A two-component ultra-low density fireproof silicone foam material and its preparation process

An ultra-low density, silicone foam technology, applied in the field of polymer fireproof materials, can solve the problems of difficult to prepare foamed silicone rubber with complex shapes, high production conditions, complicated operation methods, etc., and achieves easy construction and replacement, The effect of convenient construction and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Each component in this embodiment is measured in parts by mass.

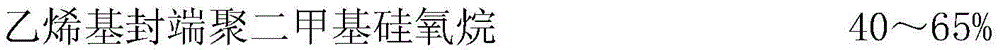

[0034] First, add 50 parts of 1000mPa vinyl-terminated polydimethylsiloxane and 13 parts of 15000mPa dihydroxyl-terminated polydimethylsiloxane into a multifunctional dispersing mixer for mixing. Mixing temperature: 30°C, mixing time : 75min; then add 15 parts of 1500 mesh fumed silica, 10 parts of 1500 mesh wollastonite powder, 6 parts of 1000 mesh aluminum hydroxide, 5 parts of 1000 mesh magnesium hydroxide and stir and mix, mixing time: 45min; then add 0.5 parts of Pt Catalyst, 0.5 parts of carbon black powder were stirred and dispersed, stirring time: 45min; after that, vacuum degassed, time: 90min, to obtain A component;

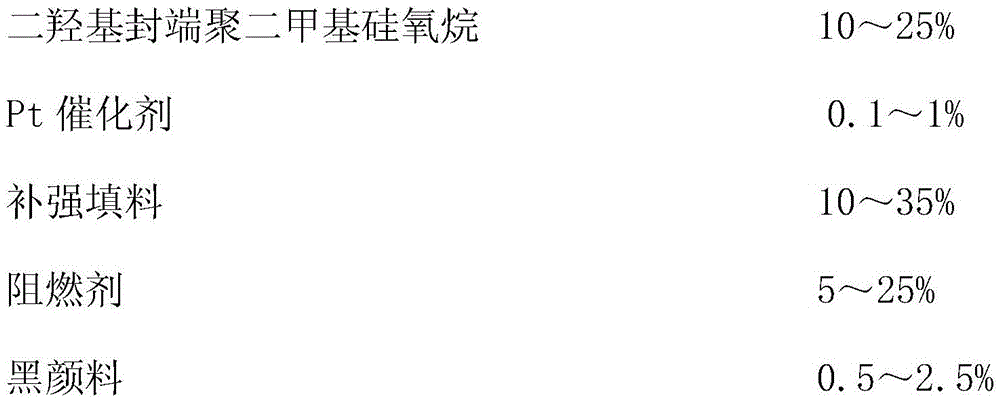

[0035] Next, add 55 parts of 5000mPa vinyl-terminated polydimethylsiloxane, 26 parts of hydrogen-containing silicone oil (hydrogen content 1.5%), 0.9 part of ethylene glycol, and 0.1 part of glycerol into the multifunctional dispersion mixer Mixing, mixing temperature 30°C, mixing...

Embodiment 2

[0038] Each component in this embodiment is measured in parts by mass.

[0039] First, add 45 parts of 2000mPa vinyl-terminated polydimethylsiloxane and 15 parts of 12000mPa dihydroxyl-terminated polydimethylsiloxane into a multifunctional dispersing mixer and mix them. Mixing temperature: 40°C, mixing time : 80min; then add 5 parts of 600 mesh aluminum hydroxide, 5 parts of 600 mesh zinc carbonate, 29 parts of 500 mesh light calcium carbonate and stir and mix, mixing time: 35min; then add 0.1 part of Pt catalyst, 0.5 part of colloidal graphite powder, 0.4 Part of iron oxide black powder was stirred and dispersed, stirring time: 40min; then vacuum degassed, time: 80min, to obtain A component;

[0040] Next, add 45 parts of 4000mPa vinyl-terminated polydimethylsiloxane, 28 parts of hydrogen-containing silicone oil (2% hydrogen content) and 0.5 parts of ethylene glycol into a multifunctional dispersing mixer and mix at a mixing temperature of 25°C , mixing time: 80min; then add...

Embodiment 3

[0043] Each component in this embodiment is measured in parts by mass.

[0044] First, add 65 parts of 2000mPa vinyl-terminated polydimethylsiloxane and 10 parts of 11000mPa dihydroxyl-terminated polydimethylsiloxane into a multifunctional dispersing mixer and mix them. The mixing temperature is 38°C and the mixing time is : 100min; then add 5 parts of chlorinated paraffin, 7 parts of magnesium hydroxide, 10 parts of 2500 mesh fumed silica, 5 parts of 2500 mesh silicon powder and stir and mix, mixing time: 50min; then add 0.5 parts of Pt catalyst, 1.5 parts of carbon Stir and disperse the black powder and 1 part of colloidal graphite powder, stirring time: 38min; then vacuum degassing, time: 85min, to obtain component A;

[0045] Next, add 41 parts of 1000mPa vinyl-terminated polydimethylsiloxane, 36 parts of hydrogen-containing silicone oil (2.5% hydrogen content) and 2.6 parts of ethylene glycol into a multifunctional dispersing mixer and mix at a mixing temperature of 38°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com