Antistatic non-plasticized PVC composite

A non-plasticized, composite technology, applied in the field of polymer processing materials, can solve the problems of low antistatic efficiency, small amount of addition, and long-lasting antistatic effect, etc., and achieve high-efficiency and long-lasting antistatic performance, good rigidity and toughness , long-lasting antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21

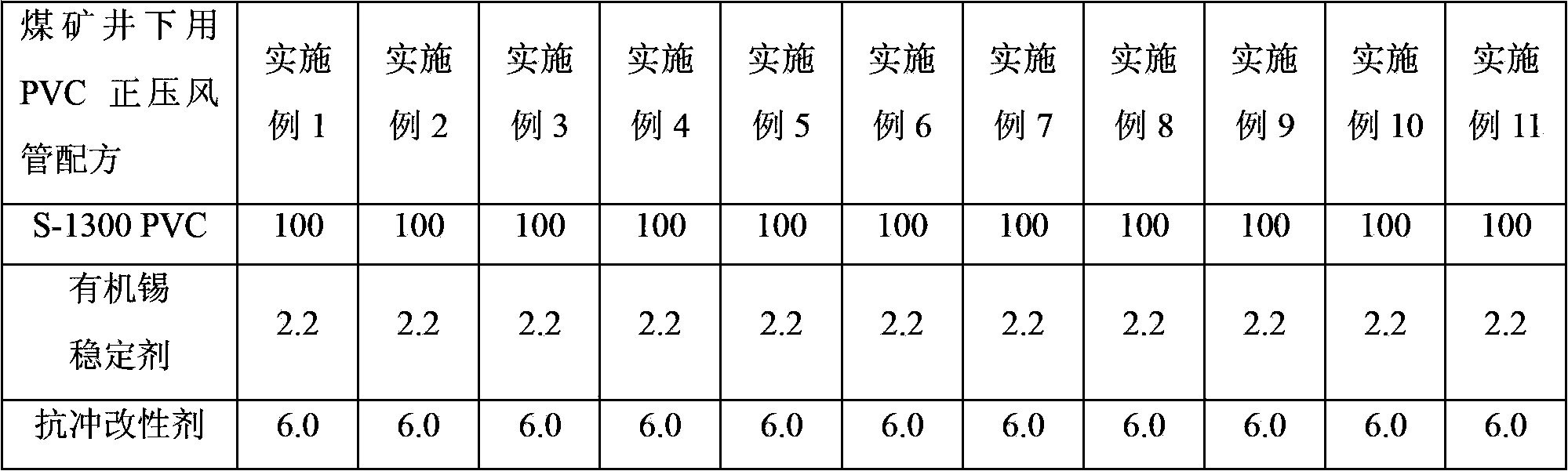

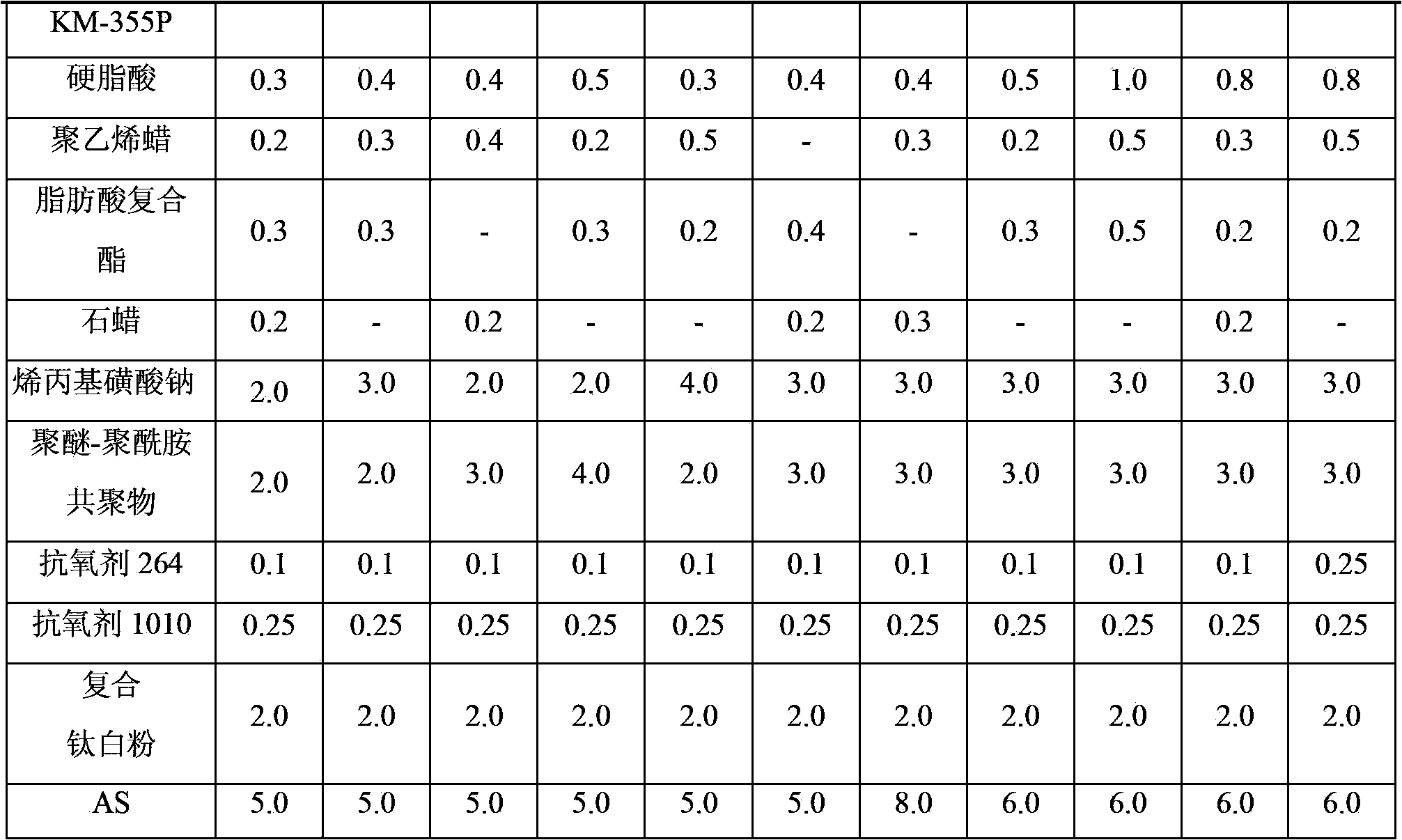

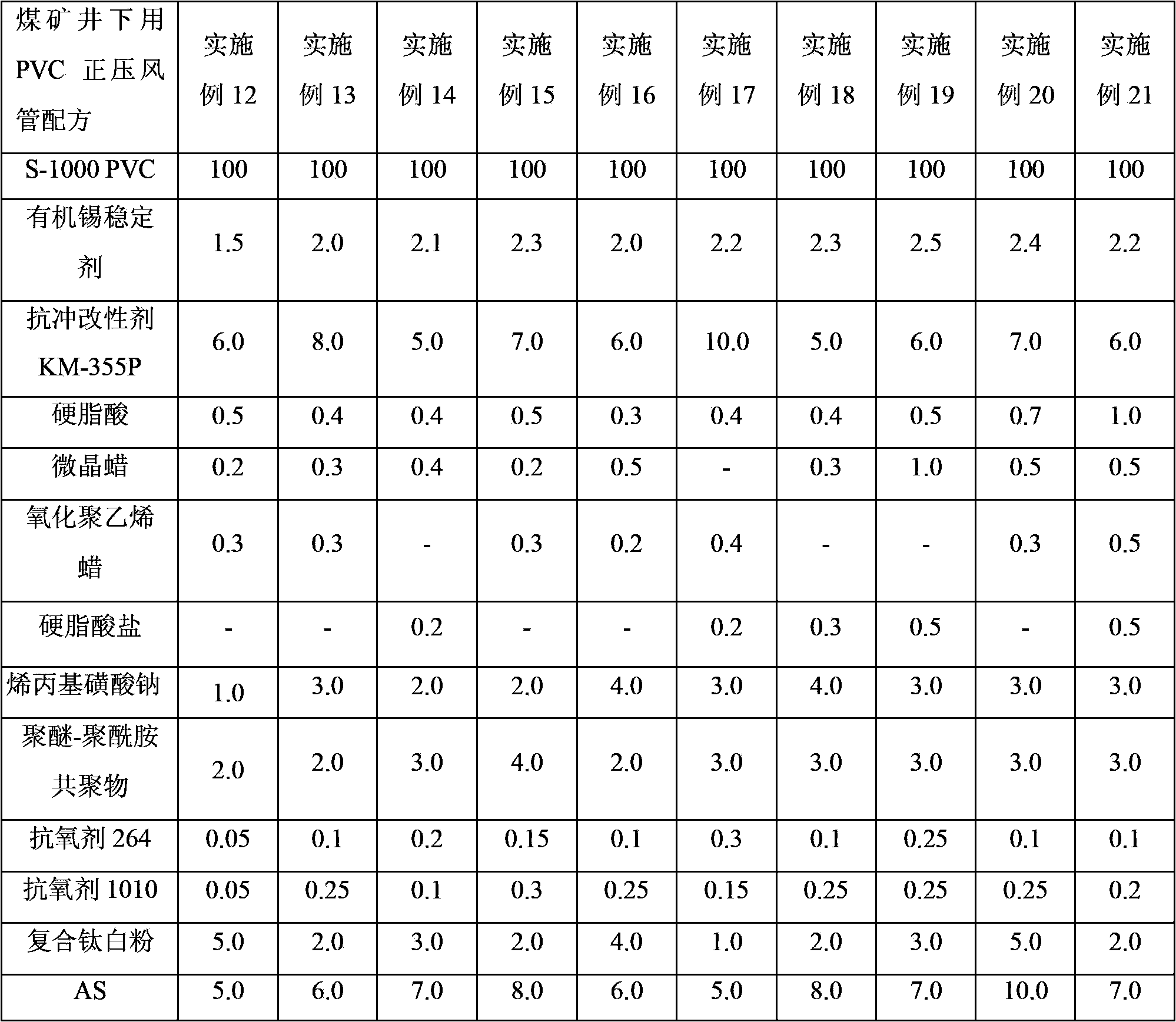

[0018] Examples 1 to 21 are examples of the application of the antistatic unplasticized PVC composition of the present invention to PVC positive pressure air ducts for underground coal mines, and the proportioning components are shown in Tables 1 to 2. Wherein embodiment 11 is the best implementation mode. The sodium allyl sulfonate used in Examples 1 to 21 is ATMER190 produced by Ciba Specialty Chemicals of Switzerland, and the polyether-polyamide copolymer is P-18 produced by Ciba Specialty Chemicals of Switzerland.

[0019] Table 1 Embodiment 1 ~ 11 antistatic non-plasticized PVC composition formulation components (by weight)

[0020]

[0021]

[0022] Table 2 The formulation components of the antistatic unplasticized PVC composition of Examples 12 to 21 (by weight)

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com