Lubricant for drilling fluid and preparation method thereof

A lubricant and drilling fluid technology, applied in the field of lubricants and their preparation, can solve the problems of reducing the lubricating performance of the drilling fluid, increasing the production cost, being difficult to biodegrade, etc. Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

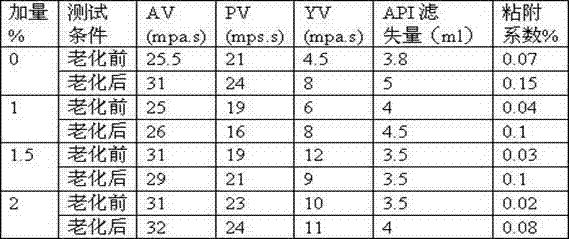

Examples

Embodiment 1

[0019] A non-fluorescent graphite lubricant for drilling fluid, comprising the following raw materials by weight:

[0020] 70 parts of solid graphite;

[0021] 20 parts of potassium humate;

[0022] 10 parts of nonylphenol ether.

[0023] The method for preparing the novel lubricant includes the following steps:

[0024] ①Add the solid graphite of the above formula amount into the pulverizer, and process it into fine graphite powder with a fineness of 200 meshes;

[0025] ② Transfer the graphite fine powder into a container with a mixer, add the nonylphenol ether of the above formula amount while stirring, and make it fully mixed; then add the formula amount of potassium humate and mix evenly;

[0026] ③ Packing by packing machine.

Embodiment 2

[0028] A novel lubricant for drilling fluid, which comprises the following raw materials by weight:

[0029] 80 parts of solid graphite;

[0030] 10 parts potassium humate;

[0031] 10 parts of nonylphenol ether.

[0032] The method for preparing the novel lubricant comprises the following steps:

[0033] ①Add the solid graphite of the above formula amount into the pulverizer, and process it into fine graphite powder with a fineness of 200 meshes;

[0034] ② Transfer the graphite fine powder into a container with a mixer, add the nonylphenol ether of the above formula amount while stirring, and make it fully mixed; then add the formula amount of potassium humate and mix evenly;

[0035] ③ Packing by packing machine.

Embodiment 3

[0037] A non-fluorescent graphite lubricant for drilling fluid, comprising the following raw materials by weight:

[0038] 90 parts of solid graphite;

[0039] 10 parts of nonylphenol ether.

[0040] The method for preparing the novel lubricant comprises the following steps:

[0041] ①Add the solid graphite of the above formula amount into the pulverizer, and process it into fine graphite powder with a fineness of 200 meshes;

[0042] ② Transfer the graphite fine powder into a container with a mixer, add the nonylphenol ether of the above formula amount while stirring, and make it fully mixed;

[0043] ③ Packing by packing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com