Dechlorination method for tar

A tar and dechlorination technology, which is applied in tar processing, petroleum industry, etc., can solve the problems of high equipment requirements, difficult operation, undisclosed temperature, separation time, etc., and achieve the effect of low metal content and increased corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

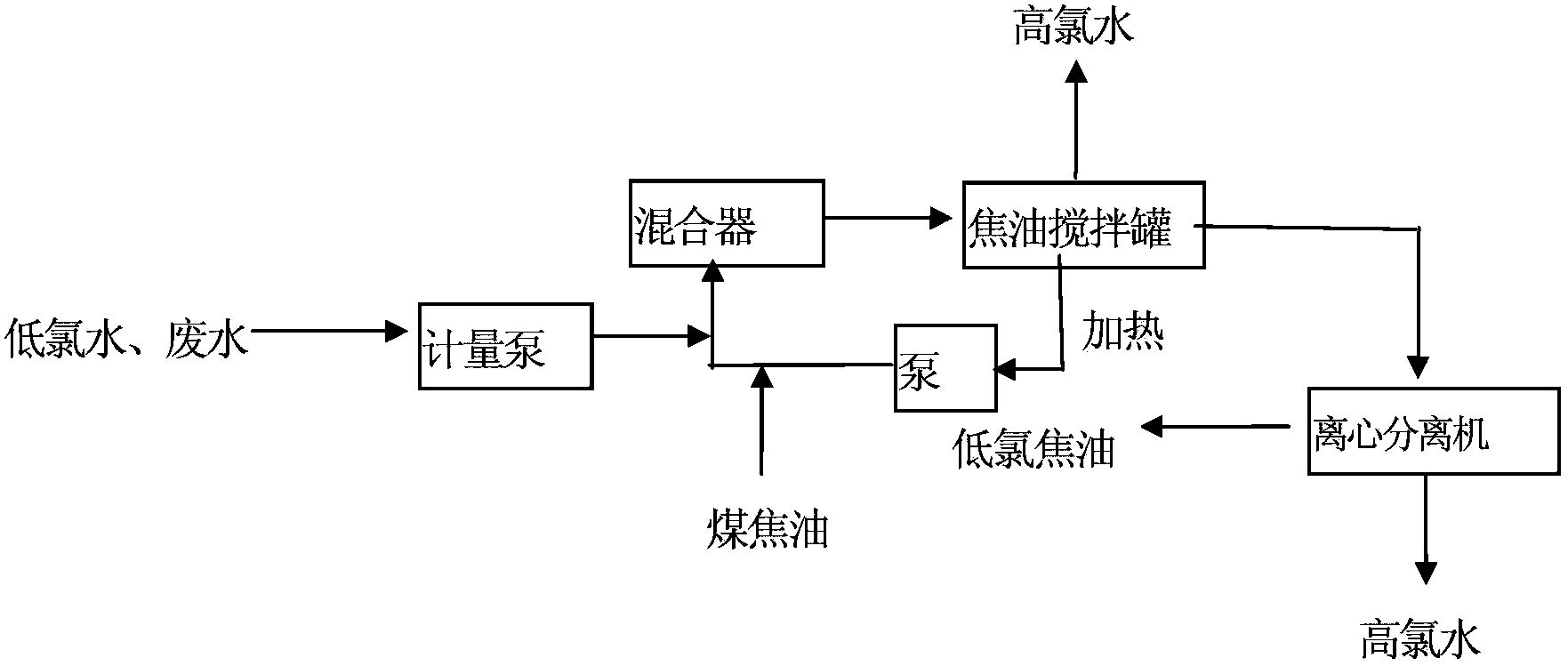

Method used

Image

Examples

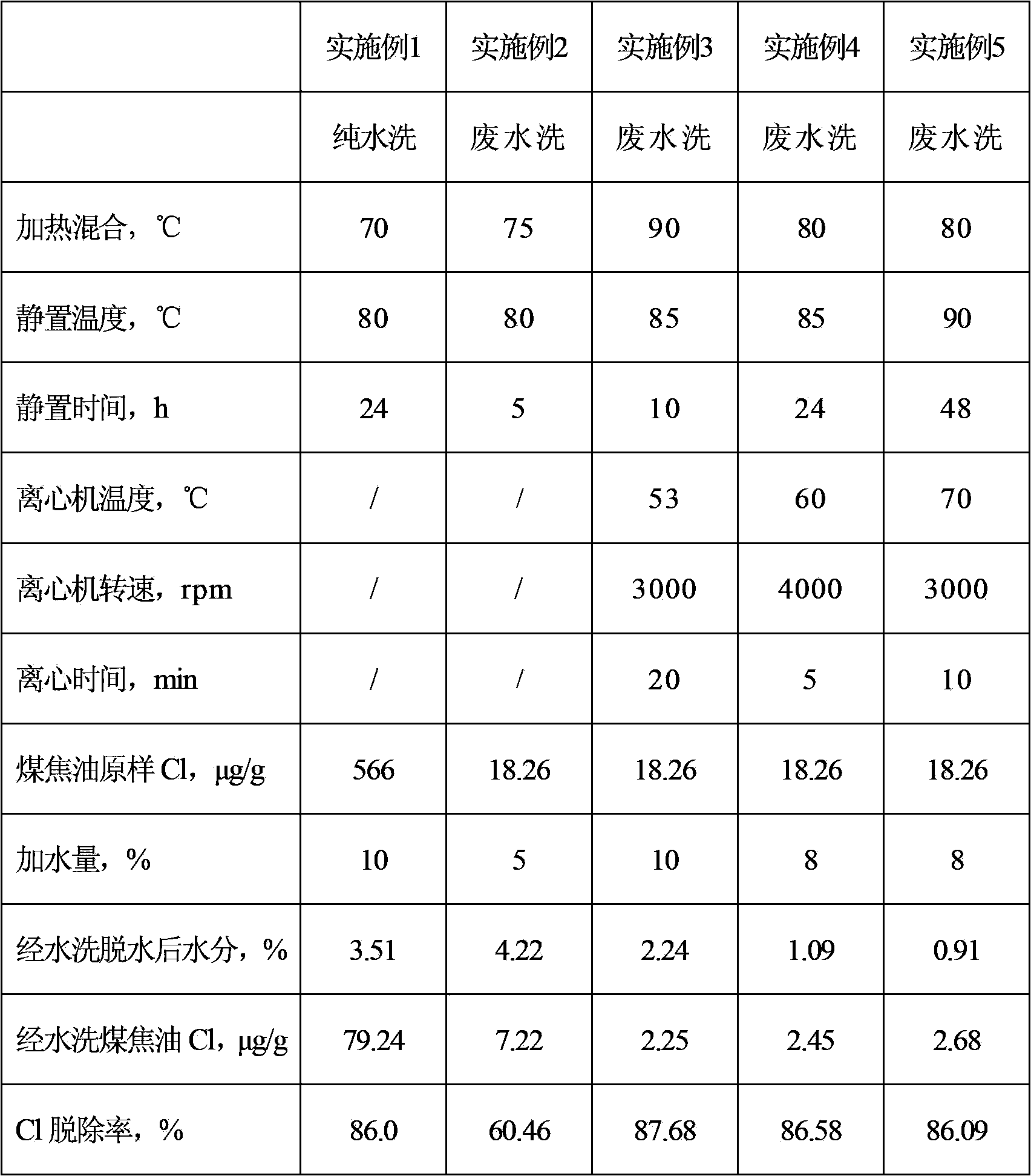

Embodiment 1

[0024] Example 1: Cl 566 μg / g in tar, add 10% pure water, heat to 70°C and mix well, then stand at 80°C for 24h. After separation of the high chlorine aqueous phase, the Cl in the tar was 79.24 μg / g. Cl removal rate is 86.0%.

Embodiment 2

[0025] Example 2: Cl in tar is 18.26 μg / g, add 5% waste water, heat to 75°C and mix well, then stand at 80°C for 5 hours. After separating the high chlorine aqueous phase, the Cl in the tar was 7.22 μg / g. Cl removal rate is 60.46%.

Embodiment 3

[0026] Example 3: Cl in tar is 18.26 μg / g, add 10% waste water, heat to 90°C and mix well, then stand at 85°C for 10 hours, and separate the high-chlorinated aqueous phase once. Incubate again at 53°C and centrifuge at 3000rpm (separation factor 2638G) for 20min. After separating the high chlorine aqueous phase, the Cl2.25μg / g in the tar. Cl - The removal rate is 87.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com