Steamed bread aging extender and preparation method thereof

An extension agent and a technology for steamed bread, which are applied in the field of steamed bread aging extension agent and its preparation, can solve the problems of secondary pollution of steamed bread, small radius, and no fresh-keeping method for steamed bread, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

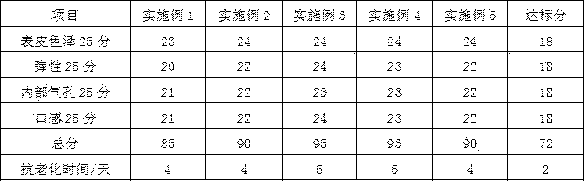

Examples

Embodiment 1

[0015] A steamed bread aging prolonging agent, comprising: 10 parts of soybean oil, 10 parts of sucrose, 0.2 part of lecithin, 0.1 part of sodium stearoyl lactylate, 0.1 part of glycerin, 0.05 part of polyglycerol ricinoleate, 60 parts of water share.

[0016] The steamed bread aging prolonging agent described above is prepared according to the following steps:

[0017] (1) Weigh each component according to parts by weight;

[0018] (2) Add sucrose, sodium stearoyl lactylate, glycerin and polyglycerol ricinoleate into water, stir at 50°C for 15 minutes until well mixed, then add soybean oil and lecithin, and continue stirring for 10 minutes;

[0019] (3) Homogenize the mixture prepared in step (2) in a high-pressure homogenizer with a pressure of 40 MPa, and after homogenizing twice, the steamed bun aging prolonging agent is obtained.

Embodiment 2

[0021] A steamed bread aging prolonging agent, comprising, by weight components: 12 parts of soybean oil, 15 parts of sucrose, 0.3 part of lecithin, 0.2 part of sodium stearoyl lactylate, 0.2 part of glycerin, 0.05 part of polyglycerol ricinoleate, 68 parts of water share.

[0022] The steamed bread aging prolonging agent described above is prepared according to the following steps:

[0023] (1) Weigh each component according to parts by weight;

[0024] (2) Add sucrose, sodium stearoyl lactylate, glycerin and polyglycerol ricinoleate into water, stir at 52°C for 15 minutes until well mixed, then add soybean oil and lecithin, and continue stirring for 10 minutes;

[0025] (3) Homogenize the mixture prepared in step (2) in a high-pressure homogenizer with a pressure of 45 MPa, and after homogenizing twice, the steamed bread aging prolonging agent is obtained.

Embodiment 3

[0027] A steamed bread aging prolonging agent, comprising, by weight components: 15 parts of soybean oil, 16 parts of sucrose, 0.4 part of lecithin, 0.3 part of sodium stearoyl lactylate, 0.3 part of glycerin, 0.06 part of polyglycerol ricinoleate, and 70 parts of water share.

[0028] The steamed bread aging prolonging agent described above is prepared according to the following steps:

[0029] (1) Weigh each component according to parts by weight;

[0030] (2) Add sucrose, sodium stearoyl lactylate, glycerin and polyglycerol ricinoleate into water, stir at 55°C for 20 minutes until well mixed, then add soybean oil and lecithin, and continue stirring for 15 minutes;

[0031] (3) Homogenize the mixture prepared in step (2) in a high-pressure homogenizer at a pressure of 50 MPa, and after homogenizing three times, the steamed bread aging prolonging agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com