Manufacture Process of Guide Vane of Large Water Turbine

A water turbine and guide vane technology, which is applied to manufacturing tools, workpiece edge parts, metal processing equipment, etc., can solve the problem of insufficient machining allowance of movable guide vanes, reduce the quality and stability of movable guide vanes, and affect the assembly of movable guide vanes. Accuracy and other issues, to achieve the effect of improving tissue and mechanical properties, improving quality and stability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

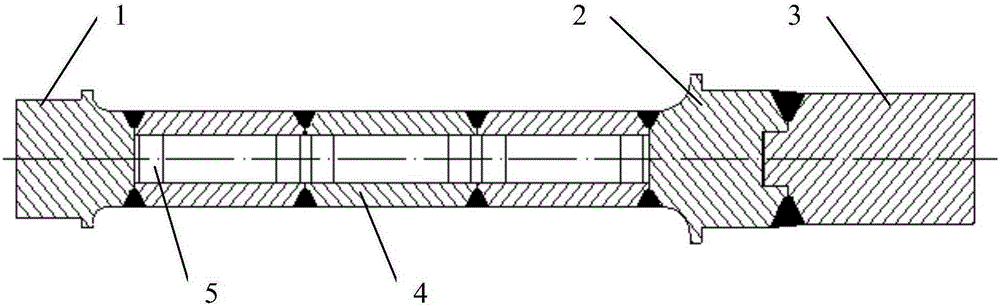

[0024] The invention is a manufacturing process method for reducing the manufacturing cost of guide vanes of large water turbines and improving the quality of guide vanes of water turbines. The specific embodiment of the present invention is:

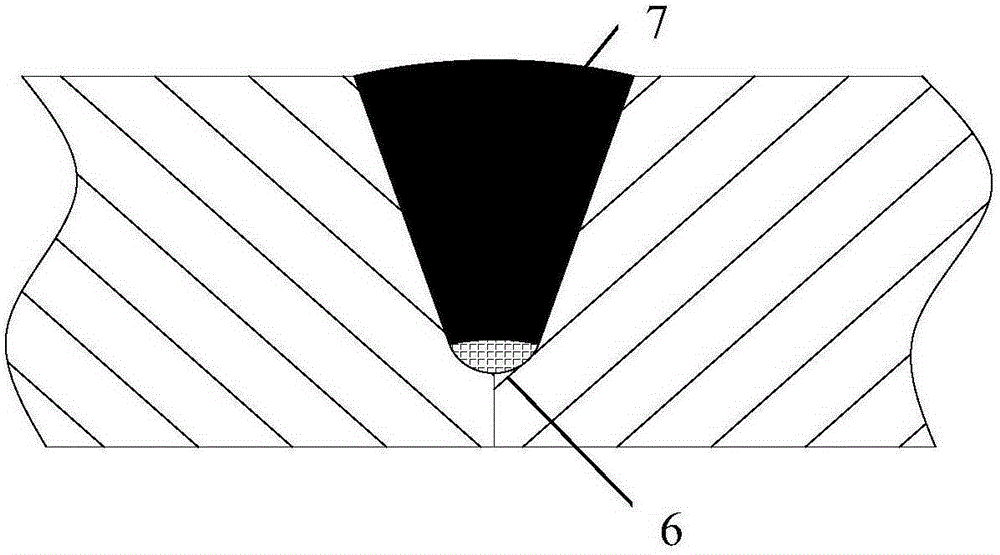

[0025] 1) Valve body preparation: the valve body adopts a hollow casting split structure, the material is ZG06Cr13Ni4Mo, and the valve body shape line and U-shaped large blunt edge welding groove are processed;

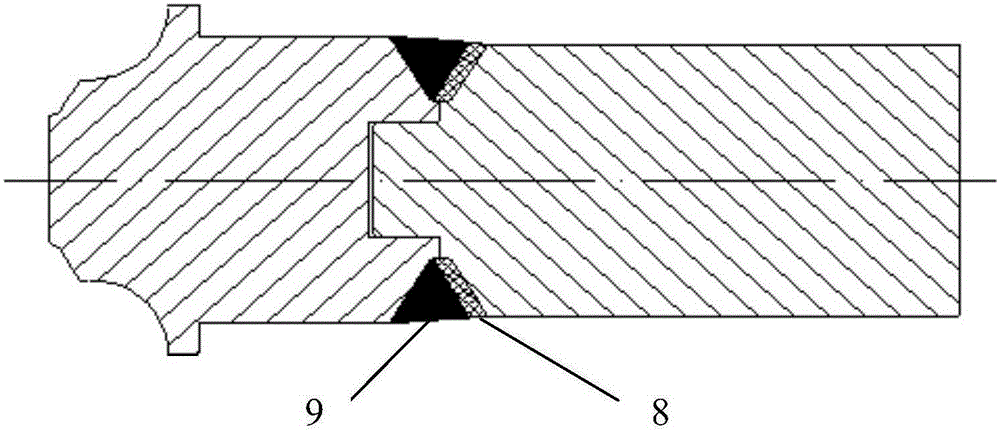

[0026] 2) Long shaft material preparation: the long shaft shoulder and shaft body are made of castings, the material of the shaft shoulder is ZG06Cr13Ni4Mo, and the material of the shaft body is ZG20SiMn, and the contour and welding groove are processed;

[0027] 3) Short shaft material preparation: The short shaft is made of castings, the material is ZG06Cr13Ni4Mo, and the U-shaped large blunt edge welding groove is processed;

[0028] 4) Install the reinforcement plate to prevent welding deformation: assemble the reinforceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com