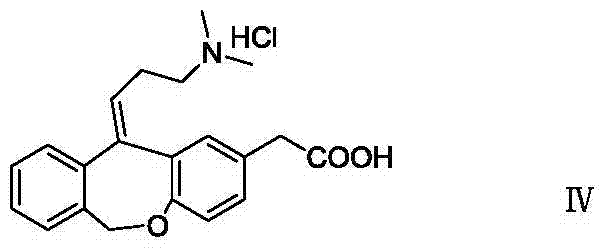

Novel method for preparing olopatadine hydrochloride by using high-activity organic zinc reagent

A technology of olopatadine and high-activity zinc, which is applied in the field of preparing olopatadine hydrochloride with high-activity organozinc reagent, can solve the problems of complicated post-processing, long process steps, etc., and achieves simplified post-processing process, simple operation and product high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

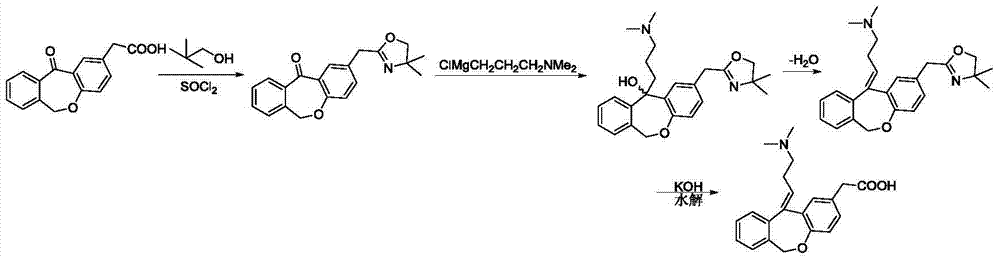

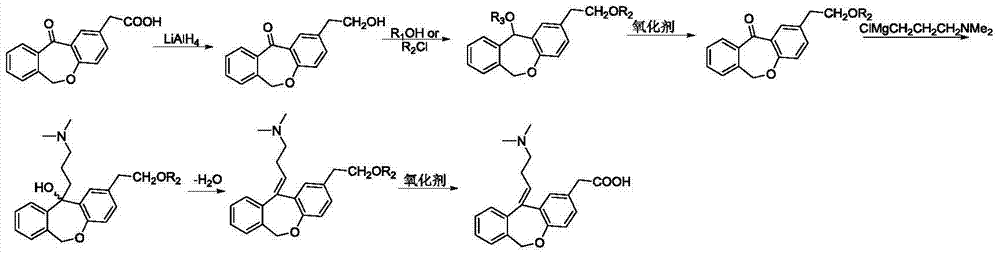

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Highly Active Organozinc Reagent

[0036] Under the protection of nitrogen, add 3-bromo-N,N-dimethylpropanamine (5.0g, 30mmol) and 32ml of anhydrous tetrahydrofuran to the reaction flask, stir and cool to 10-20℃, add activated zinc powder (3.9 g, 60mmol), after the addition, the temperature was controlled at 20-30°C and stirred for 0.5h, heated to reflux (65-70°C), and stirred for 5-6h. The resulting reaction solution is a highly active organic zinc reagent.

[0037] Preparation of Crude Olopatadine

[0038] Dissolve isoket acid (4.0g, 15mmol) in 12ml of tetrahydrofuran, stir, dissolve and clarify, then drop into the above-mentioned highly active organic zinc reagent at a temperature of 0-10°C, after about 0.5h, raise the temperature to 20-25°C and stir to react After 16 hours, HPLC tracked the end point of the reaction, and the purity was 37.6%.

[0039] Cool the above reaction solution, add 25ml of water for extraction, adjust the pH of the water pha...

Embodiment 2

[0043] Preparation of lithium naphthalene reagent

[0044] Under the protection of nitrogen, lithium metal (0.4 g, 60 mmol) was added to anhydrous naphthalene (2.6 g, 20 mmol), and the temperature was controlled at 20-25° C. and stirred for 2 h to obtain lithium naphthalene reagent.

[0045] Preparation of Highly Active Organozinc Reagent

[0046] Under the protection of nitrogen, add 3-bromo-N,N-dimethylpropanamine (5.0g, 30mmol) and 32ml of anhydrous tetrahydrofuran to the reaction flask, stir and cool to 10-20℃, add zinc bromide (13.5 g, 60 mmol), stirred for 10 min, added dropwise the above-mentioned naphthalene lithium reagent, after the reaction temperature was stabilized, heated to reflux (65-70°C), and stirred for 5-6 h. The resulting reaction solution is a highly active organic zinc reagent.

[0047] Preparation of Crude Olopatadine

[0048] Dissolve isoket acid (4.0g, 15mmol) in 12ml of tetrahydrofuran, stir to dissolve and clarify, then drop into the above-mentio...

Embodiment 3

[0053] Preparation of Highly Active Organozinc Reagent

[0054] Under the protection of nitrogen, add 3-bromo-N,N-dimethylpropylamine (5.0g, 30mmol), zinc bromide (13.5g, 60mmol) and 32ml of anhydrous tetrahydrofuran into the reaction flask, stir and cool to 10-20 ℃, add metal lithium (0.4g, 60mmol) in batches, after the reaction temperature stabilizes, heat to reflux (65-70℃), and stir for 5-6h. The obtained reaction solution is the highly active organic zinc reagent.

[0055] Preparation of Crude Olopatadine

[0056]Dissolve isoket acid (4.0g, 15mmol) in 12ml of tetrahydrofuran, stir, dissolve and clarify, then drop into the above-mentioned highly active organic zinc reagent at a temperature of 0-10°C, after about 0.5h, raise the temperature to 20-25°C and stir to react After 16 hours, HPLC tracked the end point of the reaction, and the purity was 75.2%.

[0057] Cool the above reaction solution, add 25ml of water for extraction, adjust the pH of the water phase to 4.0-4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com