Real-time optimizing control system and method for ammonia spraying partitions of SCR device

An optimized control and denitrification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of inability to truly and comprehensively understand the internal conditions of SCR, difficult to control operating costs, and low level of operation management, and achieve maximum improvement. The effect of denitration efficiency, improving service life and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with the accompanying drawings.

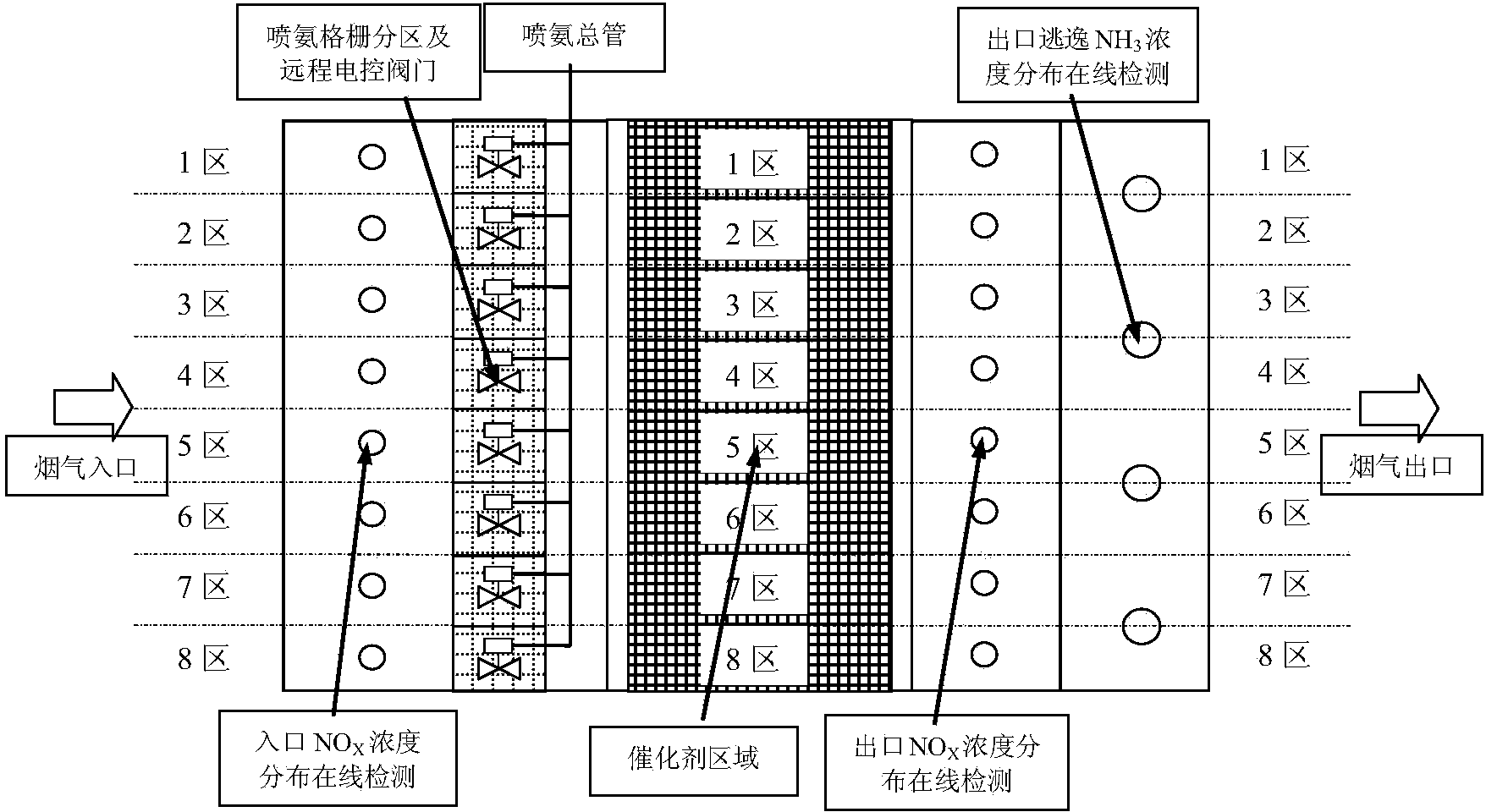

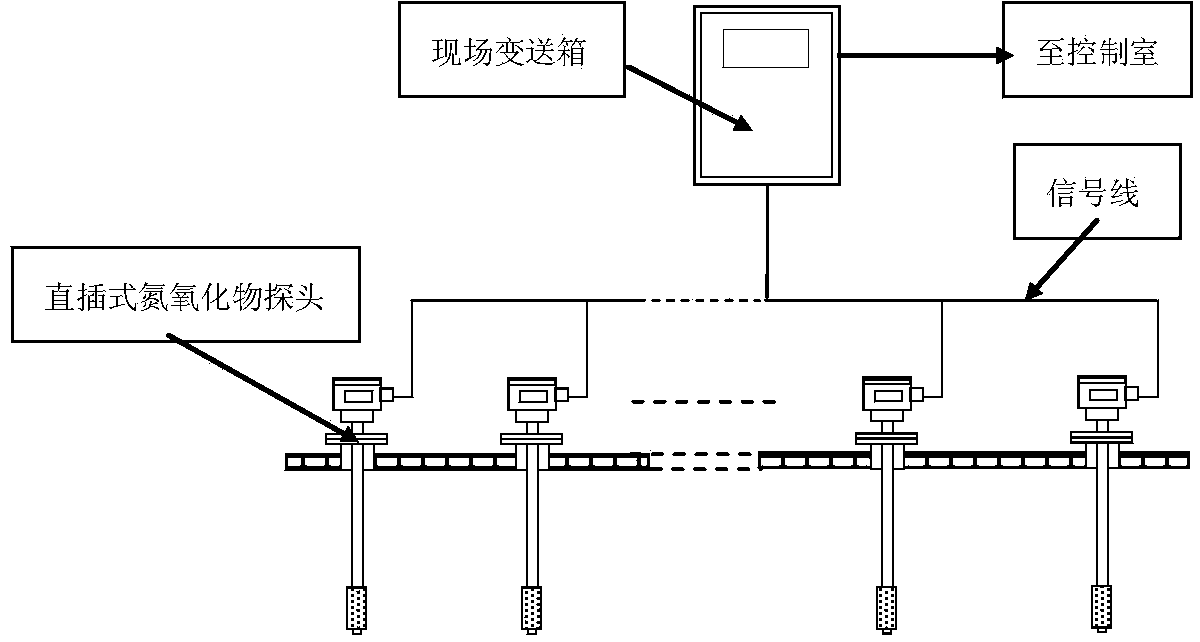

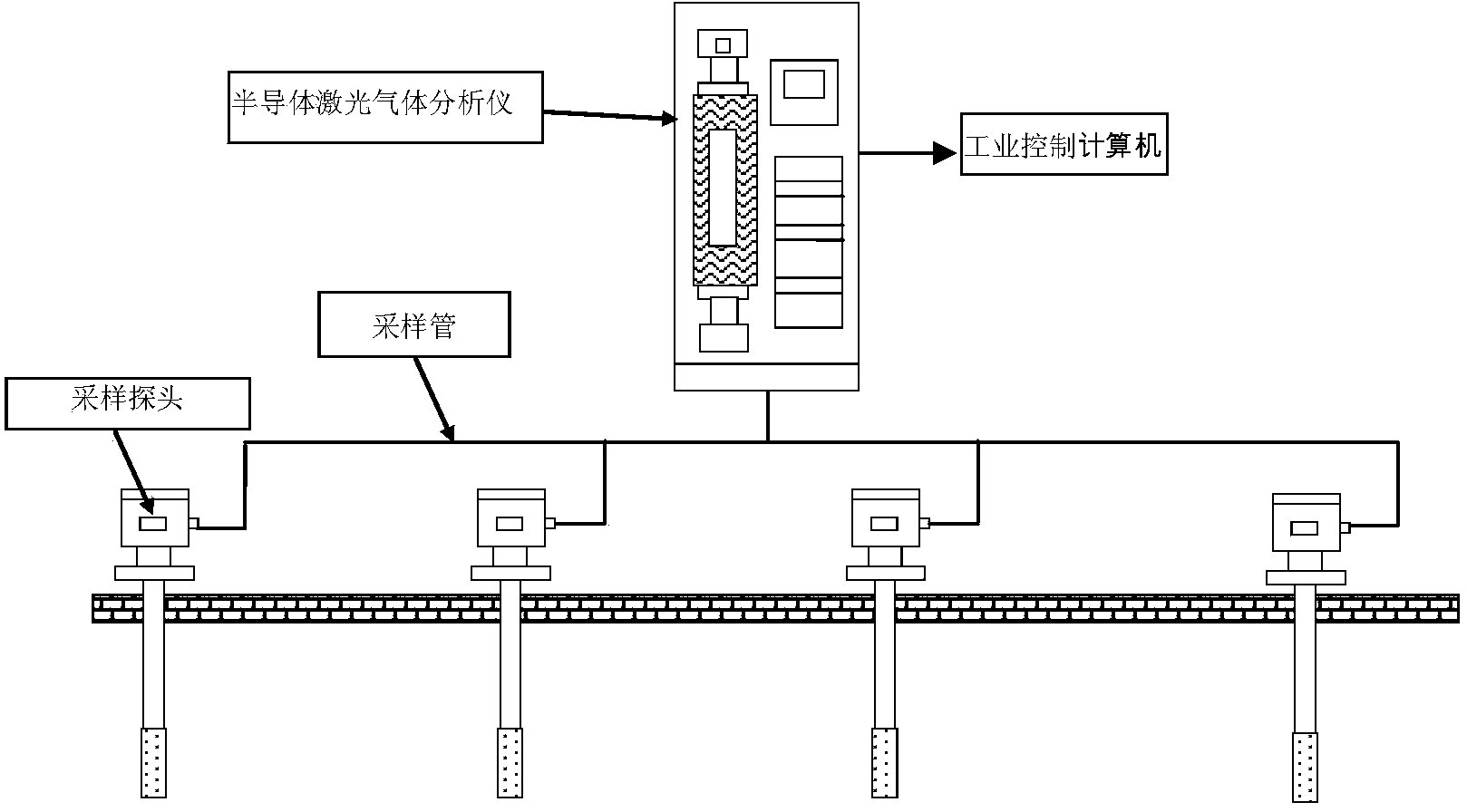

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the real-time optimization control system of the denitrification device ammonia injection zone of the present invention includes NO X Concentration distribution real-time online analysis subsystem, NH 3 Concentration distribution online analysis subsystem, industrial control computer, remote electronic control valve. The NO X The real-time online analysis subsystem of concentration distribution includes nitrogen oxide probe and on-site transmission box. The nitrogen oxide probe is an in-line nitrogen oxide probe. The NH 3 The concentration distribution online analysis subsystem includes a semiconductor laser gas analyzer, a sampling probe, and the NH 3 The concentration distribution on-line analysis subsystem adopts sampling probes for multi-point continuous sampling. Each ammonia injection grid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com