Wastewater treatment method for acrylonitrile production and refining process

A wastewater treatment and acrylonitrile technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of complex treatment process, high COD value, high operating cost, etc., and achieve the effect of simple process, thorough removal and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

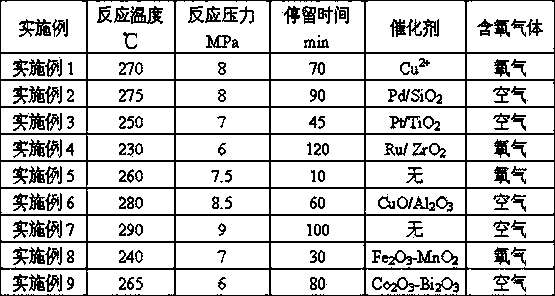

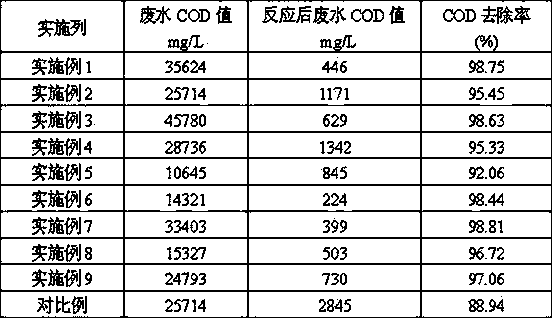

[0011] The waste water from the acrylonitrile production and refining system is mixed with the gas containing elemental oxygen and passed through the wet oxidation reactor. The reaction conditions are shown in Table 1. After the reaction, the waste water is cooled to room temperature by a cooler and separated from the gas and liquid. The COD value of the waste water before the reaction and the value after the reaction are analyzed. See Table 2 for the COD value of the water phase after gas-liquid separation.

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com