A pretreatment system and method for the production of non-corrosive and sodium-free asphalt

A pretreatment, non-corrosion technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, tar processing, petroleum industry, etc., it can solve the problems of difficult tank turnover, incomplete drainage, poor oil-water mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

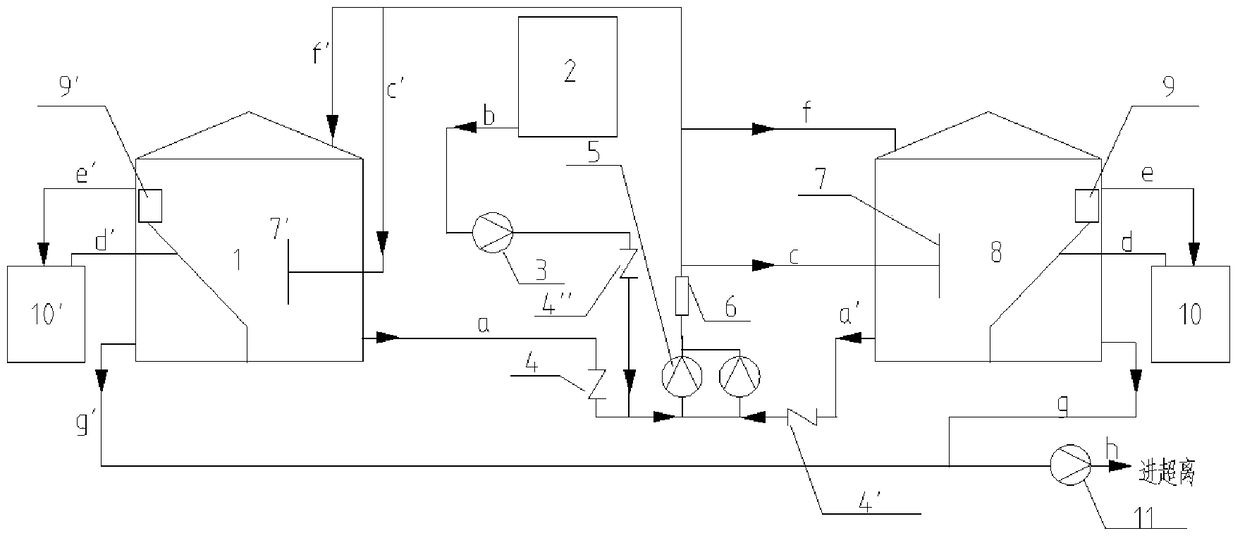

[0055] The tar was received in the raw material tank 1, and its Cl concentration was 20.0 μg / g, and its Na concentration was 9.8 μg / g. The tar was heated to 60°C while receiving the tar. Wastewater tank 2 stock up to 50m 3 , open the relevant valves, start the tar pump 5 and the waste water metering pump 3, the tar passes through the pipeline a, and the waste water passes through the pipeline b respectively through the first check valve 4 and the third check valve 4 "according to the oil-water weight ratio of 12:1 in static Mix in the mixer 6, enter the first feed distributor 7 in the middle of the separator 8 through the pipeline c, and continue to heat the tank to 80 ° C. After the tar has a residence time of about 6 hours, the upper layer of separated water is discharged from the lifting automatic drainage cylinder 9 is discharged, and enters the first ammonia water tank 10 through pipeline d, and ammonia water intermittently sends coal essence residual ammonia water; Afte...

Embodiment 2

[0057] The tar was received in the raw material tank 1, and its Cl concentration was 30.5 μg / g, and its Na concentration was 14.9 μg / g. The tar was heated to 65°C while receiving the tar. Wastewater tank 2 stock up to 100m 3 , open the relevant valves, start the tar pump 5 and the waste water metering pump 3, the tar passes through the pipeline a, and the waste water passes through the pipeline b respectively through the first check valve 4 and the third check valve 4 "according to the oil-water weight ratio of 10:1 in static Mix in the mixer 6, enter the first feed distributor 7 in the middle of the separator 8 through the pipeline c, and continue to heat the tank to 85 ° C. After the tar has a residence time of about 10 hours, the upper layer of separated water is discharged from the lifting automatic drainage cylinder 9 is discharged, and enters the first ammonia water tank 10 through pipeline d, and ammonia water intermittently sends coal essence to circulate ammonia wate...

Embodiment 3

[0059] The tar was received in the raw material tank 8, and its Cl concentration was 40.2 μg / g, and its Na concentration was 16.7 μg / g. Heat the tar to 75°C before washing in boiling water. Wastewater tank 2 stock up to 150m 3, open the relevant valves, start the tar pump 5 and the waste water metering pump 3, the tar passes through the pipeline a', and the waste water passes through the pipeline b respectively through the second check valve 4' and the third check valve 4 "according to the oil-water weight ratio of 8:1 Mix in the static mixer 6, enter the second feed distributor 7' in the middle part of the separator 1 through the pipeline c', and continue to heat to 90 ° C in the tank. After the tar is through the residence time of about 30h, the upper layer of separated water can be The lifting automatic drainage cylinder 9 is discharged, and enters the second ammonia water tank 10' through the pipeline d', and the ammonia water is intermittently sent to the coal essence ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com