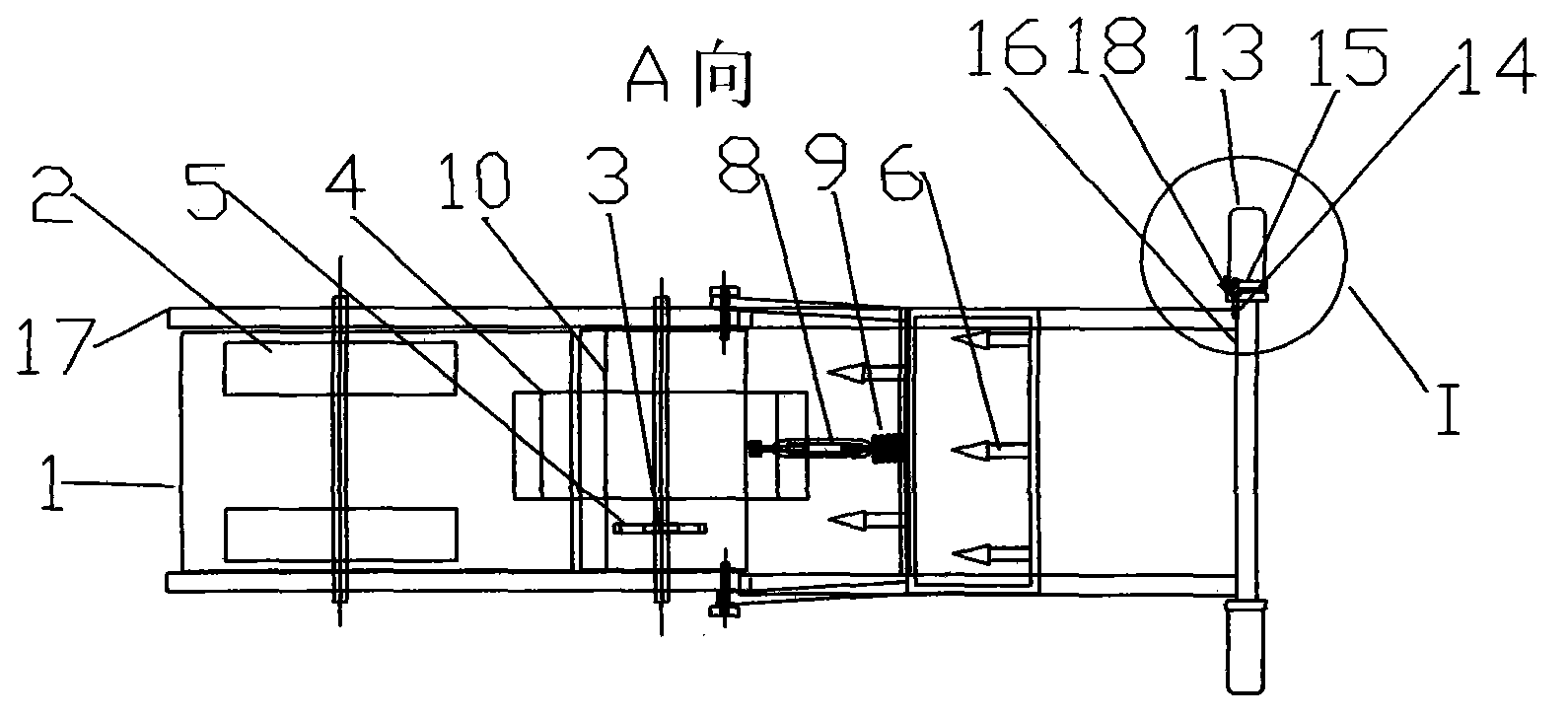

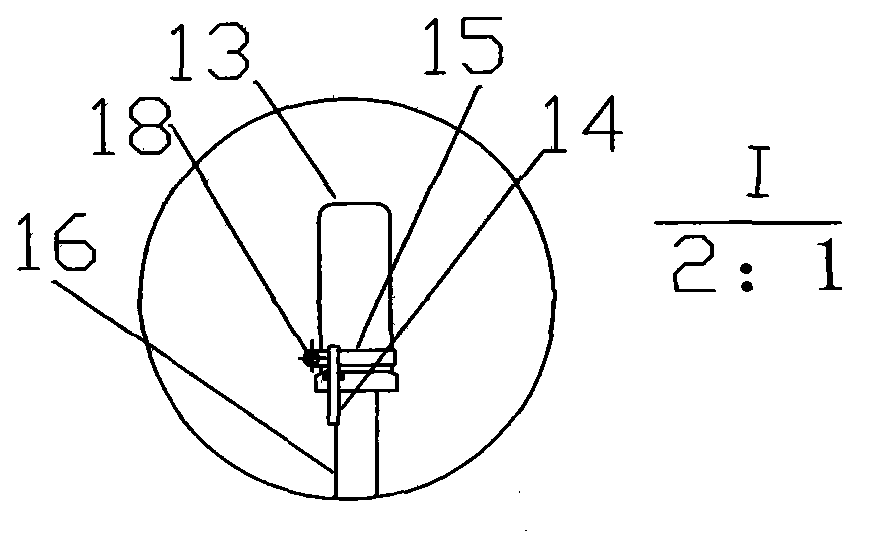

[0017] exist figure 1 , figure 2 , image 3 Among them, battery 1, motor 10, push handle 16, controller turn handle 13 are set on frame 17 top, plow share 6 is set on the right side of frame 17 bottoms, or pressure roller 11, or weeding knife 12; The 17 bottom is provided with non-operation traveling wheel 2 and operation driving wheel 4 at the same time, and operation driving wheel 4 is fixed with large sprocket 5, and large sprocket 5 is driven by chain 3 and motor 10; Turnbuckle screw 8 and pressure spring 9; Controller static limit pile 14 is set on push handle 16, and controller dynamic limit pile 15 is fixedly set by screw 18 on controller turning handle 13.

[0018] The non-operation walking wheel 2, the operation driving wheel 4, and the plowshare 6 are arranged in the following order: from left to right, in order: non-operation walking wheel 2----operation driving wheel 4----plowshare 6, left during operation March.

[0019] Controller dynamic spacer pile 15 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com