Automatic wood plate production system for packaged timber

An automatic production and wood technology, which is applied in the direction of wood processing equipment, wooden veneer joints, manufacturing tools, etc., can solve the physical and chemical parameters difficult to achieve packaging construction and other problems, achieve simple structure, low investment in design and production, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

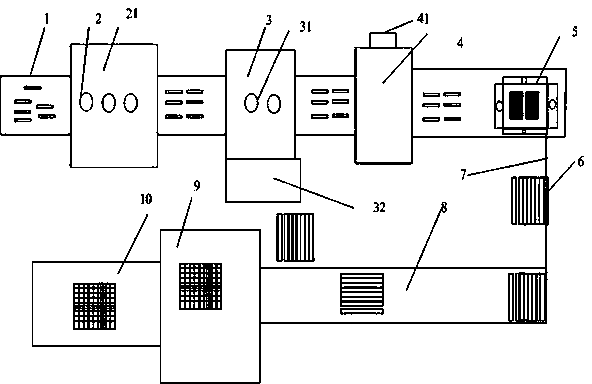

[0017] see figure 1 : A kind of automatic production system of wood pattern plate for packaging wood, including a first conveyor belt 1 and a microwave dryer 2 arranged on the first conveyor belt 1, a double-layer glue spraying machine 3, an air dryer 4, horizontal and vertical typesetting machine 5, and the discharge guide rail 7 arranged at the bottom of the horizontal and vertical typesetting machine 5, and the second conveying belt 1 arranged directly above the discharge guide rail 7, and the heat transfer belt 1 arranged at the end of the second conveying belt 2 away from the discharge guide rail 7 Compression molding machine9.

[0018] The microwave dryer 2 includes a microwave drying chamber and a microwave generator 21 arranged directly above the microwave drying chamber, and the first transmission belt 1 passes through the microwave drying chamber.

[0019] The double-layer type glue spraying machine 3 includes a glue spraying machine room, and the first transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com